Calibration cube tuning

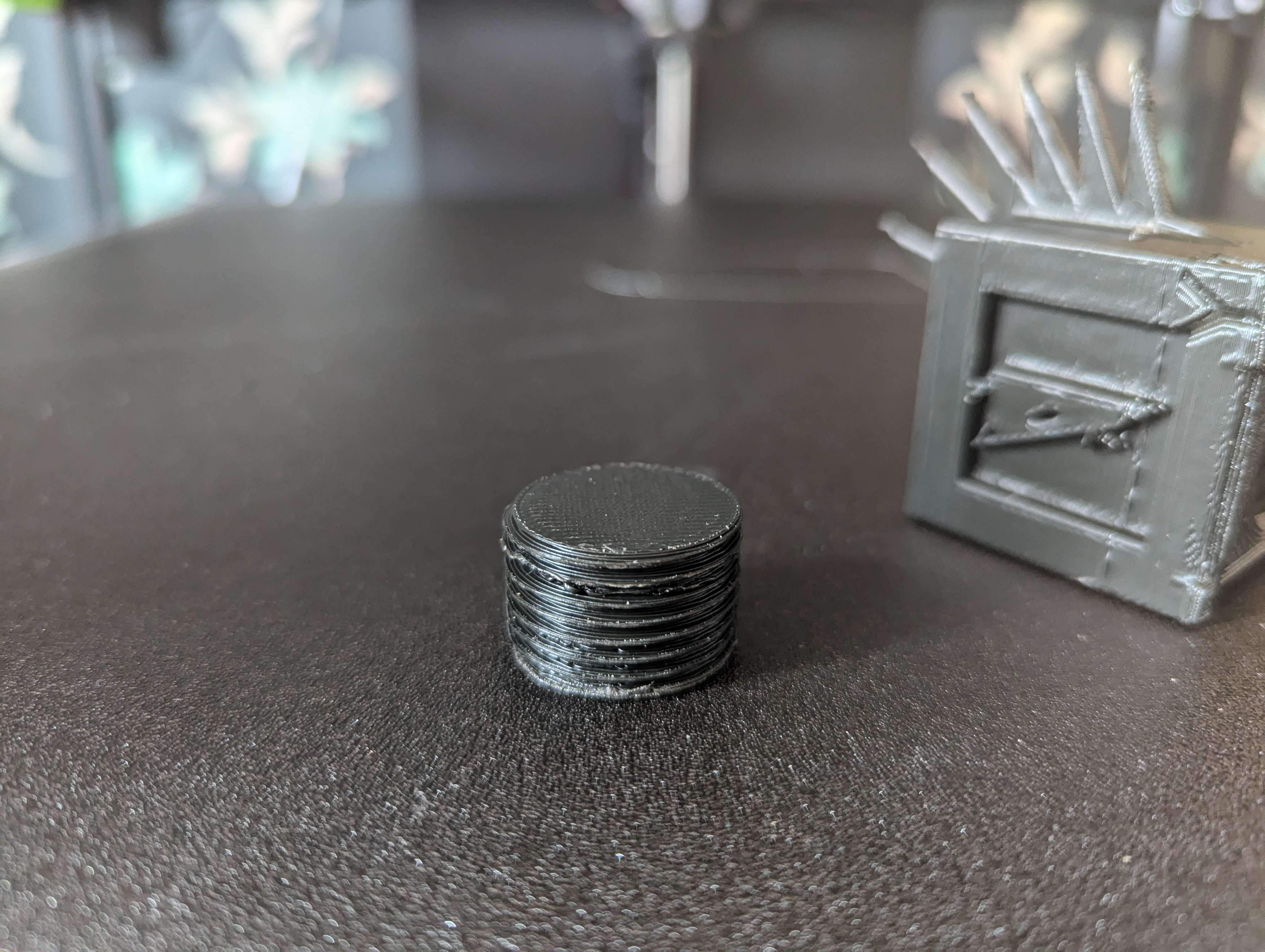

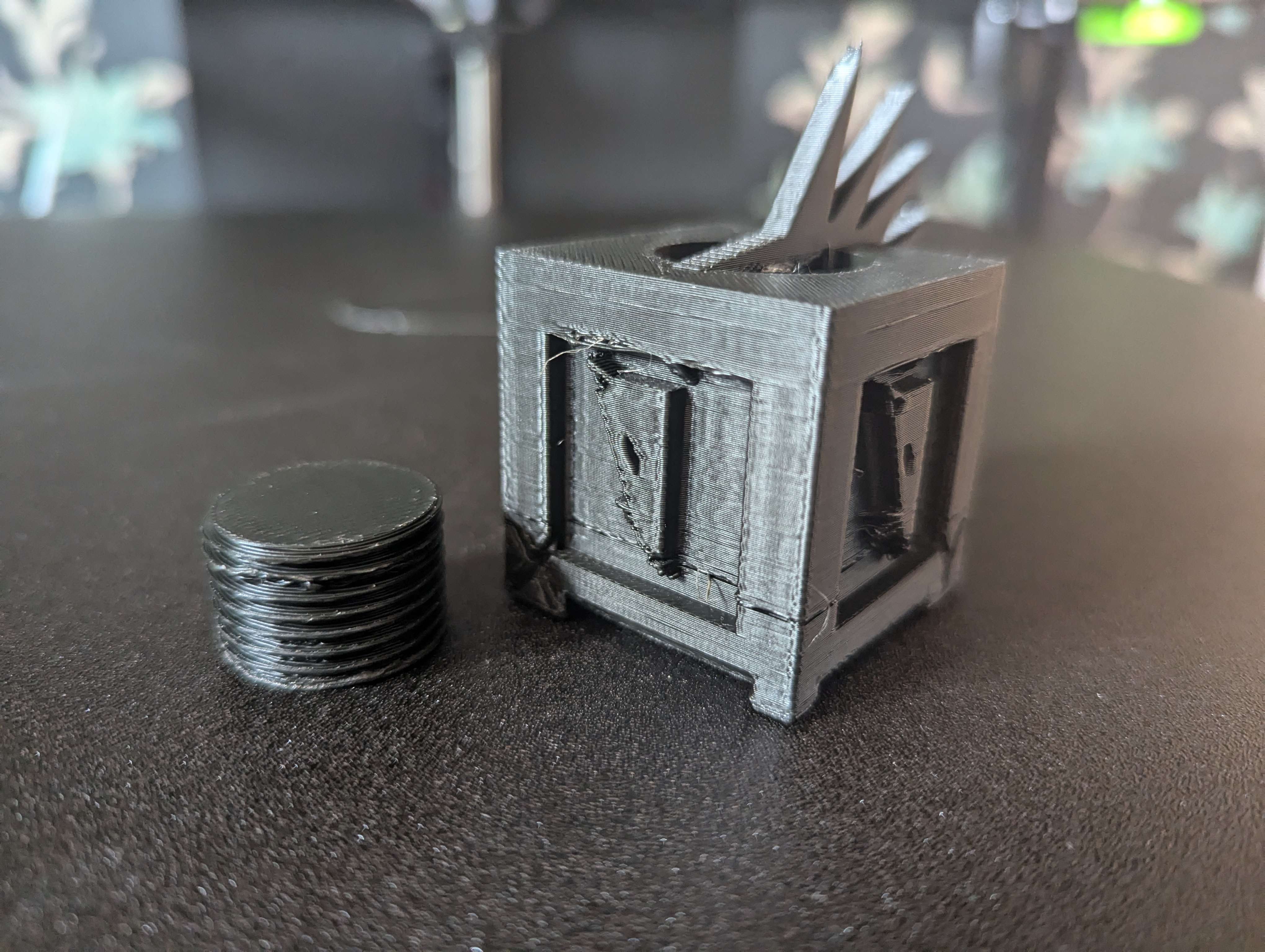

Just finished printing the calibration cube.

I'm amazed at the results, however I'd like to know what and how I should tune the printer/slicer now based on the cube.

The threaded bolt screws in a couple turns, however is quite stiff so immediately I think Xy compensation would be required.

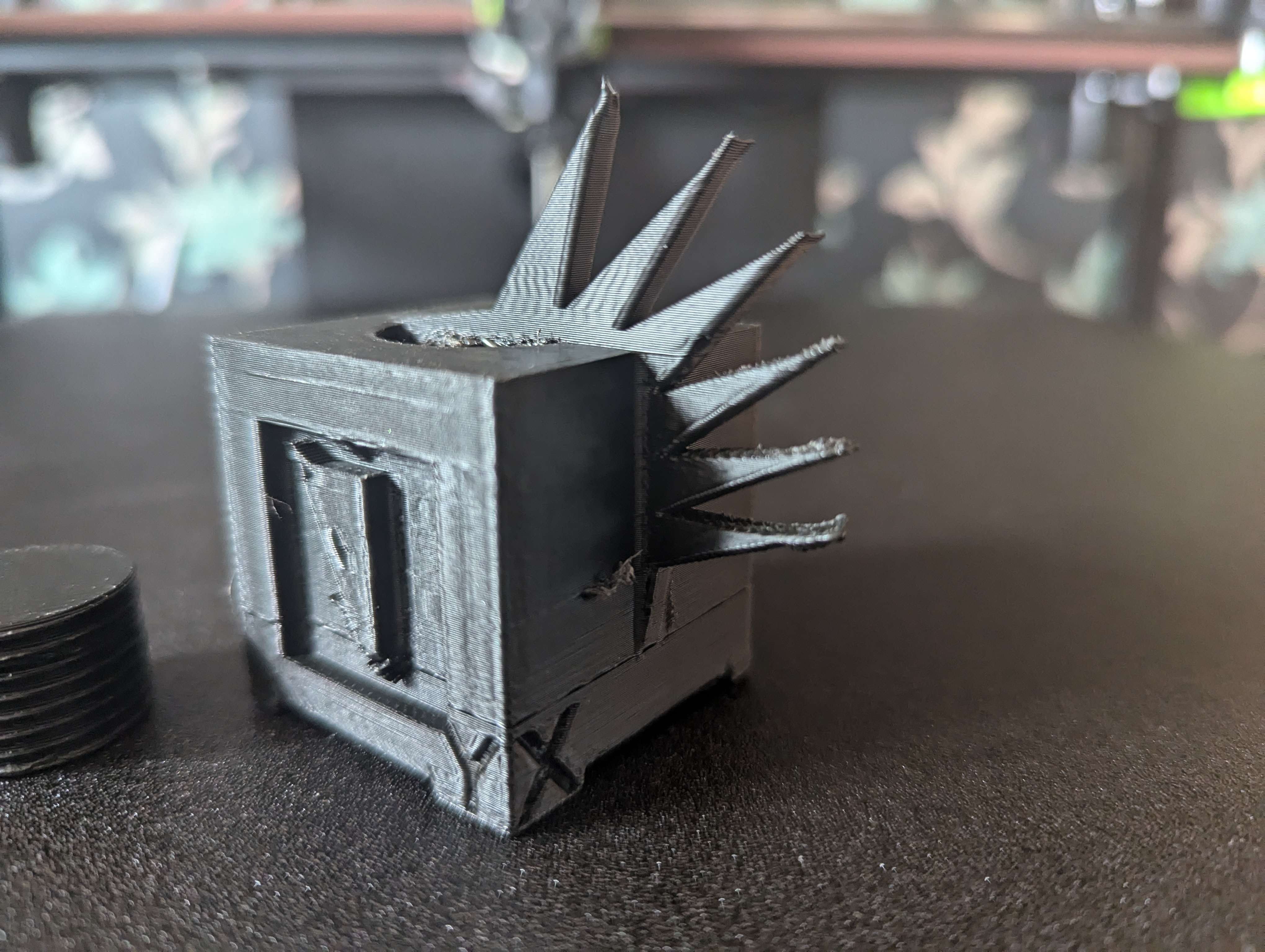

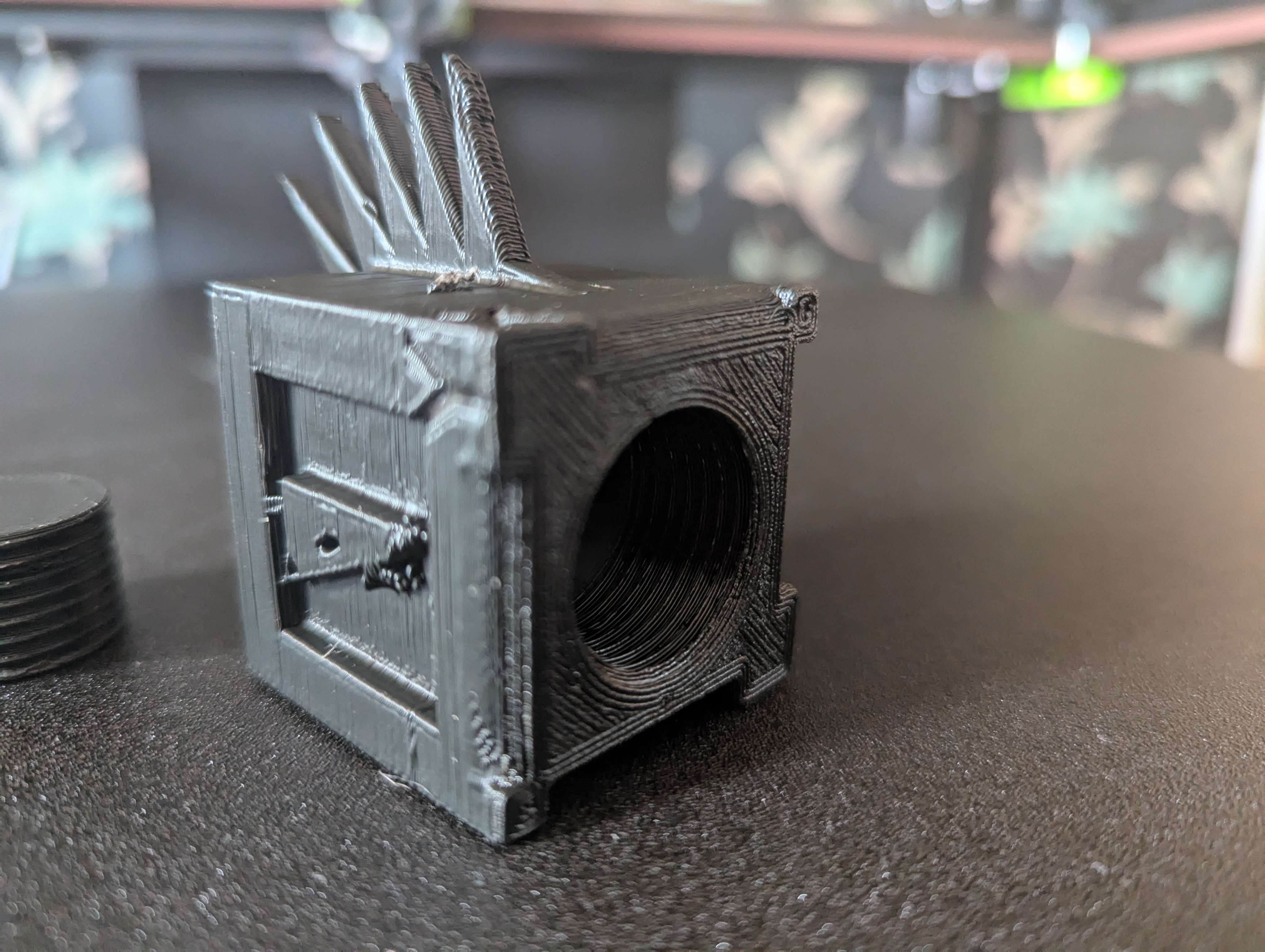

There's some ugly overhangs as well, would fan speed or print speed fix that issue, or is it more temperature related?

I'm amazed at the results, however I'd like to know what and how I should tune the printer/slicer now based on the cube.

The threaded bolt screws in a couple turns, however is quite stiff so immediately I think Xy compensation would be required.

There's some ugly overhangs as well, would fan speed or print speed fix that issue, or is it more temperature related?

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)