VC4 500 IDEX - Need help for bed mesh during commissioning

✅Solved bed mesh

bed mesh

bed mesh

bed meshHey guys,

I have finished the mechanical and electronics build of my VC4 500mm IXED machine recently and started to get into commissioning in order to start printing asap.

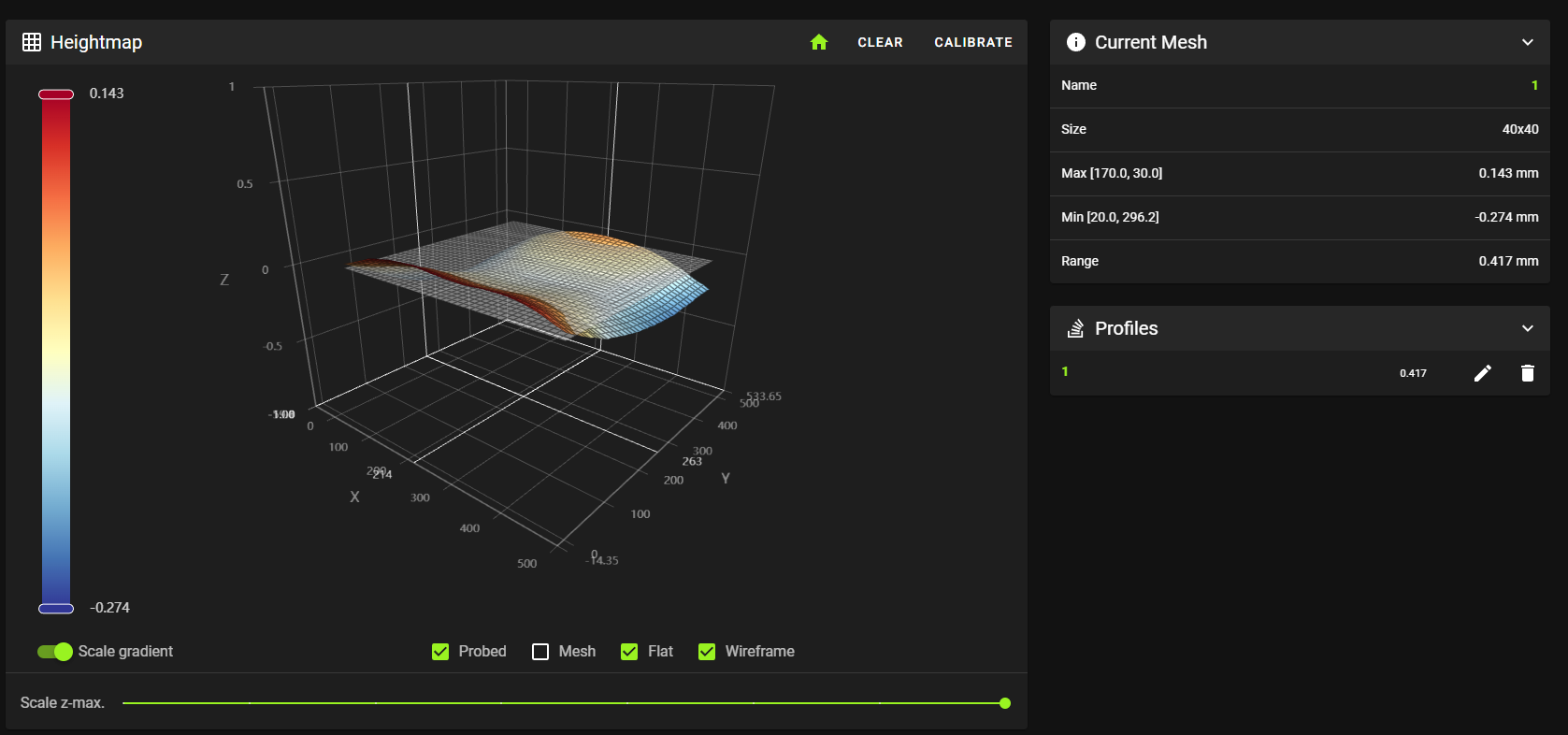

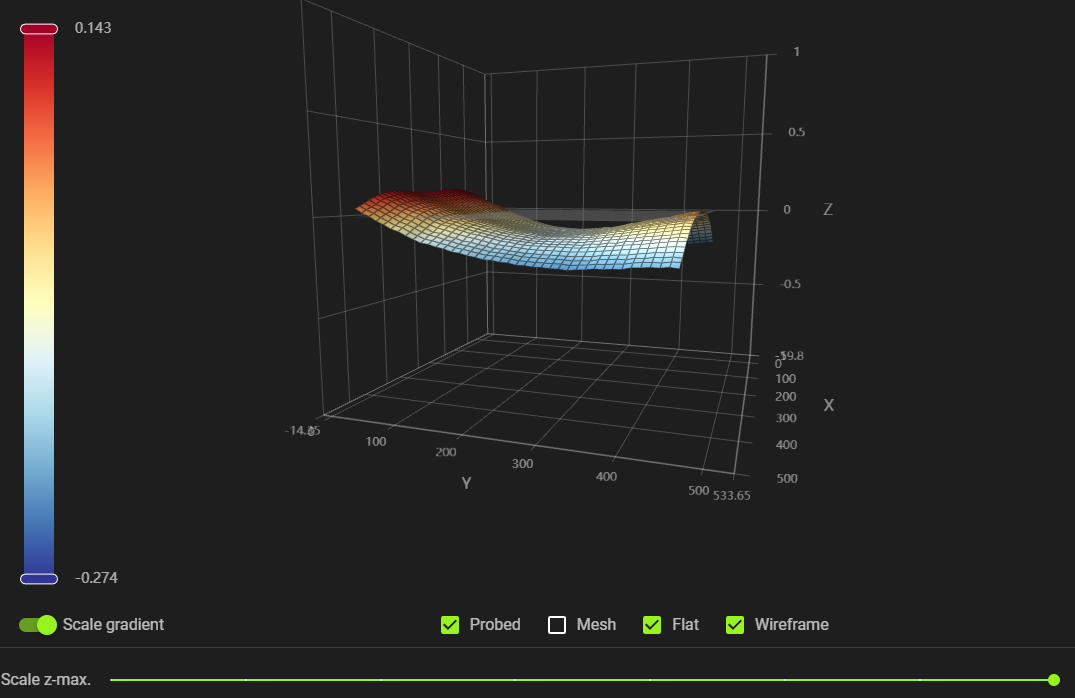

Unfortunately, I've been dealing with some struggle with bed mesh and I can't get better results than this. My C and D points are as low as they can be without forcing too much on machine's structure. I did my best to make put them at the same level watching at the mesh. I still have this kind of taco shape that makes me think that my X and Y got some bending issues.

At the end of the day, this still represents a .4mm difference within 500x500, but I really don't know if this can be handled easily or not with klipper + beacon later on, knowing that this is based on the aluminum plate and not PEI plate which can also lead to some deviations probably.

I'm quite lost tbh and do not know what to do at this point as the guide is focusing more on twisted/tilted issues.

Do you guys suggest putting more effort into this to get better bed mesh? If so, would you have any tips on how to counter that taco shape?

Otherwise, if you think this is good enough, I guess I can go through the rest of the guide and then start printing first layers to see what it can do.

Thank you very much for your help

Eddy

I have finished the mechanical and electronics build of my VC4 500mm IXED machine recently and started to get into commissioning in order to start printing asap.

Unfortunately, I've been dealing with some struggle with bed mesh and I can't get better results than this. My C and D points are as low as they can be without forcing too much on machine's structure. I did my best to make put them at the same level watching at the mesh. I still have this kind of taco shape that makes me think that my X and Y got some bending issues.

At the end of the day, this still represents a .4mm difference within 500x500, but I really don't know if this can be handled easily or not with klipper + beacon later on, knowing that this is based on the aluminum plate and not PEI plate which can also lead to some deviations probably.

I'm quite lost tbh and do not know what to do at this point as the guide is focusing more on twisted/tilted issues.

Do you guys suggest putting more effort into this to get better bed mesh? If so, would you have any tips on how to counter that taco shape?

Otherwise, if you think this is good enough, I guess I can go through the rest of the guide and then start printing first layers to see what it can do.

Thank you very much for your help

Eddy

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)