V-core 3.2H belt/resonance issues

Hey folks,

I'm looking for some help interpreting these resonance and belt tension graphs. I've upgrades to 3.2H and currently do not have the hybrid belts in place.

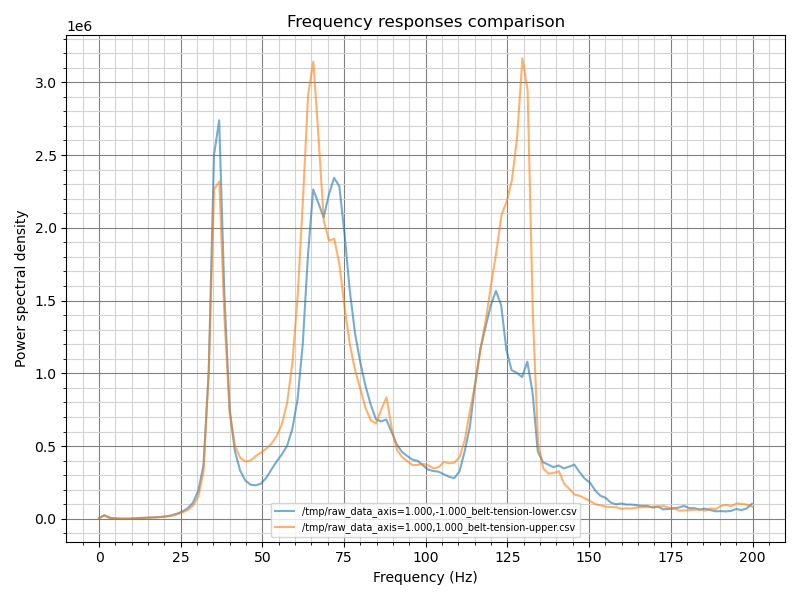

I've tried various belt tensions from ~50-60Hz and I get mostly the same graph shape from all of them; I've had the first two spikes mostly overlapping (a little better than in the example attached) but there's always a spike between 100-150Hz (I've been able to get the third spike to mostly 'line up' on some tests as well, if that makes any difference).

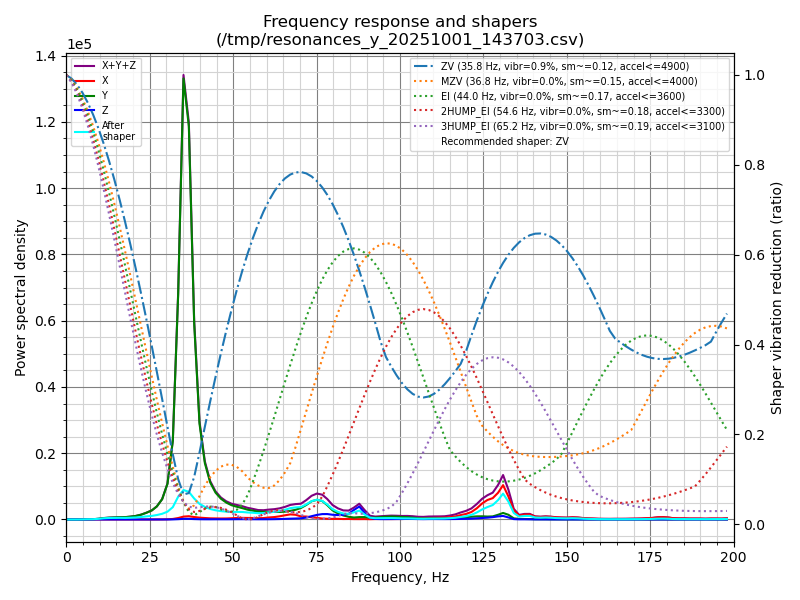

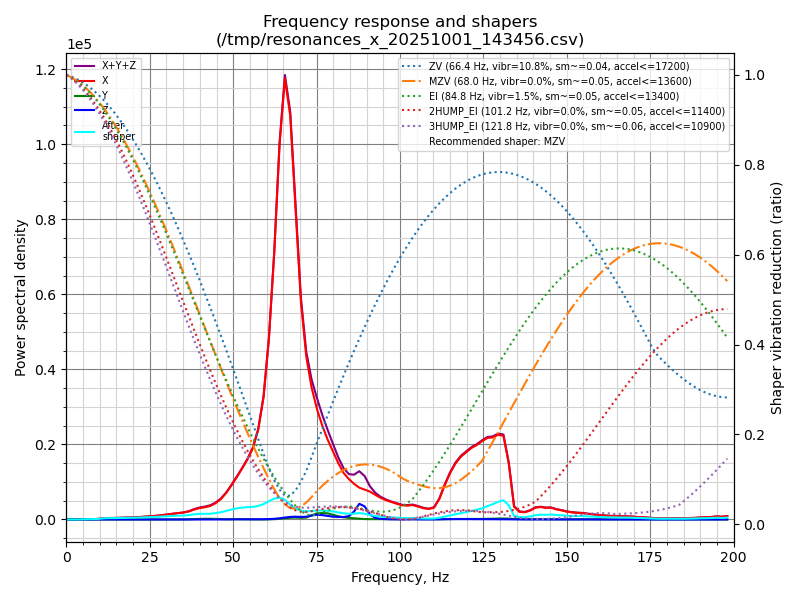

I understand this is likely from the toolhead; I've stripped it down and rebuilt it ensuring all the bolts are snug and all my cables are zip tied up. I made sure my gantry moves freely and there's no noticeable binding when the belts are off.

If I use the resonance analysis tool I can hear some vibration from the toolhead at ~130Hz that quietens if I hold it lightly at various points, but I can't seem to get to the bottom of it or pin point a source. Video of that attached.

If anyone has ideas of what I could/should try to diagnose this further I would greatly appreciate it

I'm looking for some help interpreting these resonance and belt tension graphs. I've upgrades to 3.2H and currently do not have the hybrid belts in place.

I've tried various belt tensions from ~50-60Hz and I get mostly the same graph shape from all of them; I've had the first two spikes mostly overlapping (a little better than in the example attached) but there's always a spike between 100-150Hz (I've been able to get the third spike to mostly 'line up' on some tests as well, if that makes any difference).

I understand this is likely from the toolhead; I've stripped it down and rebuilt it ensuring all the bolts are snug and all my cables are zip tied up. I made sure my gantry moves freely and there's no noticeable binding when the belts are off.

If I use the resonance analysis tool I can hear some vibration from the toolhead at ~130Hz that quietens if I hold it lightly at various points, but I can't seem to get to the bottom of it or pin point a source. Video of that attached.

If anyone has ideas of what I could/should try to diagnose this further I would greatly appreciate it

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)