Possible Mechanical Issue or Binding

I've tightened my belts up a good bit after using some tea bottles as the weight for GATS (2 grams difference between each other), fixed a small gantry misalignment (roughly 2mm), lubed all X and Y carriages, and tightened down my electrical panel.

I'm a bit unsure as to what else may be in play here. Hopefully it's not a squareness issue.

Any thoughts?

25 Replies

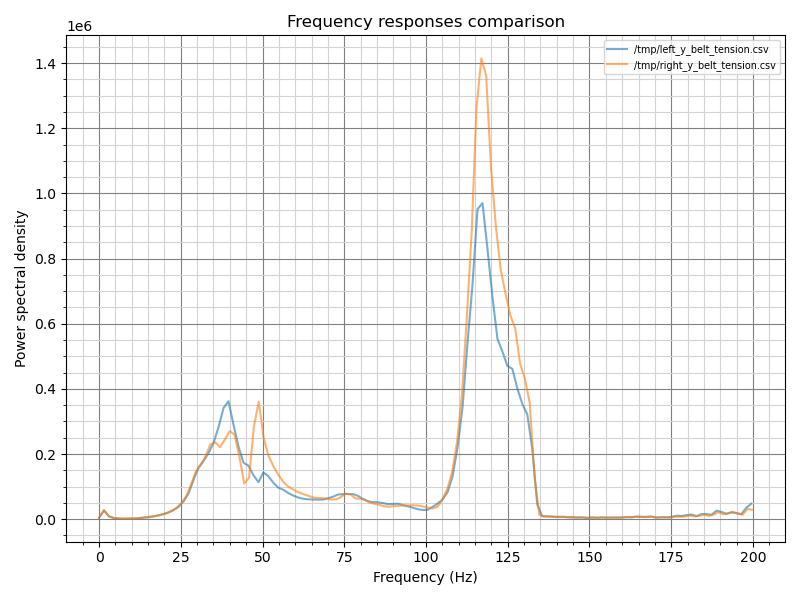

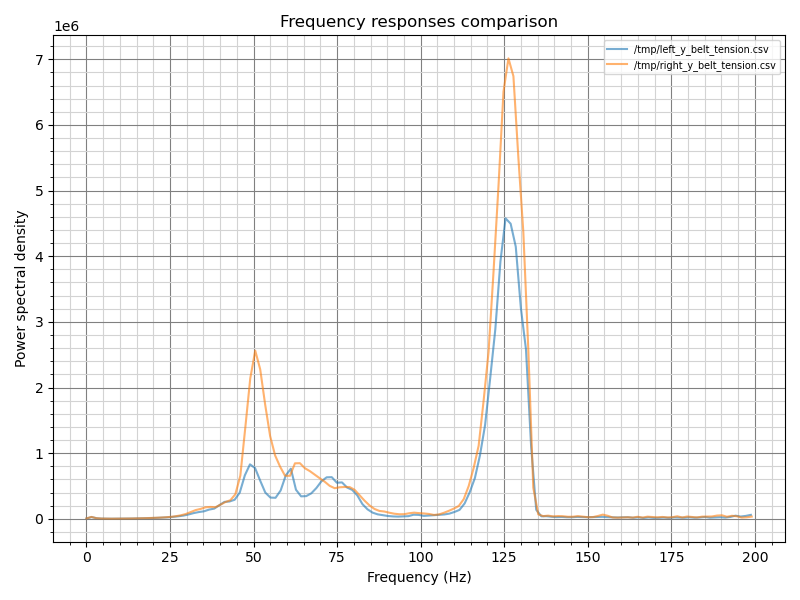

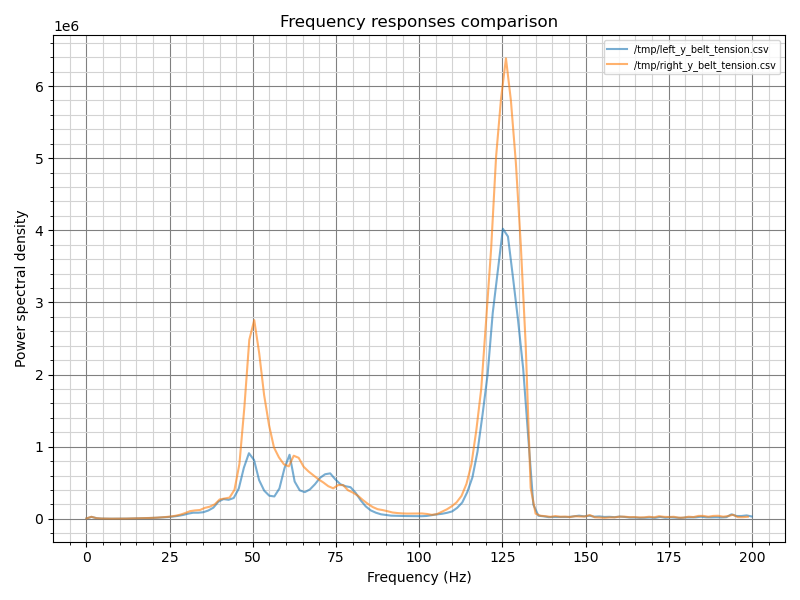

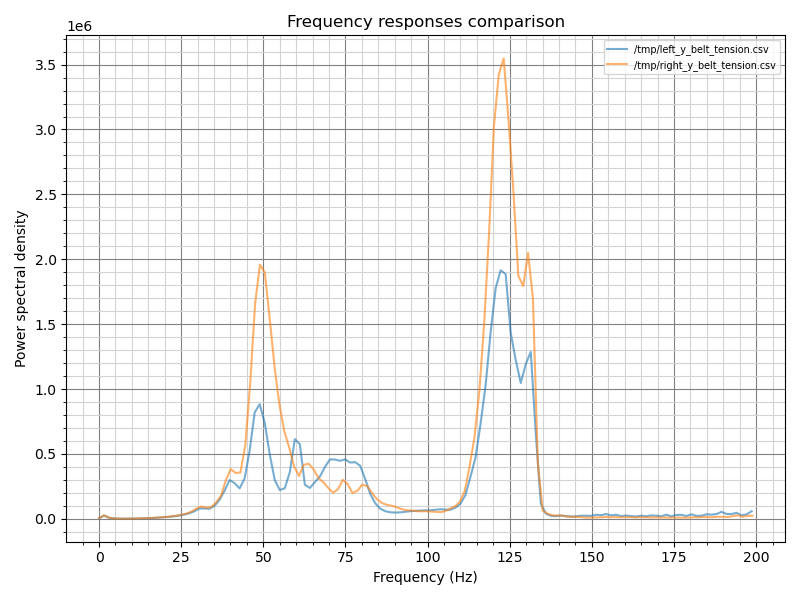

to me, it seems like its been getting worse the more i play with it since i no longer have the low freq bump on the left side, whereas before, they were just misaligned a bit.

the machine does physically vibrate a bit at throughout the process but moreso at the 30-40hz range which does explain a bit of the graph's teeth

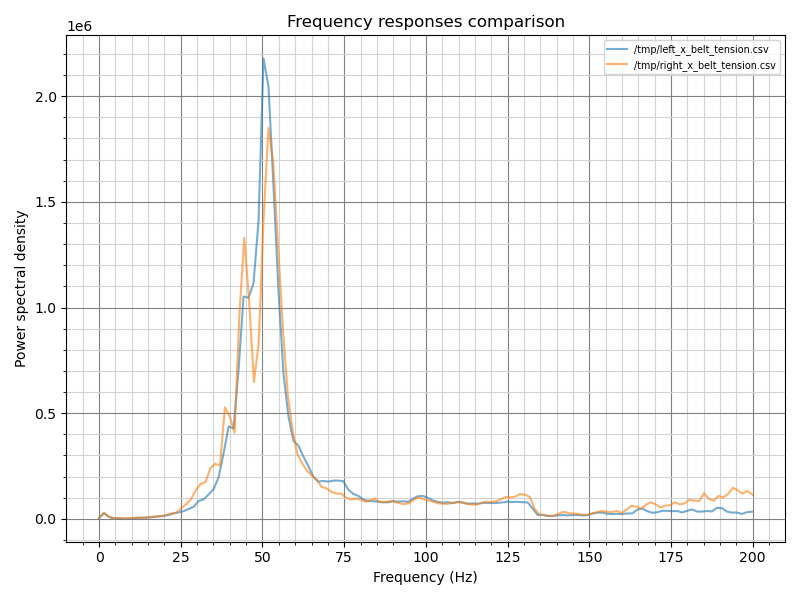

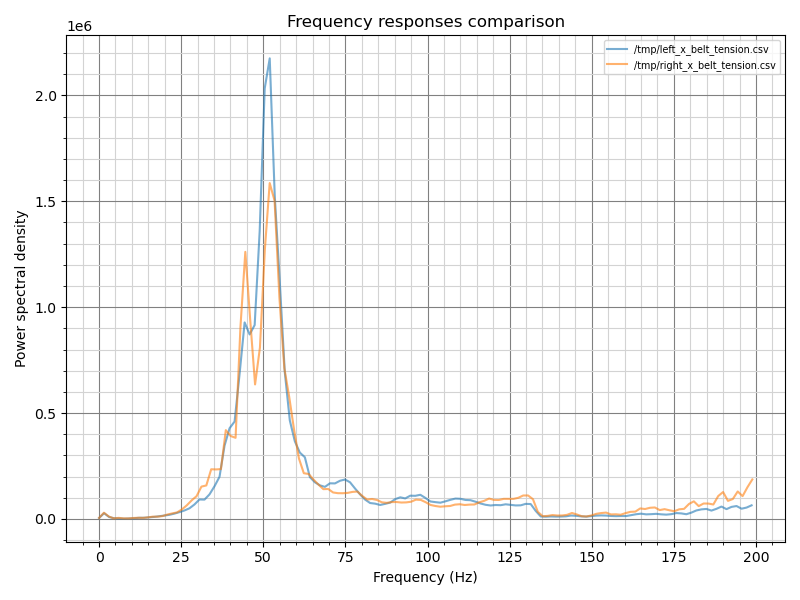

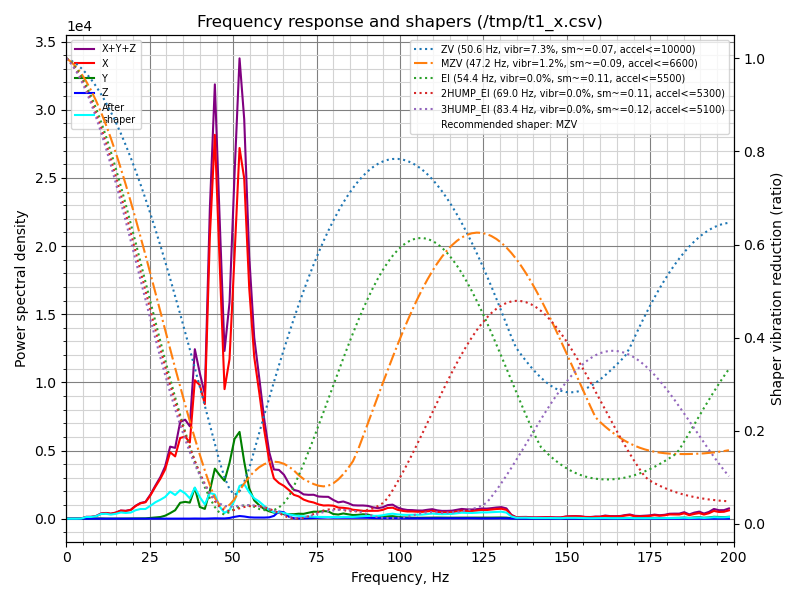

here's my X graph. it seems like there's an small-medium issue on the right belt because of how the orange line is peaking so much?

@Martin Hanbury maybe you have some thoughts on what may be going wrong here? ive tightened down the gantry and toolhead screw and it seemed to rattle less but the right Y belt was reallly shaking

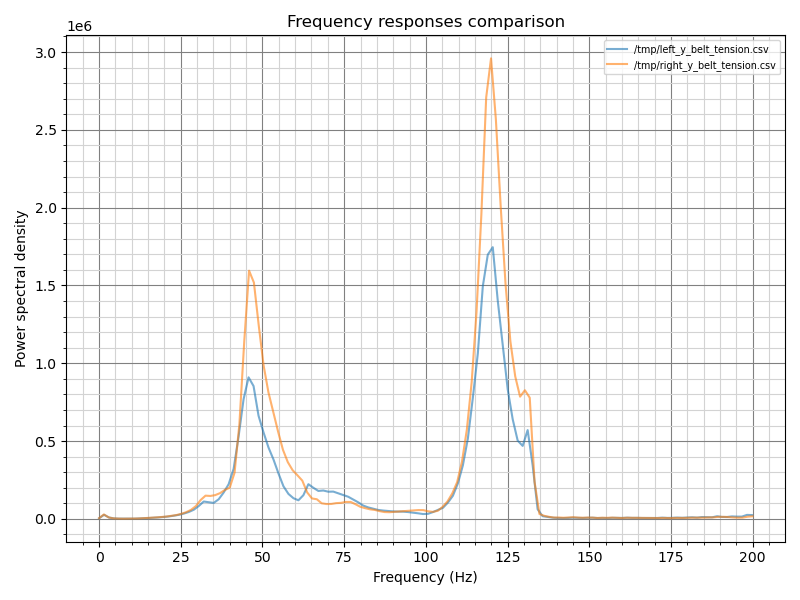

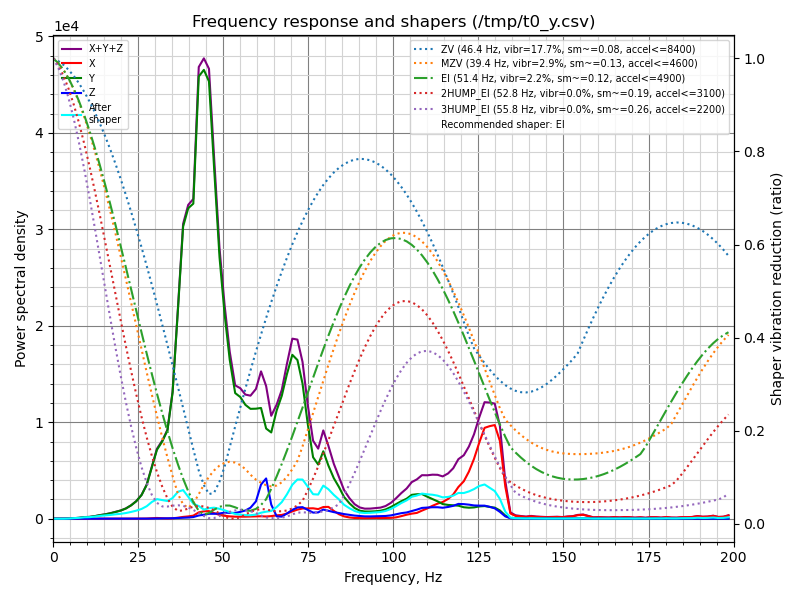

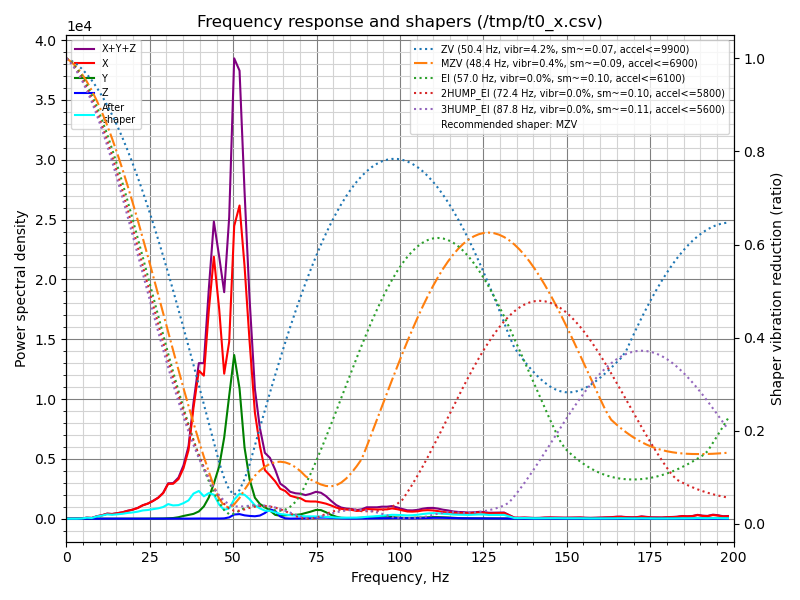

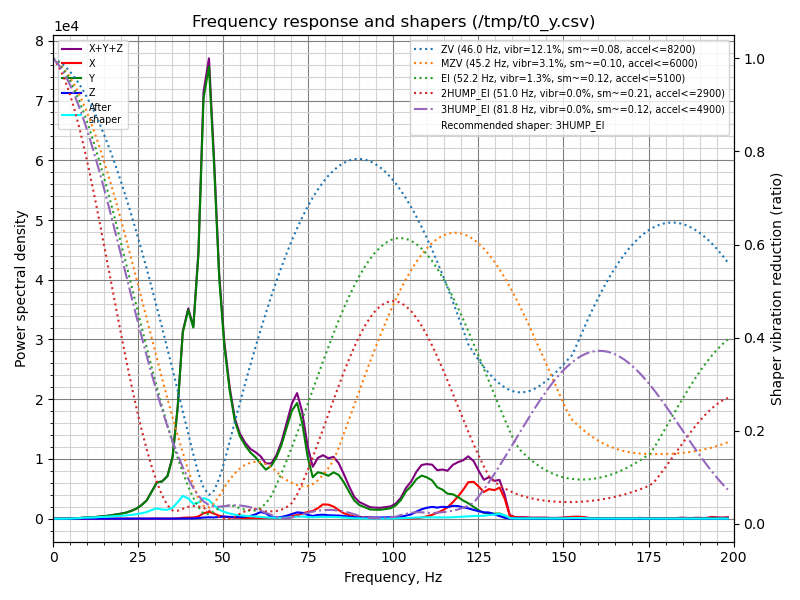

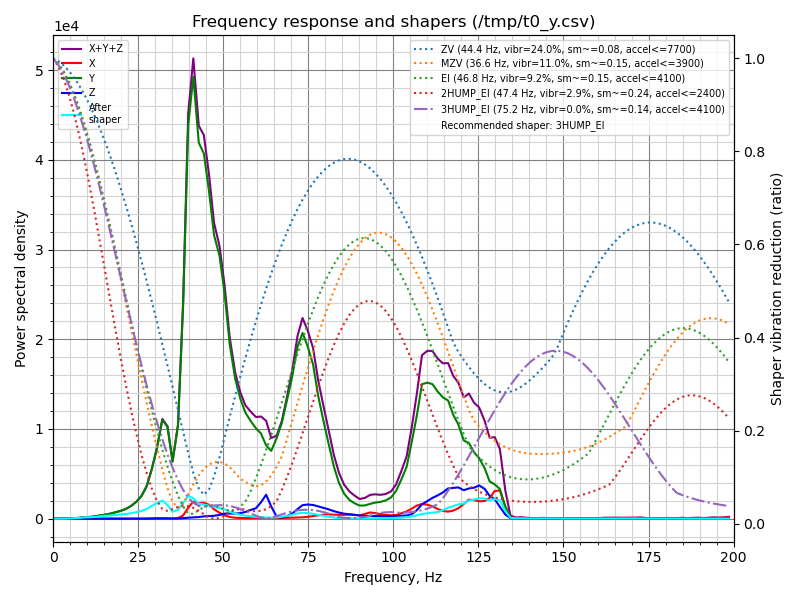

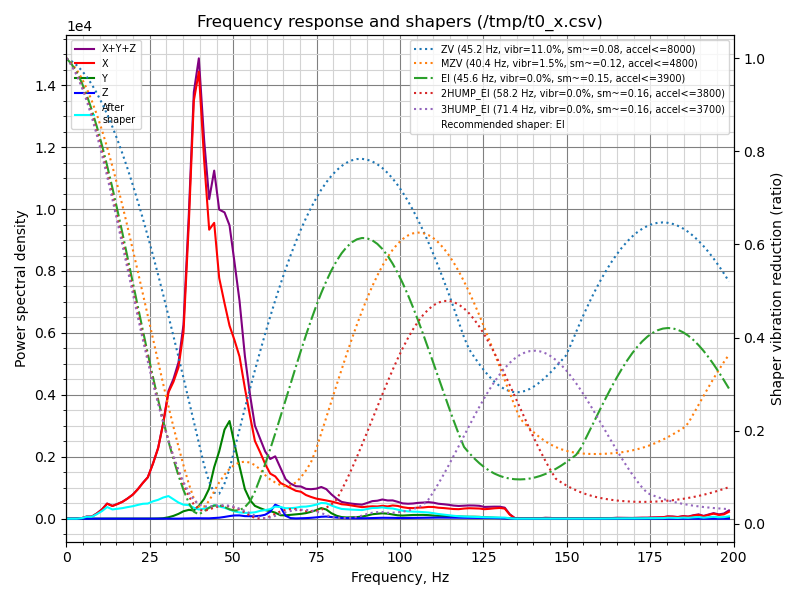

T0:

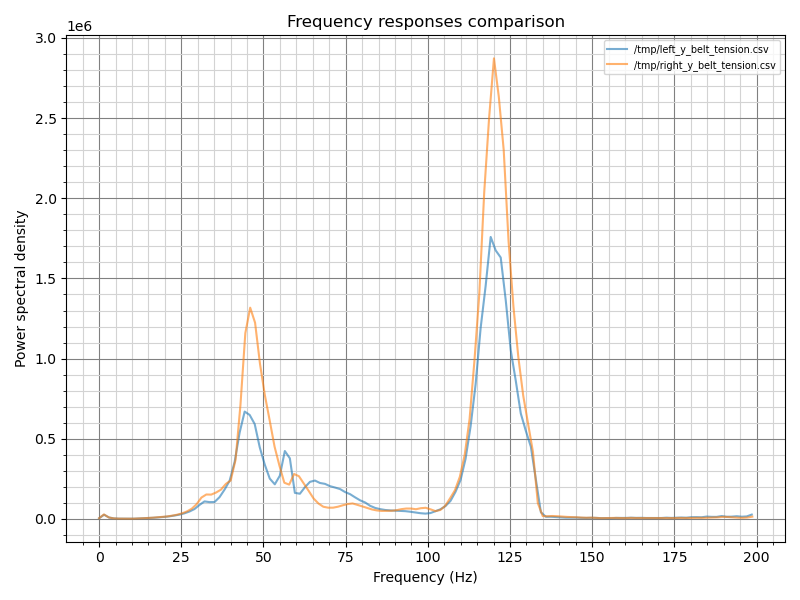

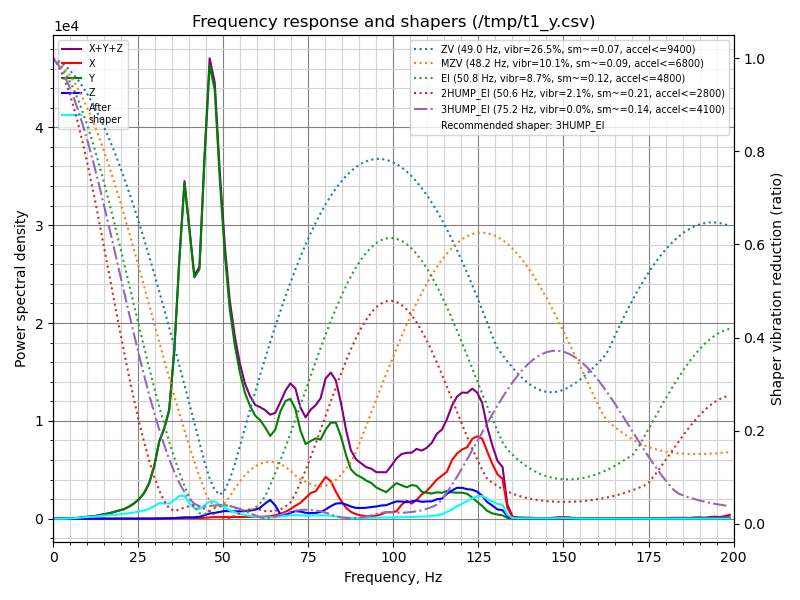

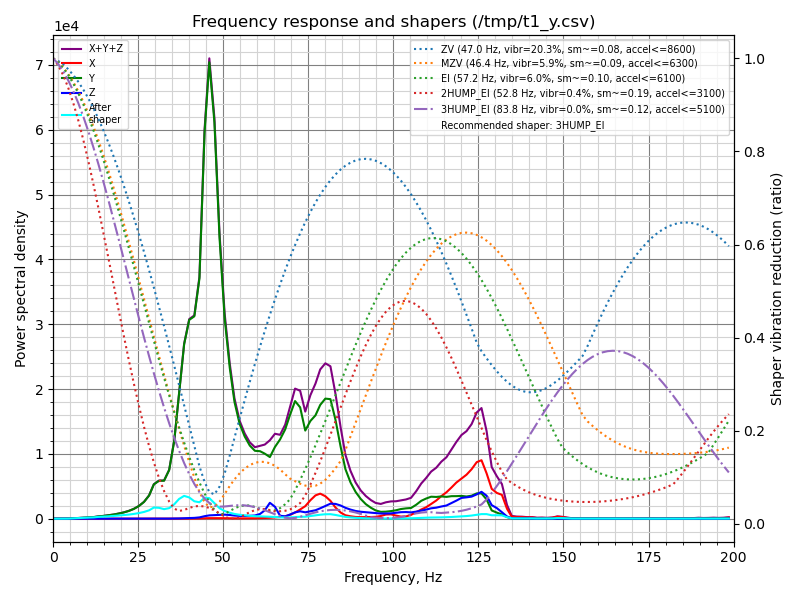

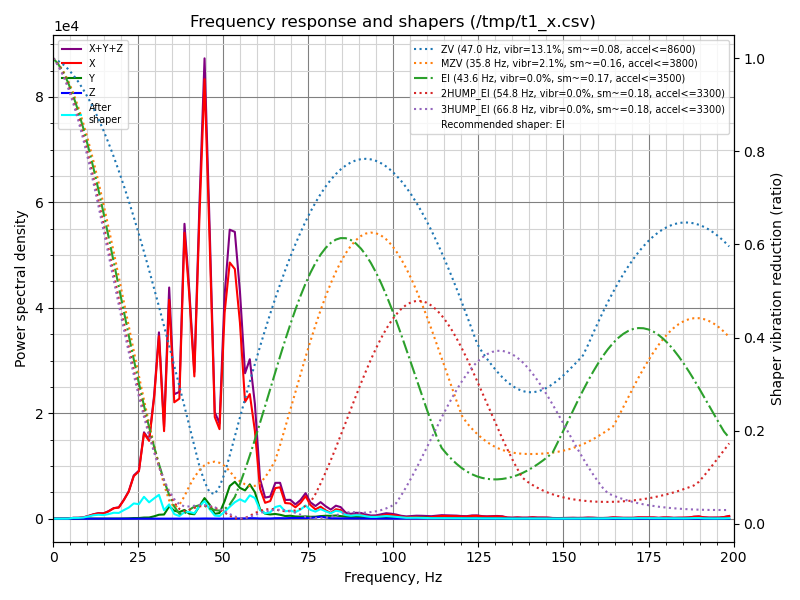

T1

I'd say belt tension related.

fully swapped out the belts and found a couple of semi-loose screws on the motor mounts. re-did GATs and now at least only the T1 head has the 1-2mm Y movement, the T0 head did not.

for the Y test, its still rattling like its on a shake tower at 40-50 hertz though so unless it has to do with my uneaven floor, im at a good loss for what to do next

I wouldnt bother doing the belt tension graphs on an IDEX machine, they dont work properly in Hybrid configuration

oh! so maybe ive been spending hours trying to debug this for no reason?

Well potentially not given you can hear the vibrations, but I would just run shaper graphs and tune them. Tune belts to frequency or weight (GATS) and just run input shapers, dont bother with the belt tension graphs

ok so i did the GATS on the Y belts tonight given the vibrations happen on that axis significantly. i just found out my electronics cover plate is part of the vibrations but something nearby T1 is still rattling too. im probably going to need to open that back up and ensure everything is tight. hopefully its not the wires jostling around since there's still some slack on them in there except the AC lines, which i dont have room to really secure to the case 😐

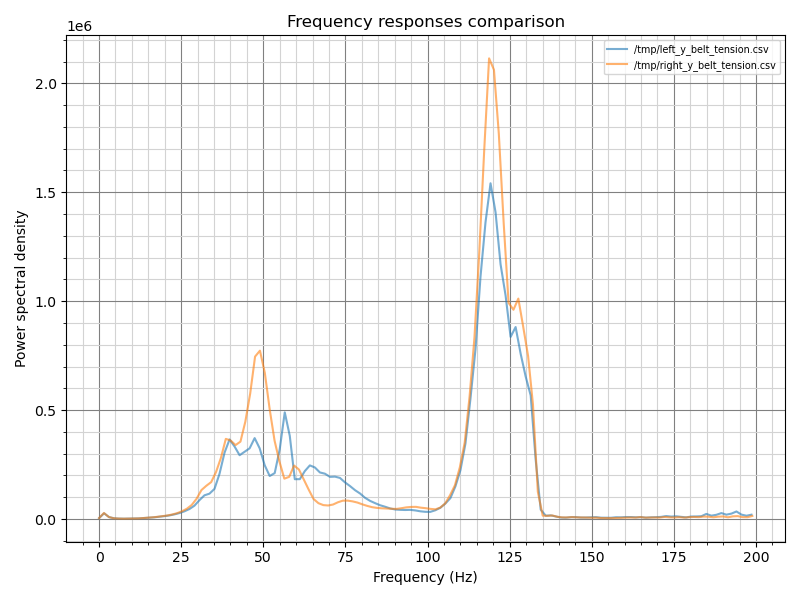

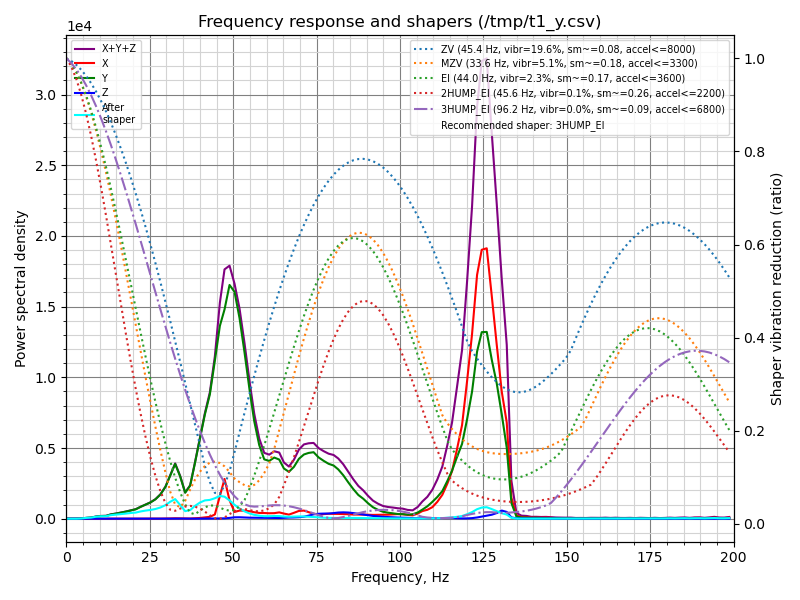

input shaper from a few minutes ago

Yeh this really isn't that bad, especially if this is a fresh build and you're in the early stages of commissioning. You're quite close, find and eliminate the mechanical vibrations (I put foam on EVERYTHING on the enclosure, including the electronics cover), little bit more belt tuning and you'll be just about there

Honestly, I'd probably just do some printing before you spend too much energy on it as well, because everything is going to change after it has settled and worn in a bit

im actually quite surprised at how close the green and purple matched this time. I also was thinking about that too; focusing too much on near perfect mechanics when the guide warns against that. ill see if i can leave work a tad early tomorrow, do GATS on the X, rerun shapers to compare it to today and try a benchy

unless the X isnt too bad. im of course going off no experience and only comparing it to other graphs people have posted, but they're env is very different than mine ofc

There's no point trying to tune X belts after you've tuned Y belts either, you won't get reliable results because the Y belts influence the X belts.

You need to tune X belts first with the Y belts completely disconnected (just unbolt the Y belt clamps from the carriages), then once X belts are finalised you attach the Y belts and tune them

gotcha so ive been focusing on wrong axis first then

@samus129 since you've offered some assistance with another thread having issues with Y, do you mind looking at these from today when you get a chance?

and now that ive finally gotten my realtime analysis page working, there's a real vibration issue on the X after 100hz

im kind of working if i need to break down the entire gantry to find this gigantic rattle

Something seems wrong with this belt vibration too. I redid GATS with a heavier bucket filled with golf balls and seltzer water cans so it'd have more tension.

T1 is right on the 125 MHz and most people have said it's the ambilicle cord so I would try holding it but where it flops around and see if it goes down

T0 looks to be in the 100 - 135 range but it's also only in Y direction so I would that the EBB42 is loose as the 4 screws would stop X movement but not Y

yeah its kinda weird as to how much belt movement there is compared to T0 despite using GATS to have it be as close as possible on tension. i can double check the screws but i did retighten them a few days ago, i very well may have missed something there though

I wonder if the hot end fan or shroud is loose as well

good callout. ill check that as well when im off this meeting

Oh make sure you got small filament peace in the orbiter

I forgot that in both chats

doh! ive only had it in T0 cause i did validate the extruder functioning to at least feel good the machine can half perform lol

filament loaded into the orbiter and rerunning now

oh wow my grinding on T1 is causing more noise than the actual toolhead frequency changes 😬

i took the x belts off and raised the gantry to the top of the frame to work on it and the toolheads move perfectly smooth so im leaning on it being a belt issue for T1