TPU 90A: inconsistent extrusion

Errors

Errors Extrusion

ExtrusionPrinter:

RR3.2, EVA2, LGX/LGX Pro Metal, Mosquito Magnum, Nozzle E3D Brass 0.4

Filament: FormFutura Python Flex TPU 90A, Skin Tone ID2

Printsettings:

Tried 2-8mm3/s, 220-270°C, Filament dried.

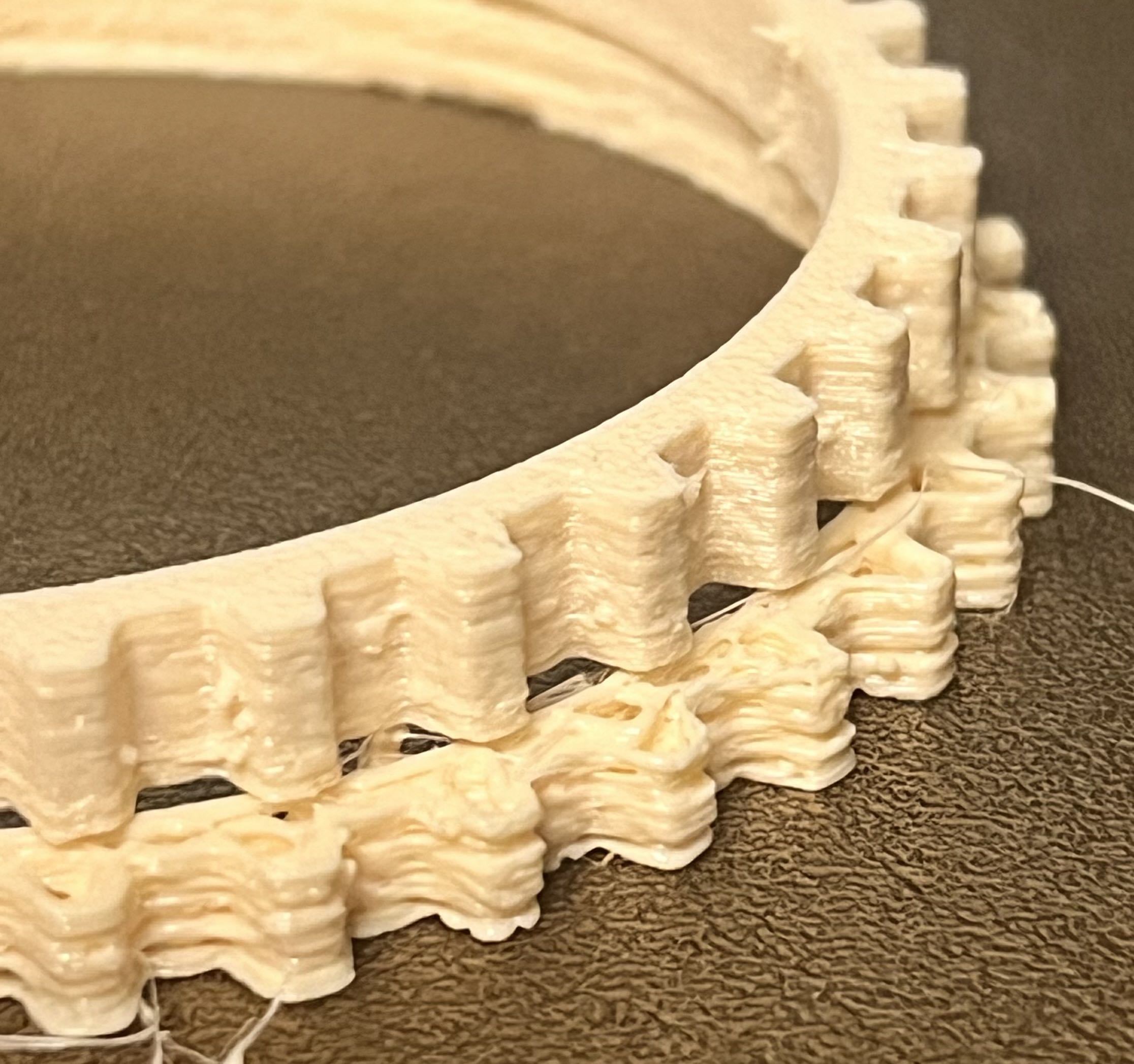

We experience super uneven surfaces (extrusion?) on objects with lots of corners; printing a cylinder with gyroid infill works flawless. The pictures show the comparison.

Where else could we search for the issue? Is the bowden path + cold section of the mosquito to long?

Mechanically we checked a lot: No gaps in filament path, new capricorn tube between extruder and hotend, pulling filament from the spool hanging above, turns very light.

Thanks in advance

RR3.2, EVA2, LGX/LGX Pro Metal, Mosquito Magnum, Nozzle E3D Brass 0.4

Filament: FormFutura Python Flex TPU 90A, Skin Tone ID2

Printsettings:

Tried 2-8mm3/s, 220-270°C, Filament dried.

We experience super uneven surfaces (extrusion?) on objects with lots of corners; printing a cylinder with gyroid infill works flawless. The pictures show the comparison.

Where else could we search for the issue? Is the bowden path + cold section of the mosquito to long?

Mechanically we checked a lot: No gaps in filament path, new capricorn tube between extruder and hotend, pulling filament from the spool hanging above, turns very light.

Thanks in advance

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)