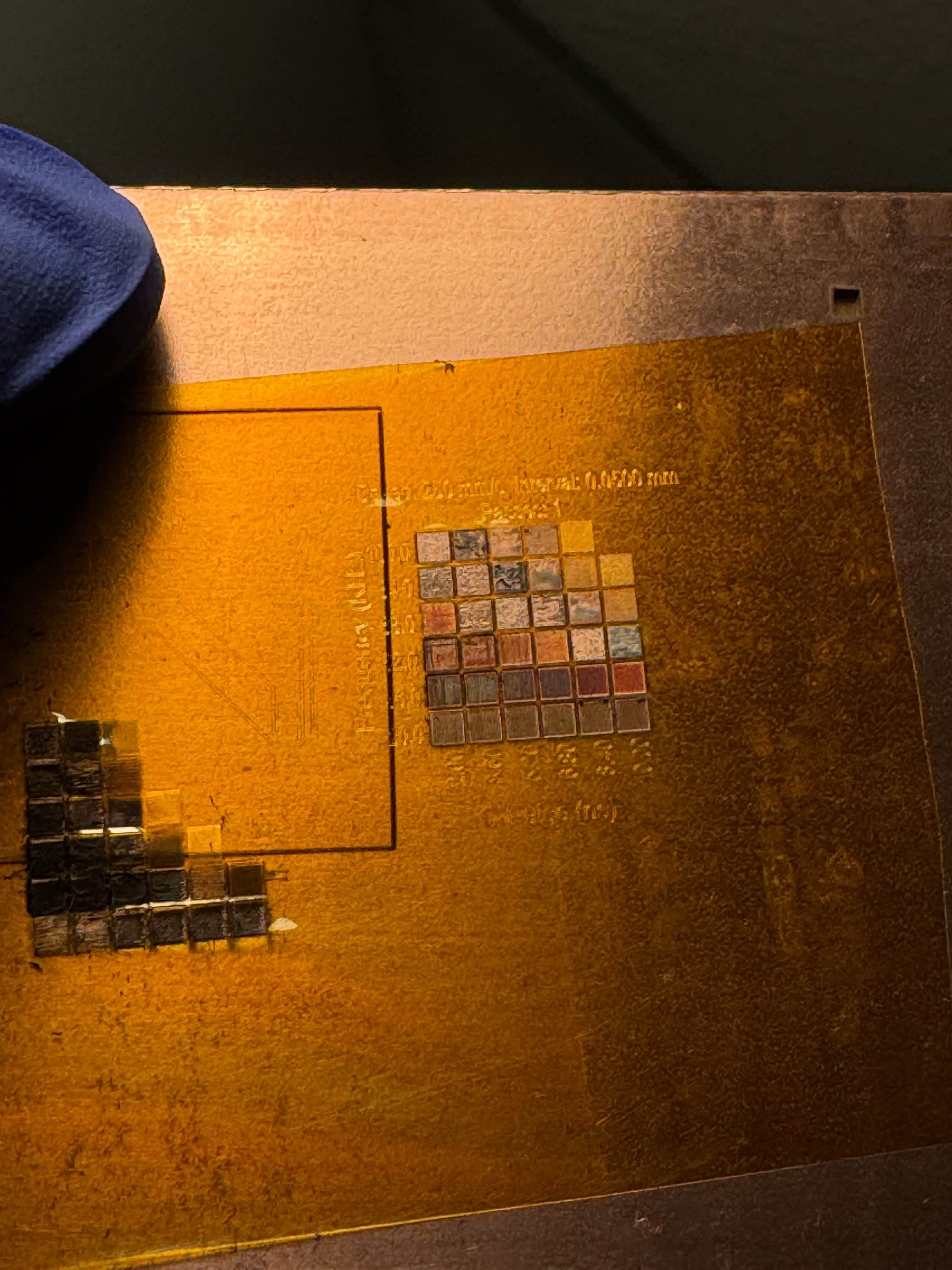

Seve - Got to test kapton tape ablation, its ea...

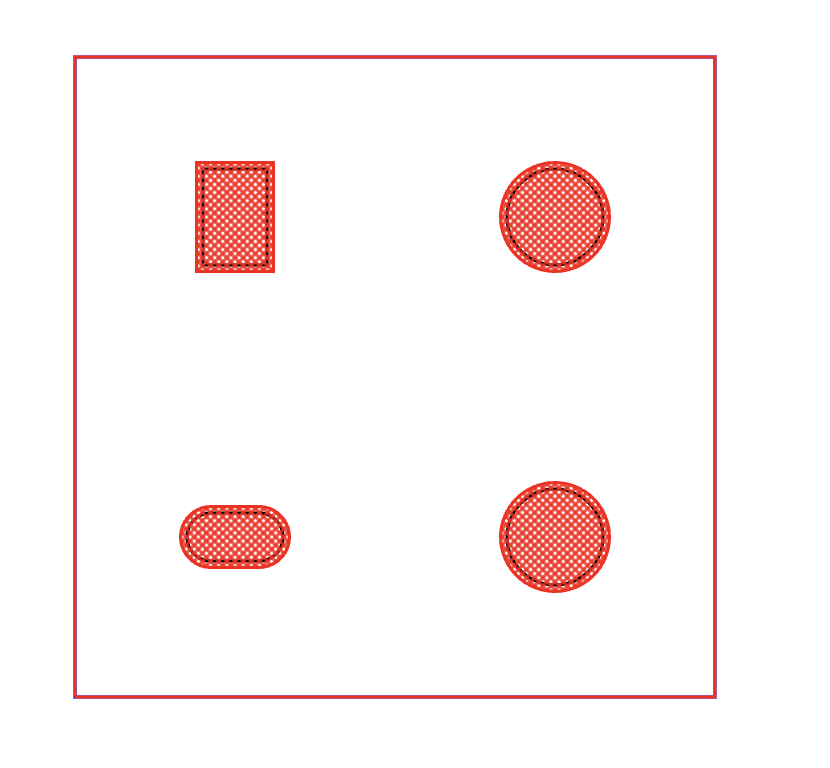

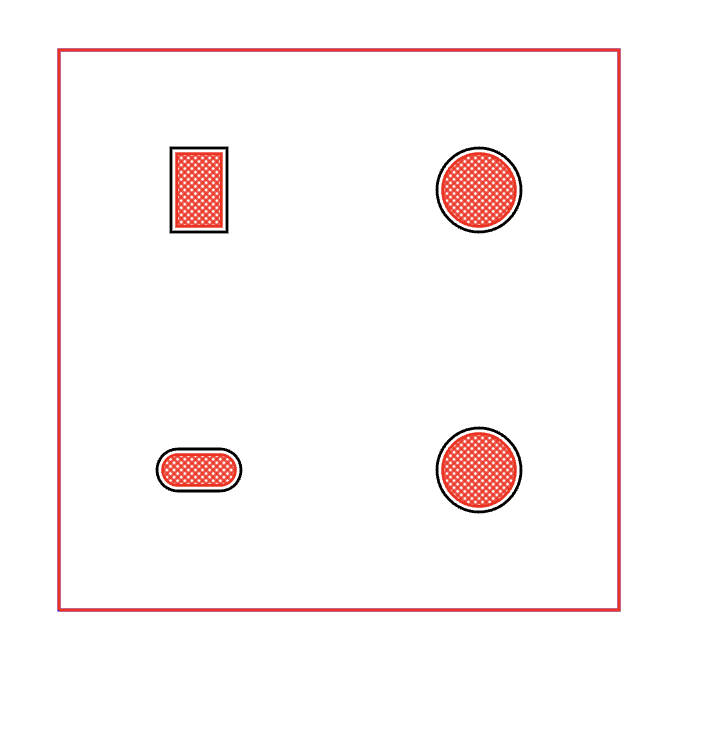

Got to test kapton tape ablation, its easy and you can do it without harming copper, but we should use a crosshatch fill

24 Replies

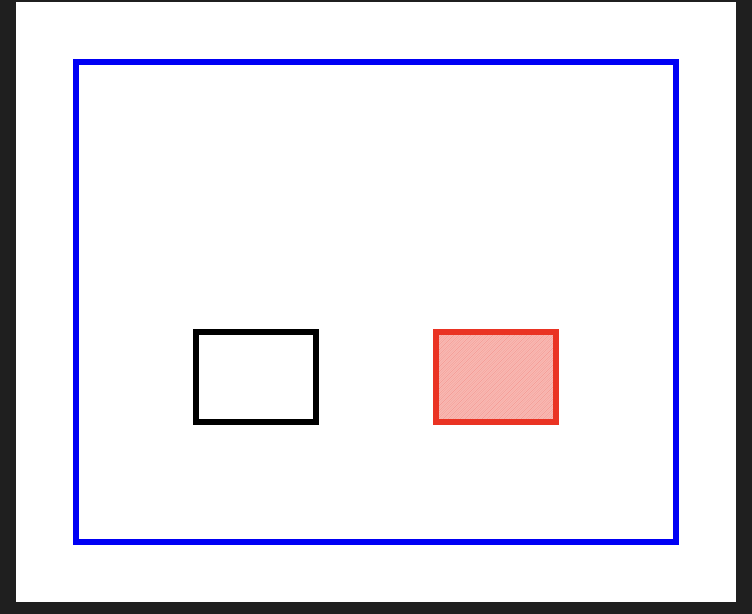

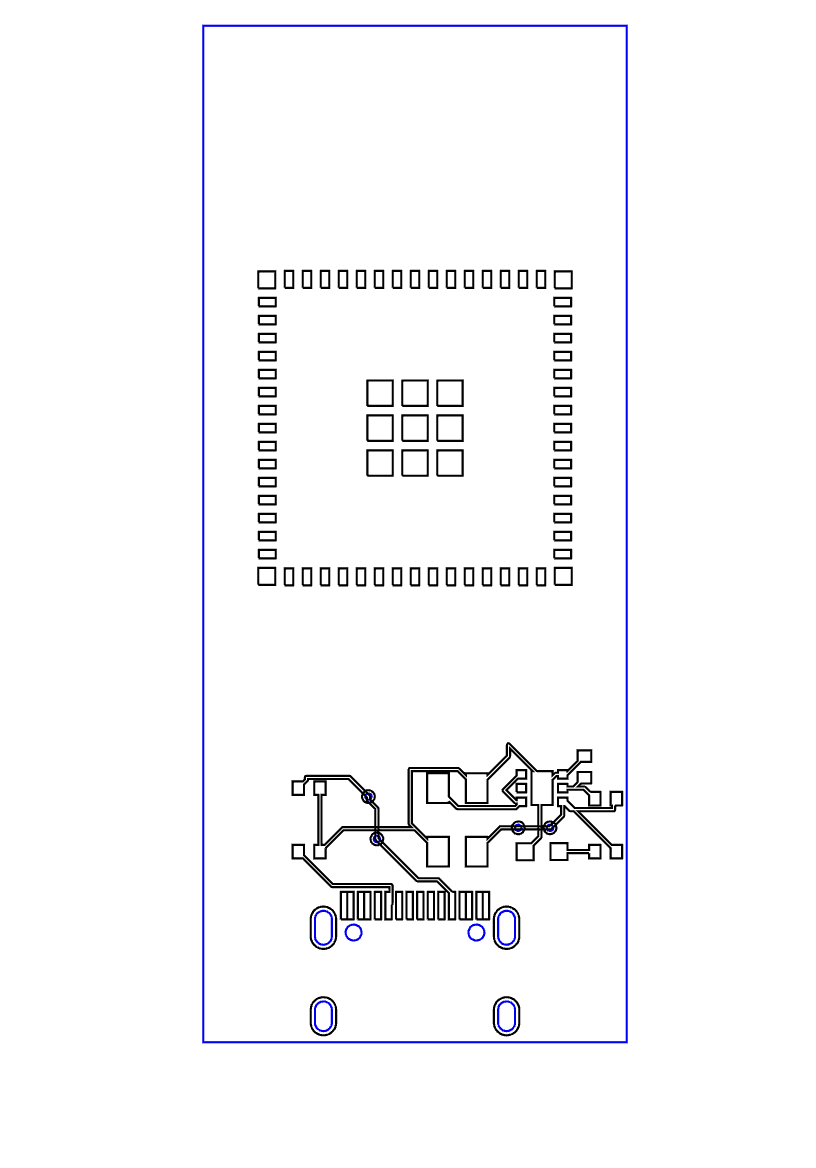

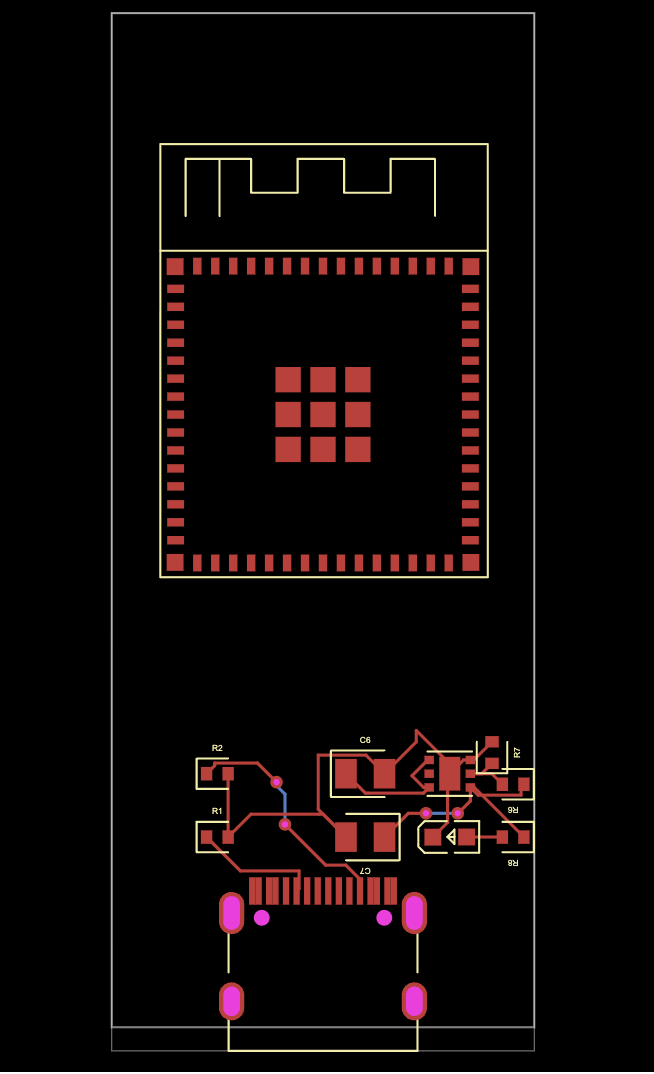

I made some updates on

lbrns repo, here is ex output.

*lbrns2 * file example

check this pr

https://github.com/tscircuit/lbrnts/pull/10

why is it filled tho

did you see Shibo and my discussion around filling as the laser would? i.e. with zfill or crosshatch depending on setting?

if you zoom into the filled shape you'd see it's actually a path not a fill

how/where is that path configured? But yes that is good

ok i think i see it

nice work

🚀

Now I think I should work on adjusted soldermask margin

yes makes sense!

🍻

we can customize the crossHatch looks

do these option costomie how the laser cuts?

@Seve Should I add

soldermaskMargin option here ?

yea i think so, note that it can be negative (and usually will be)

also note that we should add solder mask margin in addition to the existing solder mask margins around components

feel free to join our call today if you'd like btw

we already told him lol

positive and negative margin

nice!

since all of this is fresh, you could try a small PR to https://github.com/tscircuit/circuit-json-to-geometry since this is going to be our base for creating flattenjs geometry in the future (optional)

GitHub

GitHub - tscircuit/circuit-json-to-geometry

Contribute to tscircuit/circuit-json-to-geometry development by creating an account on GitHub.

Need to merge, I didn’t have access for that

I tested some boards with laser.

I think we need to work on RunFrame to support laser lbrn2

like as a preview? When the user goes to export, there's a dialog, we should show the laser preview and allow them to tweak settings there

looks good tho RE: SVG-gen

Yeah, dialog to manage the includedSoldermask,soldermaske margin and includeCupper

yep!