Initial Z-Tilt is failing. New Build

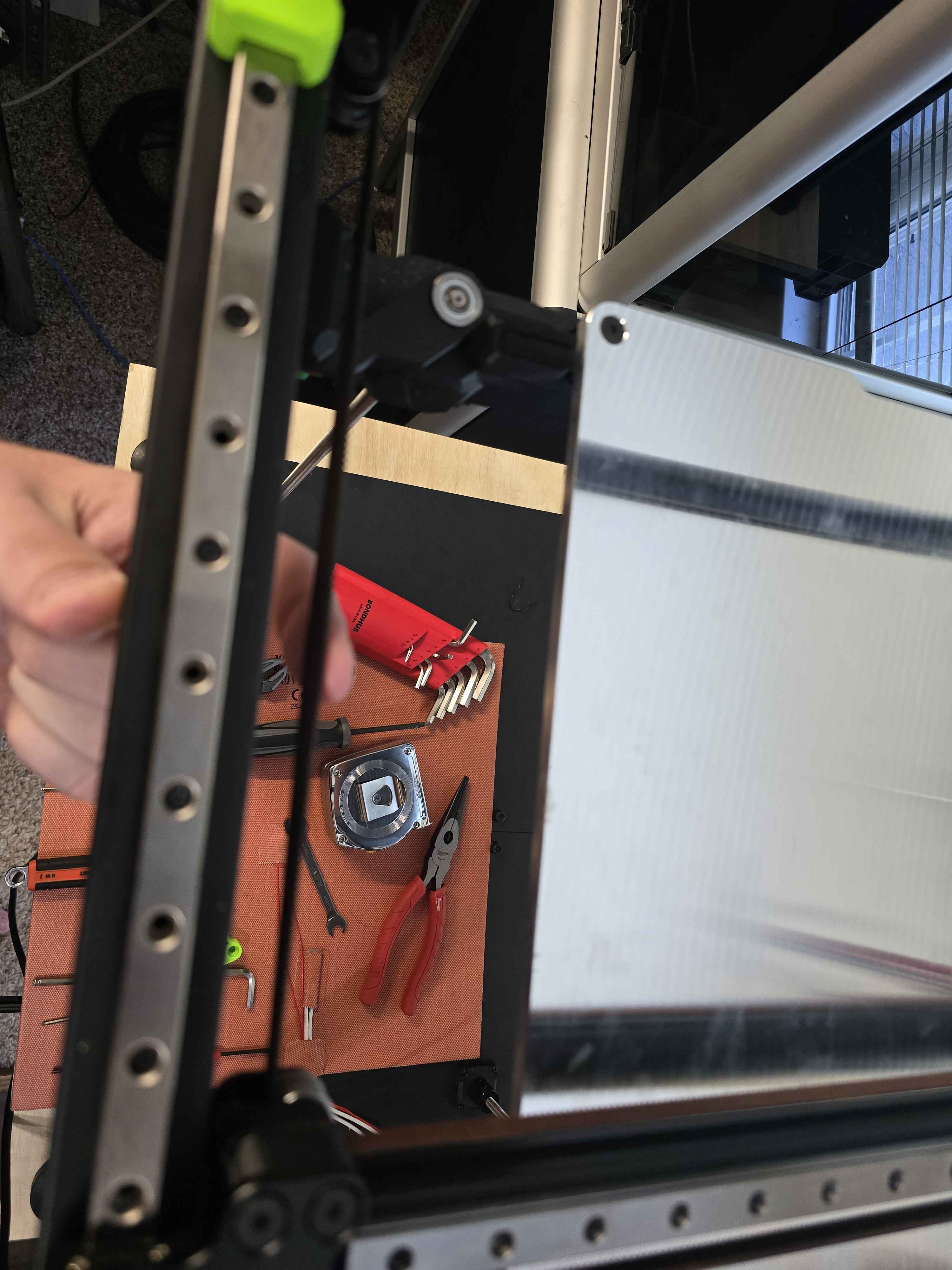

I just got my V-Core 4 400mm Hybrid turned on today and was running through the commisioning guide. I got to the Z-Tilt calibration with no real issues except a bad crimp on one of the X Endstop wires. Everything seems to be fine until I attempt the Z-Tilt.

When I attempt the Z-Tilt it will go to a couple spots then goes to the end of the X rail and I get an error saying "No trigger on probe after full movement."

I have already checked the motor direction and can move the toolhead via the controls in Mainsail without issue.

I reflashed the OS and reupdated everything. All firmware/software is up to date.

I feel it is either a motor configured wrong or software is messed up and causing the motors to move the toolhead the wrong direction.

Any help is appreciated!

28 Replies

So you're able to do a normal homing sequence, right?

Yes. I can home normally. It is just the Z-Tilt that is acting weird.

This is what the Z tilt procedure is doing. This was immediately following a successful home attempt

seems off - how did you get those values?

I just ran through the configurator follwing the commisioning guide. I only edited the files originally to invert the Z motors

yeah, something is off because it should be checking roughly over each pivot point to do the z-tilt

Any idea what? This is my first Core XY printer and first from scratch build

I only have a vcore3 so maybe things are different, but my rotation distance is 2 compared to your 40.

But in general, I have seen people mess up connecting the steppers in the wrong slots and cause all sorts of problems (look at stepper buzz to verify) as well as modifying things they shouldn't have or having corrupt files because they didn't shut down cleanly

So I've checked and rechecked all my motor connections. I reconfigured the system to just the base core XY as I didn't have the hybrid belts hooked up anyways. I can buzz the x and y stepper motors and the correct motors move. I'm pretty sure that I have the motors wired and configured correctly.

The config file says to use 40 for the rotation_distance which makes sense with b the 2gt belts and 20 tooth pulleys.

I got the attached video where in the initial second or 2 it seems like the tool head should be moving but is stuck and then it moves without issue, but the positioning is screwed up this messing up the tilt calibration.

My axis are all aligned and I can easily move the gantry and tool head anywhere if I disable the steppers with M18

My axis are all aligned and I can easily move the gantry and tool head anywhere if I disable the steppers with M18

Try moving the toolhead via the dashboard. Measure how far it goes and make sure it matches up

Moving the gantry/head via the dashboard is aligning properly. I measured X and Y using my calipers and its moving as expected withing +-0.1 mm

Gotcha. That confirms your rotation_distance is accurate then

Did you buzz each z-stepper and confirm z0 is left, z1 is center, z2 is right?

Yes I have buzzed all 5 stepper motors at this point and all are correct

Wait, is the toothed pulley setscrew tightened properly on both pulleys? That might cause your issue, the very high torque at start causing it to slip and then eventually catch and spin.

Yes both set screws on both pulleys are as tight as I can get them. The right one does not have a set screw aligned with the flat, but even after removing the set screws I can't get the pulley to free spin on the shaft so I don't think it is slipping. Attempting to fix the alignment now without disassembling the entire thing.

Got the pulleys aligned with flat and all set screws are nice and tight. I think the issue is being caused by the motors attempt to move at high speed. If I enable the Performance mode, then I can't even get X or Y to home properly. The tool head binds/locks up right after it hits the endstop the second time. If I disable performance mode, then I can home without issue.

how tight are your belts?

They are fairly tight. With the Gantry at roughly the center of Y I can just barely get the belt to touch the extrusion on the side on the front part of the printer. Im researching belt tension more now as I wasn't sure what I was supposed to have those set at.

looser is better, try loosening it some

you really only need it tight enough to not slap the extrusion when running

too much tension can cause the steppers to work harder or cause binding. Might be contributing to why it is slipping when trying to move quickly

I feel like it is a belt tension issue. I loosened both belts ~4 turns of the tension screw and it gets further through the Tilt procedure before failing the same way. I think I have them too loose now but I will keep playing with it.

@blacksmithforlife Thank you for all your help! It was a belt tension issue. I let out a couple more mm of belt from the toolhead and used the tensioners to pull it tight, but not nearly as tight as before and I was able to successfully run the Z Tilt!

Glad I could help

Looks like I might have spoke too soon. I was able to run the z tilt calibration but when I put the system into performance mode I am no longer able to home x or y unless I show the speed down to like 25%.

If I take the belts off the gantry I can move the tool head around with no resistance at all. The piano wire that supports the cables is enough to push the head around. So I know the gantry is good and square.

After I put the belts on I make sure to check for twist repeatedly as I tighten the belts. I have tried to tighten the belts using the Pano Tuner app and I believe I have them set correctly. I am getting approximately 120hz from the belt between the tensioner and joiner.

Whenever I home X or Y after it hits the endstop the second time it only moves the head or gantry about 1/2 inch and the motors wine pretty loud

If you re-loosen the belts like what helped earlier is it able to home?

I loosened the belts as much as I could and kept stepping up the tension about 1/2 turn and I cannot get it to home at more than 35% speed. Occasionally I can get X to home up to about 60% but it's not reliable and I haven't gotten Y to home above 35 at all

After I put the belts on I make sure to check for twist repeatedly as I tighten the belts. I have tried to tighten the belts using the Pano Tuner app and I believe I have them set correctly. I am getting approximately 120hz from the belt between the tensioner and joiner.don't do this - tighten just enough to get the slack out, then run a homing and if the belts are slapping the frame then tighten a little more. People often way over tighten the belts. There's a reason why there are macros for getting the belt tension correct

Just an FYI I seem to have finally figured out the issue on this. I tried my belt tensions up and down the spectrum but could never get anything to function the way it was supposed to. The issue appears to be the BTT Kraken main board I was running. I ended up ordering an Octopus 1.1 as a last ditch effort and first attempt without changing any of my belt tensions or anything other than running the configurator to swap the board, I was able to run it in performance mode and even get a full print done. Still needs tuning but I'm significantly better off and its at least functional now.

Thank you all again for all the help you have provided!

Sorry for the obnoxious and confusing board issue, but glad you figured it out. Best of luck in your future printing!