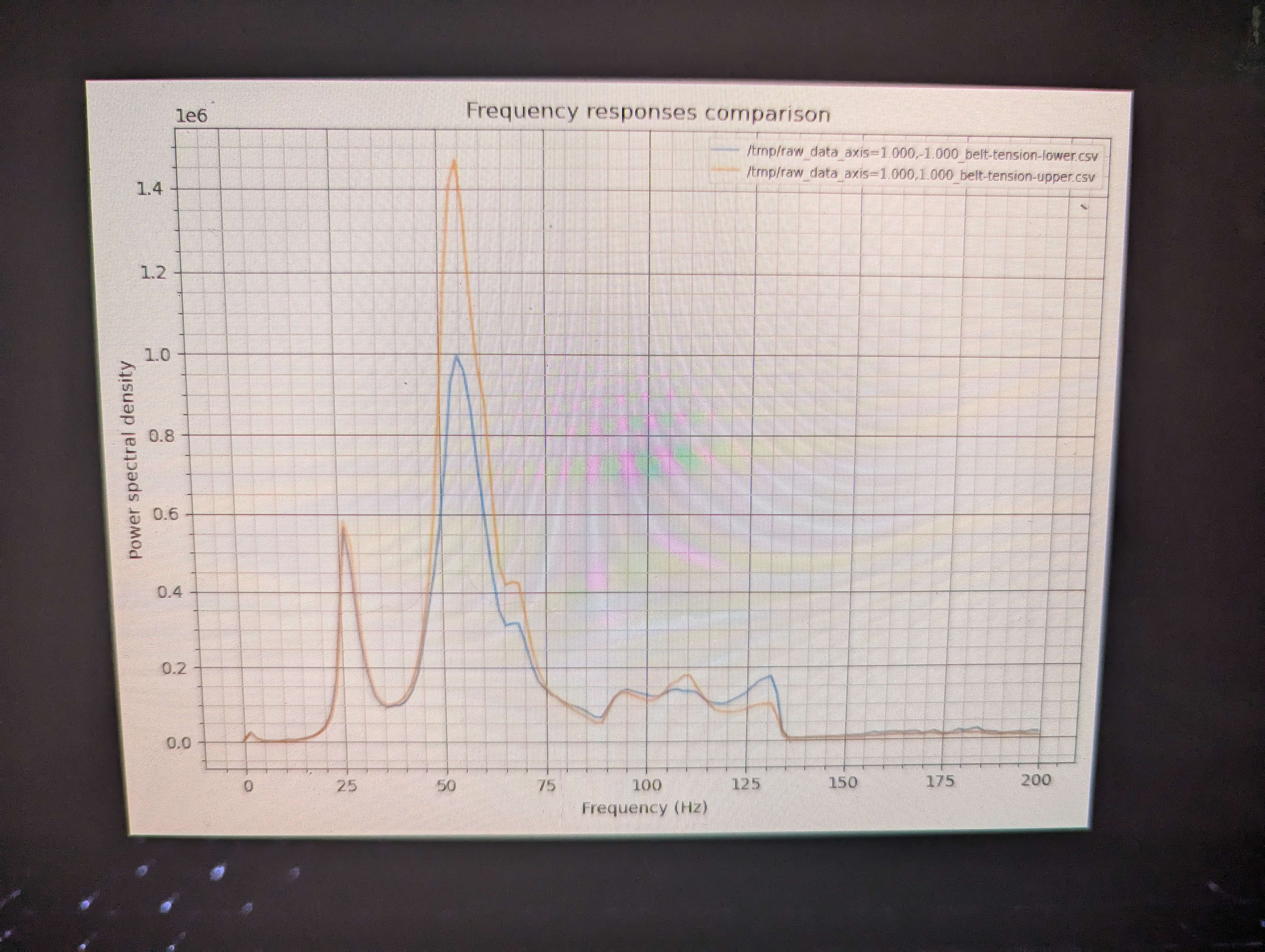

Possible belt rubbing?

Hello all, wondering if this is a belt rubbing (lower amplitude) or something else?

18 Replies

Normally it would be tension and belt length as you have the 2 peaks, the part that has me at odds though is that one is almost spot on but the other isn't though maybe if you lower the yellow we can get a more zoomed in graph 🤔

Lower the tension on the yellow belt you think?

Open to suggestions, I also found it a bit odd lol, I initially thought belt tension but then the tension seemed more related to the freq than the amplitude.

The docs mention amplitude as seemingly rubbing etc which would somewhat relate to this (to a degree) but the amplitude of it with respect to the other examples doesn't seem to fit.

I'll try lowering the yellow belt tension and see what happens

Ya just a little like half turn so it's repeatable amount also sorry for late reply at work

Easy, I'll give it a crack soon, also just running around at the moment haha

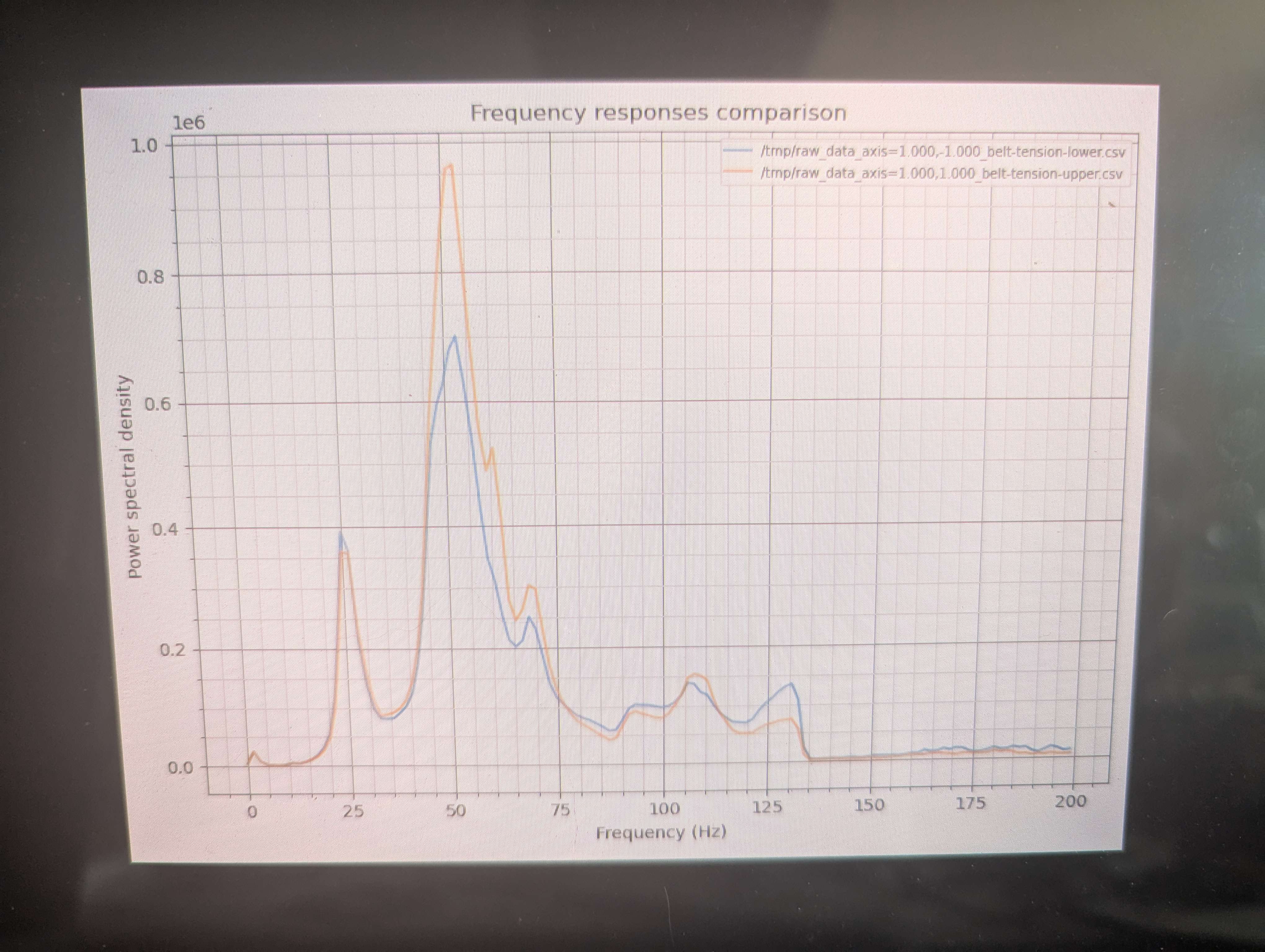

@samus129 lowered the upper belt tension 1/2. (Marked with pencil to be sure)

Going to increase the lower belt tension 1/2 turn

Wow that's super close is all your other calibration done? I would make sure you're still fully squared like both sides of the gantry are touching evenly at the back motor stacks.

Yeah going to go back through now though and check some more things now that the extruder works

Ya better to make sure everything else ok before more tuning belts in case they gotta come off

@samus129 basically everything was loose on the machine, from gantry rails to x, y, z axis parts lol.

Found it as the beacon would never correctly calibrate.

After fixing that, I then relooked at the bed mesh, fixed the frame issues on that and managed to very easily get ~0.249 (with way more to be able to corrected still on that easily)

I'm currently re running the belt tension graphs and I'll have the new results after tweaking up in a bit.

To confirm, it's generally better to have the amplitudes matching, however, it's more important the peaks line up at the correct frequency?

I don't believe one is more important than the other it's more you want 2 clean peaks so that you can make sure the belts are able to move properly. If your going to build IDEX after though that is a whole other thing

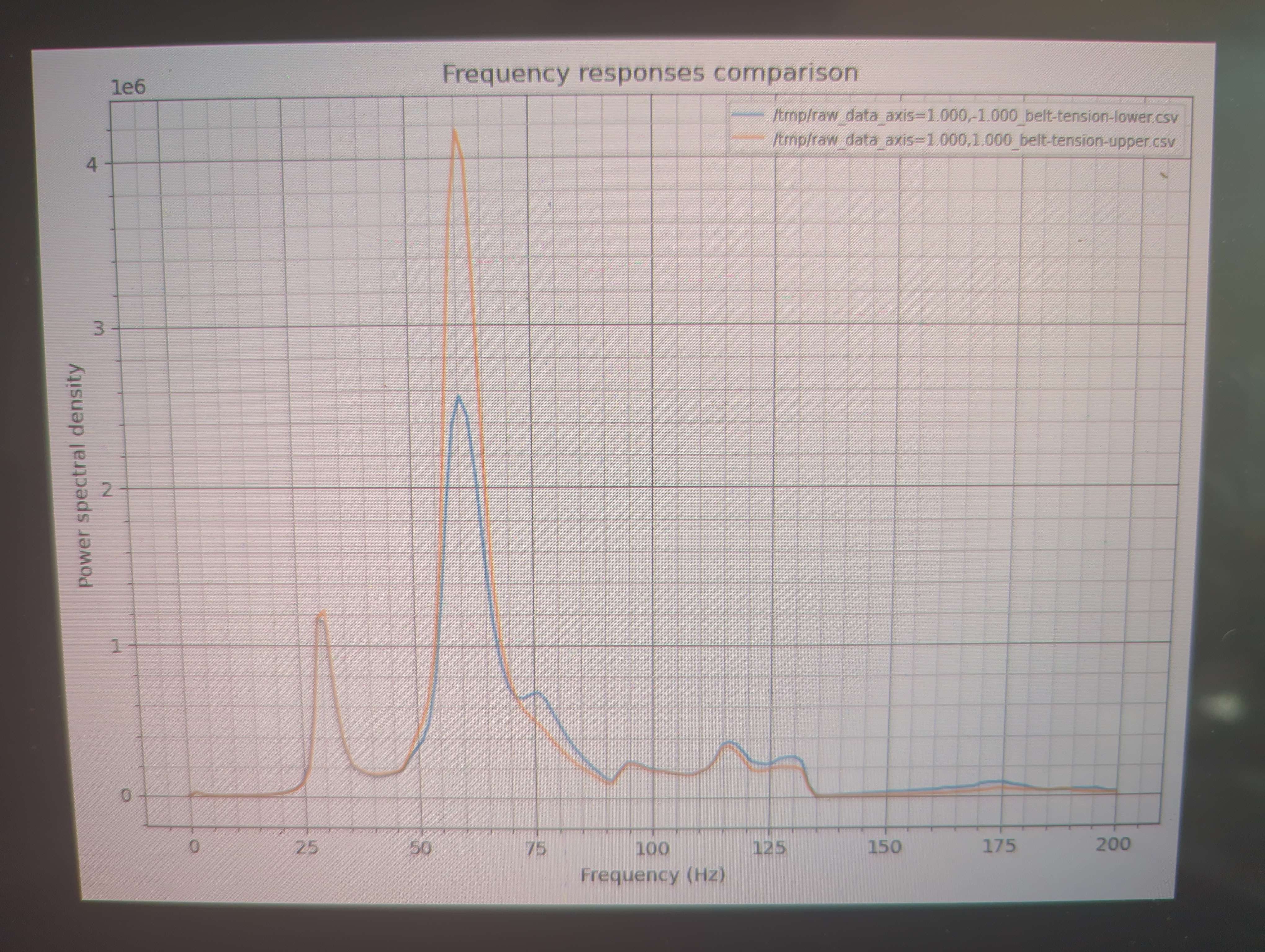

Latest result, clean peaks ish but still the amplitude gap

Gantry twist is minimal as well, touches front and back on both sides

Possible stopper alignment issue on the y rails?

(would cause gantry to appear to contact on both sides but unevenly I guess)

If I lower or raise the belt tension, the tension peaks respond by shifting towards the respective direction

Is it possible the frequency it shifts too on the peak is somewhat cyclic i.e moves between a range on tension force? Which would then mean I could either back off or tighten the respective belts to match, if not, adjusting the belt tension won't really matter as it'll always shift

Correct the end stop trigger stops you from checking front when it's installed

It might but I'm not positive about that sorry. I would say those graphs are good though how does everything else look?

Oh fantastic for sure, consistent bed meshes around the same ranges 200-300, low gantry twist reported from beacon_ratos_calibrate, it passed first time once I fixed everything too.

Only really the tension graphs I was iffy about before installing the hybrid belts

Would you suggest rolling along the. To the hybrid belts if everything else seems grand?

Yep you can move on as they don't need to perfect

Thanks for the support and advice mate!

What I have found is that a gap on the y-axis is usually caused by the belts being different lengths. If you still have enough nerve, remove the belts, lay them next to each other and shorten them to the same length. Or take a paint marker, mark a spot on both belts and set the same length for both belts to the exact tooth.