IDEX VAOC Alignment problem - dual color

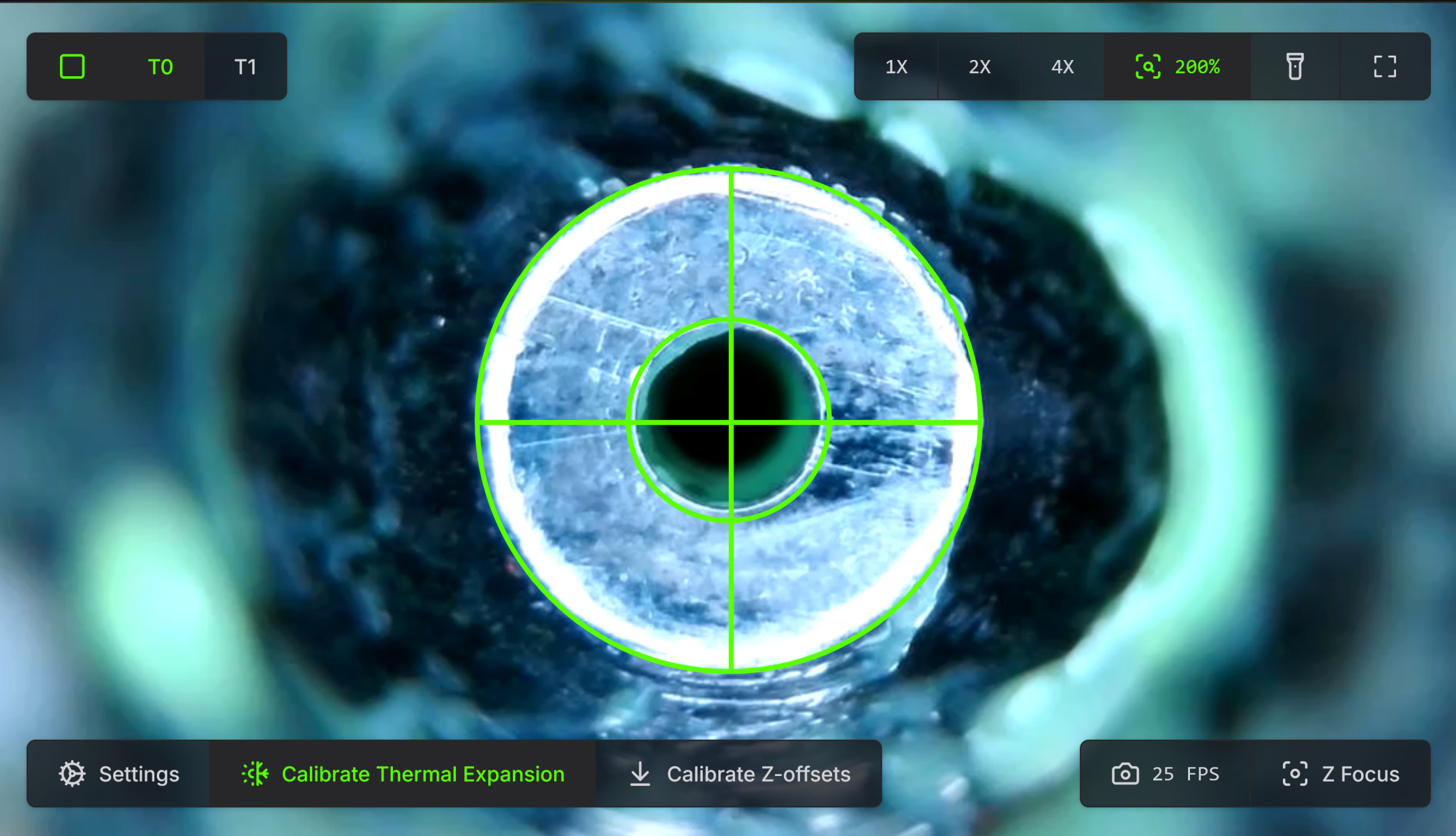

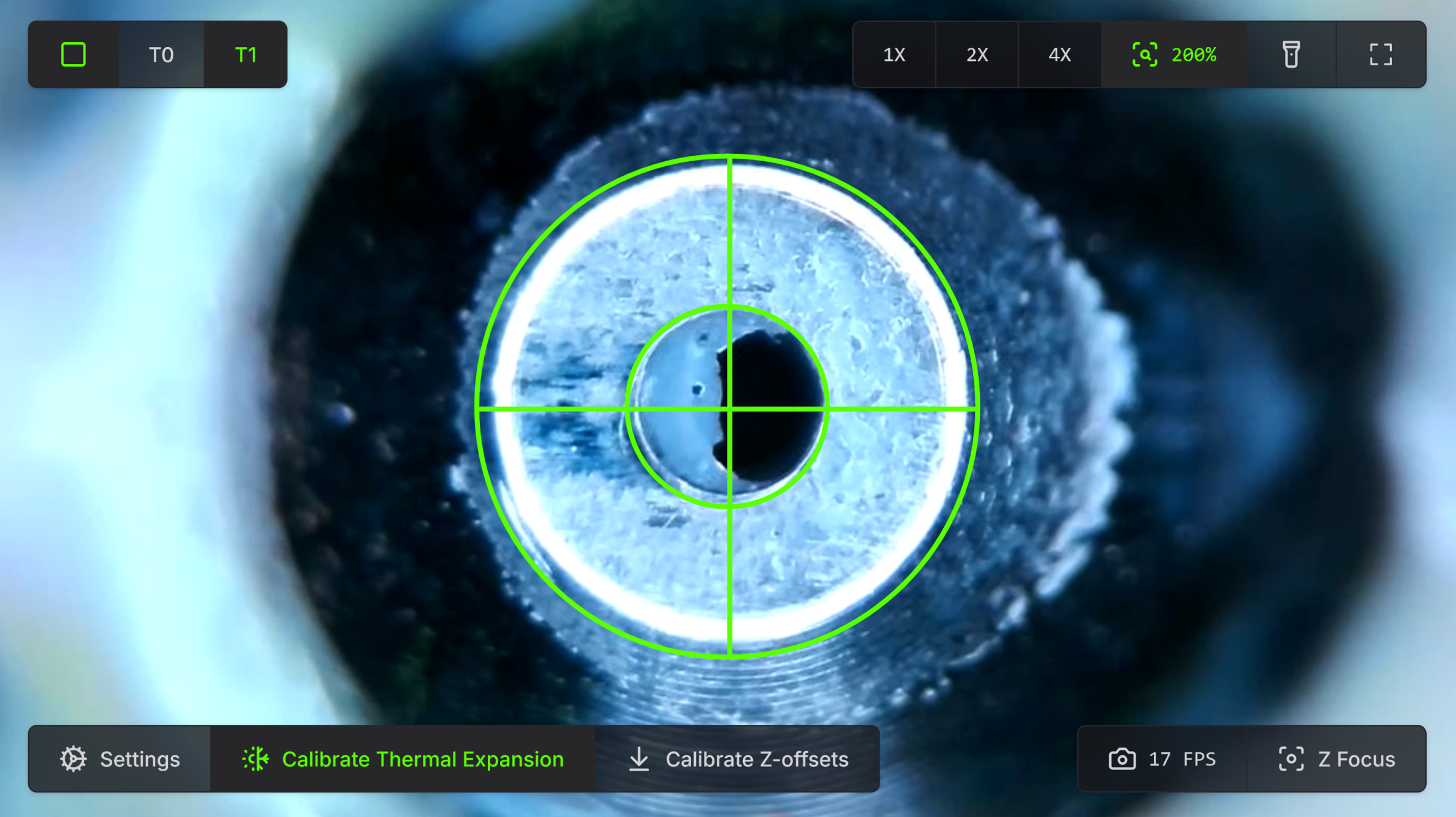

VC4 400 IDEX just finished commissioning. Ran a dual color calibration cube and the 2 parts are off, primarily on the X axis, by approx 0.75 to 0.8mm. 0.4 nozzle, so any small off-center in these particular images is a small fraction of 0.4mm. T1 is printing a full 2 nozzle widths to the left.

The VAOC commissioning guide has been followed, and VAOC calibration done numerous times. CALCULATE_DC_ENDSTOP output has been copied to Printer.cfg and done more than once in hopes that it would work. I now have 4 identical cubes that look like this. Green is T0, Grey is T1. T1 is always laying down 0.8mm to the left side.

X stepper set screws are tight, belts are not slipping from the CNC belt clips. No loose screws that I can find.

Really at a loss. I see Helge Keck is no longer here, but I sure hope someone can assist. IDEX is the entire reason I bought and built this machine.

DC Endstop output:

[dual_carriage]

position_max: 459.560

position_endstop: 459.560

[gcode_macro RatOS]

variable_bed_margin_x: [59.800, 59.560]

[gcode_macro _VAOC]

variable_expected_camera_x_position: 163.126

variable_expected_camera_y_position: 429.744

[gcode_macro T0]

variable_parking_position: -57.800

[gcode_macro T1]

variable_parking_position: 457.560

[gcode_macro _LED_START_PRINTING]

gcode:

Note that I left in the prior values for the DC Endpoint, commented out in printer.cfg, for reference. Parts printed identically.

Any assistance would be welcome! And thanks in advance.

The VAOC commissioning guide has been followed, and VAOC calibration done numerous times. CALCULATE_DC_ENDSTOP output has been copied to Printer.cfg and done more than once in hopes that it would work. I now have 4 identical cubes that look like this. Green is T0, Grey is T1. T1 is always laying down 0.8mm to the left side.

X stepper set screws are tight, belts are not slipping from the CNC belt clips. No loose screws that I can find.

Really at a loss. I see Helge Keck is no longer here, but I sure hope someone can assist. IDEX is the entire reason I bought and built this machine.

DC Endstop output:

[dual_carriage]

position_max: 459.560

position_endstop: 459.560

[gcode_macro RatOS]

variable_bed_margin_x: [59.800, 59.560]

[gcode_macro _VAOC]

variable_expected_camera_x_position: 163.126

variable_expected_camera_y_position: 429.744

[gcode_macro T0]

variable_parking_position: -57.800

[gcode_macro T1]

variable_parking_position: 457.560

[gcode_macro _LED_START_PRINTING]

gcode:

Note that I left in the prior values for the DC Endpoint, commented out in printer.cfg, for reference. Parts printed identically.

Any assistance would be welcome! And thanks in advance.

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)