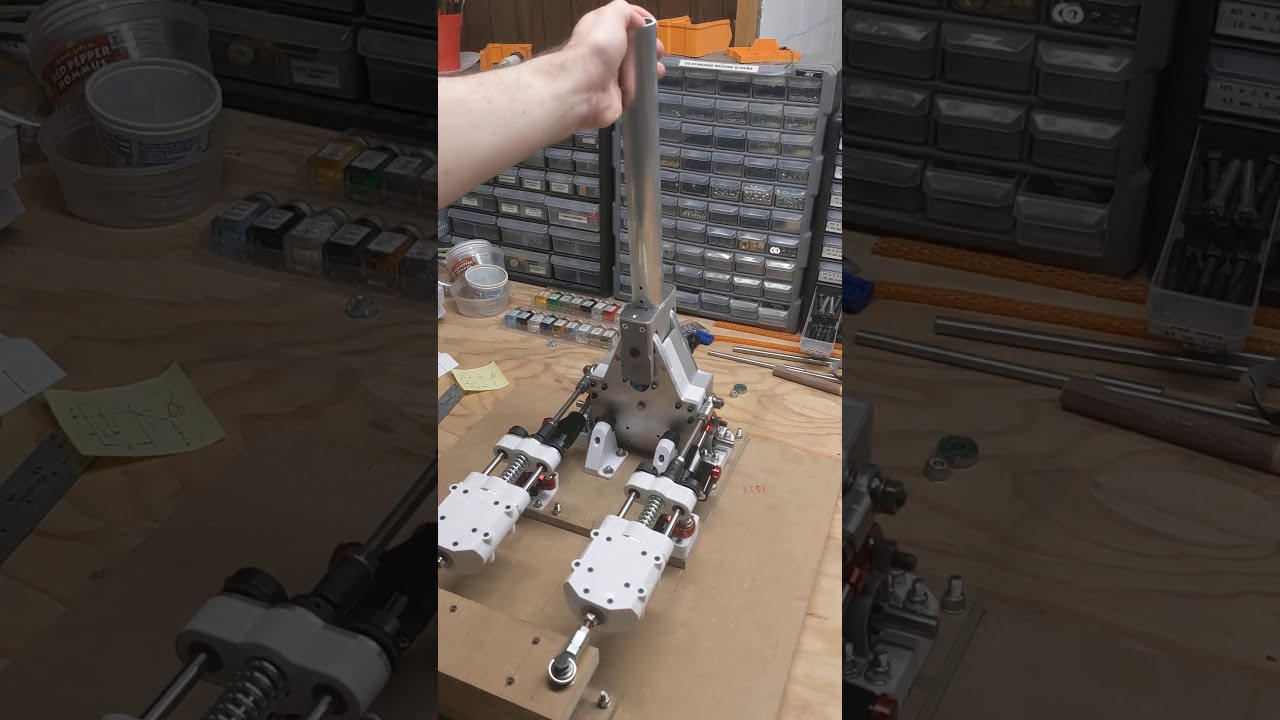

I’m guessing there’s a point to the belts being exposed, but I possess absolutely not one bit of tec

I’m guessing there’s a point to the belts being exposed, but I possess absolutely not one bit of technical knowledge to help answer that

very good insights! And the reasoning is very true. I thought about adding/releasing stl files for covers for small pulleys since this question comes up from time to time. The large pulleys have very limited range indeed.

very good insights! And the reasoning is very true. I thought about adding/releasing stl files for covers for small pulleys since this question comes up from time to time. The large pulleys have very limited range indeed.

handed off to couriers today :)

handed off to couriers today :)

faq

faq @authentikit

@authentikit

Thanks for the feedback!

Thanks for the feedback!