Can't get printer to print more objects at once

Hi everyone,

I’m trying to print with my newly built VC4-400 with the hybrid upgrade, but I can’t get it to work as expected. The first layer on the first object looks fine, but each following object turns out worse and worse.

I’ve attached photos:

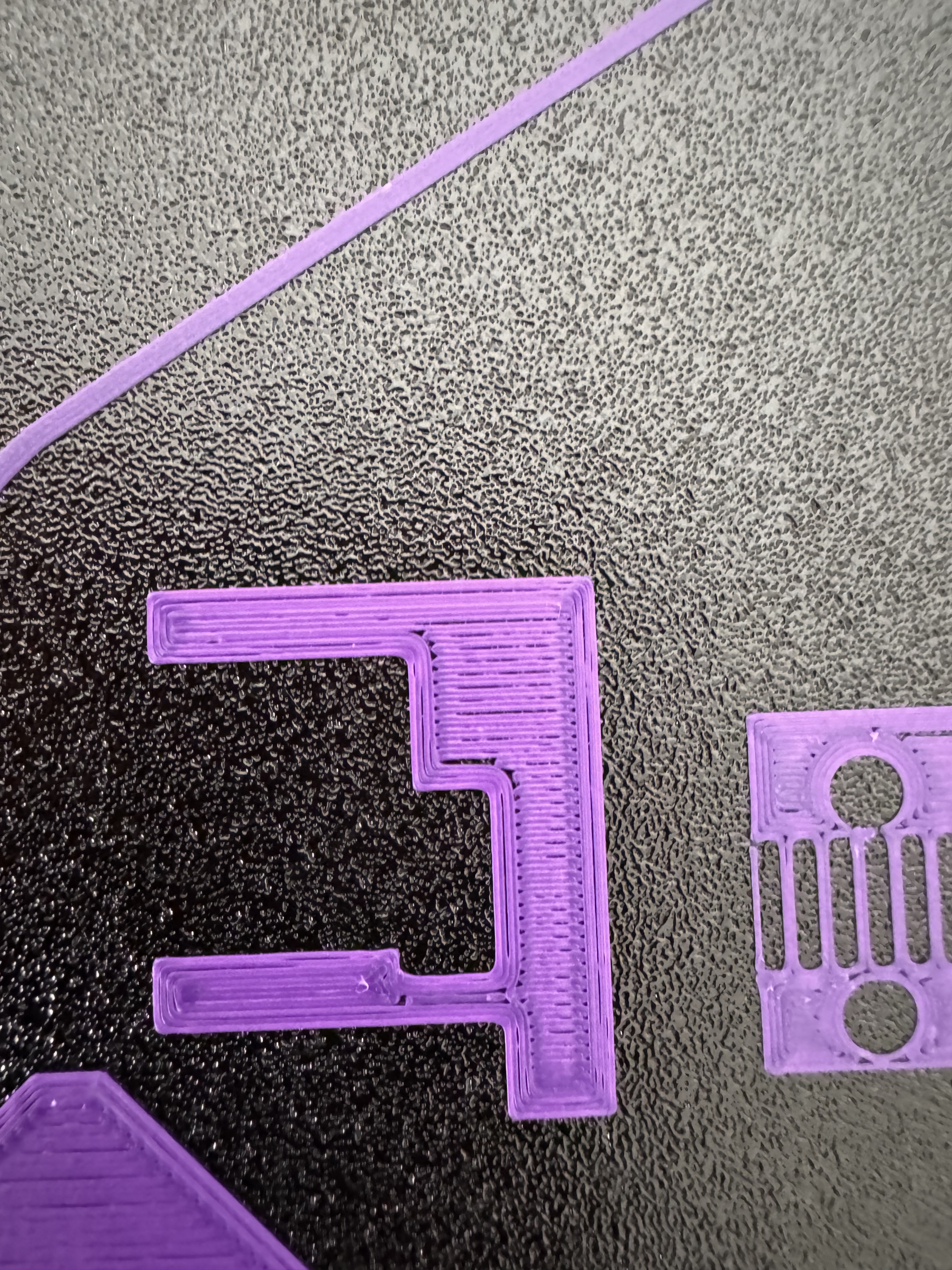

- the first object on the build plate with the first layer printed + the outer wall of the second layer (which looks completely off - the Z height seems to be gone),

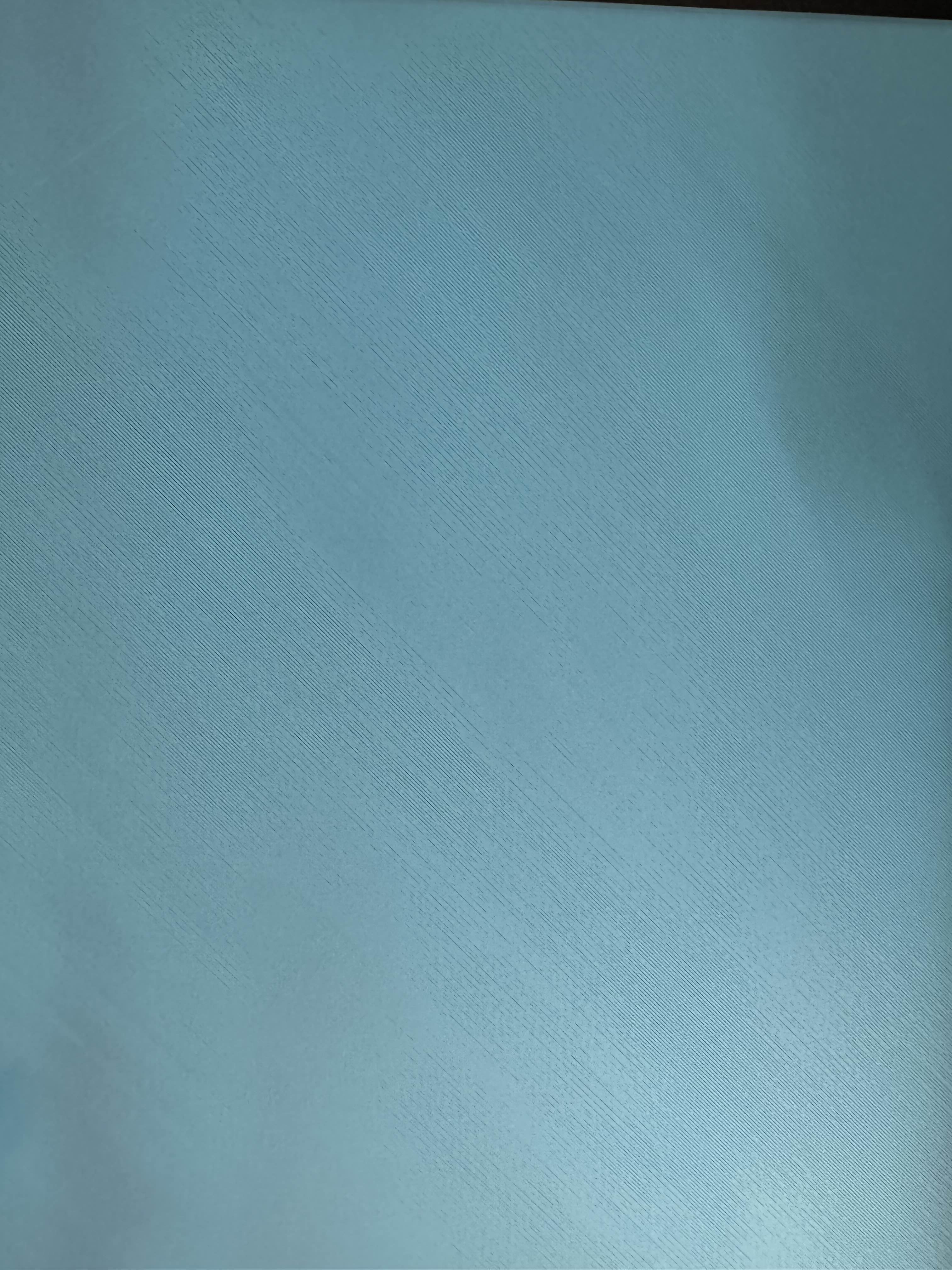

- and the first layer of the last object on the build plate.

I've got the titanium gantry upgrade installed and an internal heater. The printer has been heat soaked for 30 min for the bed and 5 min for the nozzle. The internal heater was on and got the chamber to ~60 degrees. The filament used is ABS. Is 30 mins not enough to heat soak an enclosed V-Core 400?

17 Replies

people with the 500s seem to have good luck with an hour, but I don't have any first-hand experience. Could try it out and see

Have you done all the orca tests for flow, retraction and PA?

I’ve used prusa slicer with ratrig punkfill profiles, sometimes the extrusion is perfect, sometimes there are visible empty lines in the infill, so I would not suspect the filament calibration to be the issue

You'll actually need to run all the filament unting processes in Orcaslicer, then you can go back to prusa and create the profiles if you want. Are you printing punkfill?

No, it was esun abs+. I’ll give it a try with the calibrations you mentioned and see if that helps. The odd thing is that sometimes it can print perfectly and sometimes there are visible empty lines

are you using .4 mm nozzzle or the .6?

your flow and PA have alot to do with how the outsider wall is going to look

You can also use the commissioning guide to set PA. I don't recall if the comissioning guide has a flow test.

.4 nozzle

Did you update all the input shaping numbers?

yes. Printing PLA unenclosed turns out quite ok, but when I enclosed the printer and started to print ABS I sometimes couldn't get a good 1 layer or during printing the 1 layer next objects would have too high Z offset. I'm heat soaking the machine for 60 mins before printing and that kind of helps, but I still get messed up 1 layers sometimes

You may have to just z for when you print pla vs abs due to gantry flex due to heat

Then just readjust when you bring either

I only really print abs and Asa on my 500

I also use vision miner bed adhesive

I’ve did all the calibration needed for the filament, done the beacon calibration once again, enabled beacon compensation and still this is the first later, it starts ok but after a while it looks like garbage. I’ve got the titanum gantry from toro, so I’m not sure what else I could do… Bed mesh is 0.25 after heat soak

Have you tried deleting the mesh info out of printer.cfg and doing it again? I think that has helped a few people

yes, I've done it. Nothing seems to help, the printer is unusable...

Hello @matithemati, have you found a solution to your problem? I am experiencing the same issue with a nearly identical printer configuration.

Hi, unfortunately without any luck. Replaced Orbiter and Rapido and the issue still persisted. At the moment the machine is sitting collecting dust, these problems are disqualifying the printer.

Ive experienced this too, for me it was caused by uneven heating caused by the chamber heater, as the heater was pointed towards one side of the bed/print chamber.

I suspect the back lead screw and the back side of the bed heated much faster then the front of the printer. The difference over the bed was probably more then a millimeter over the time of one layer

I’m finding preheating my setup for 30-40 min is the minimum for good print quality