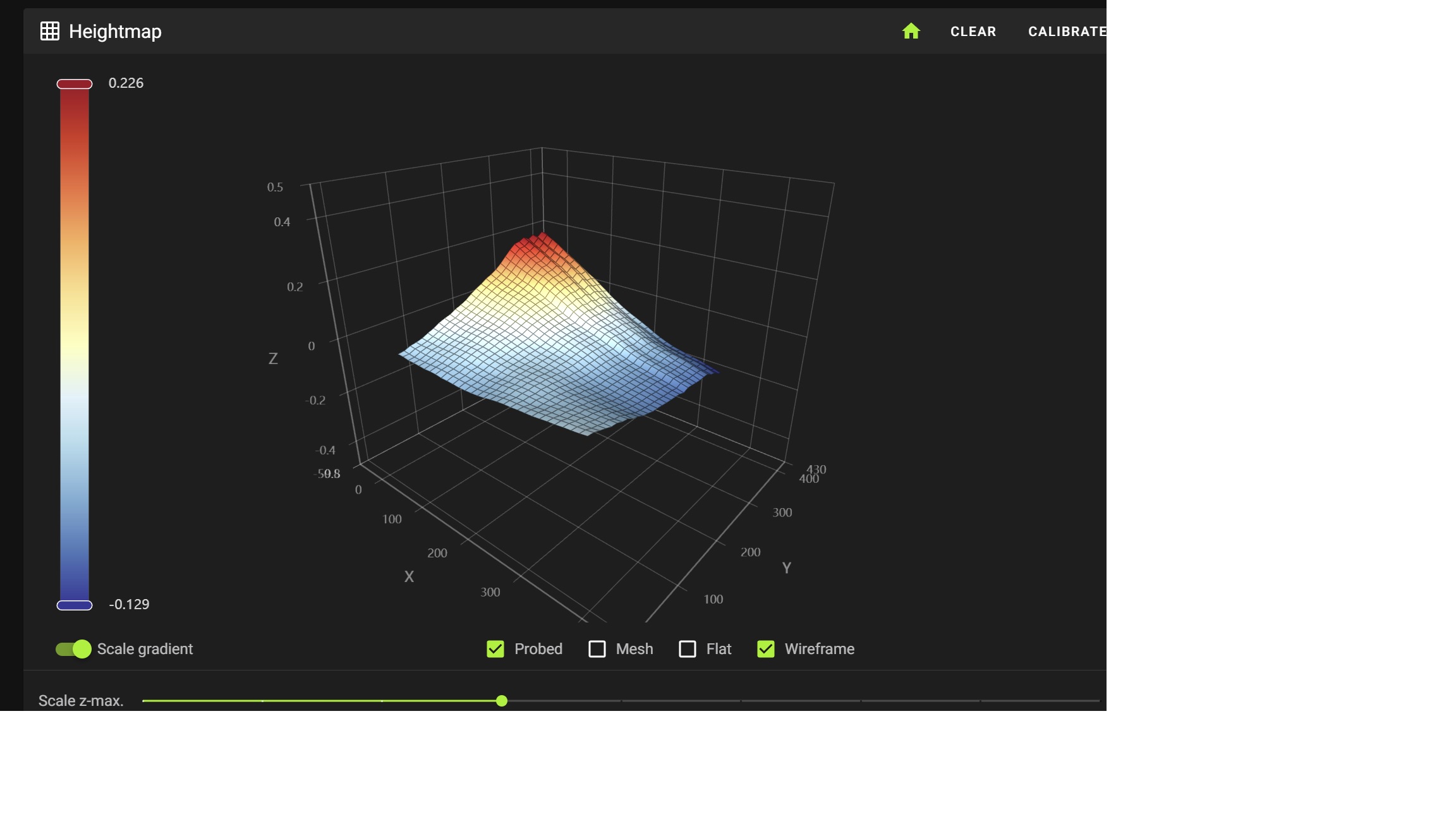

Vcore 4 Hybrid 400 Comissioning bed mesh

So, this is my first try after comissioning, the D corner seems to be a lot higher so I am guessing I need to fix this?

I am reading the guide but I cannot wrap my head around how to adjust it, I don't understand what I need to loosen and hit slightly?

I am reading the guide but I cannot wrap my head around how to adjust it, I don't understand what I need to loosen and hit slightly?

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)