Using 90-degree traces in PCB design can bring about cost advantages due to several reasons:

Manufacturing Efficiency: Right-angle corners can be challenging for the etching process in PCB manufacturing, potentially requiring additional steps and precision. 90-degree angles are more easily accommodated in the manufacturing process, reducing the likelihood of errors and improving overall efficiency.

Reduced Production Time: The manufacturing equipment and processes are often optimized for simpler geometries, which include 90-degree angles. Using 90-degree traces can lead to quicker production times, contributing to cost savings.

Lower Fabrication Costs: Some PCB manufacturers might charge more for designs with tighter tolerances, including sharp angles. Using 90-degree traces can fall within standard manufacturing tolerances, helping to keep fabrication costs lower.

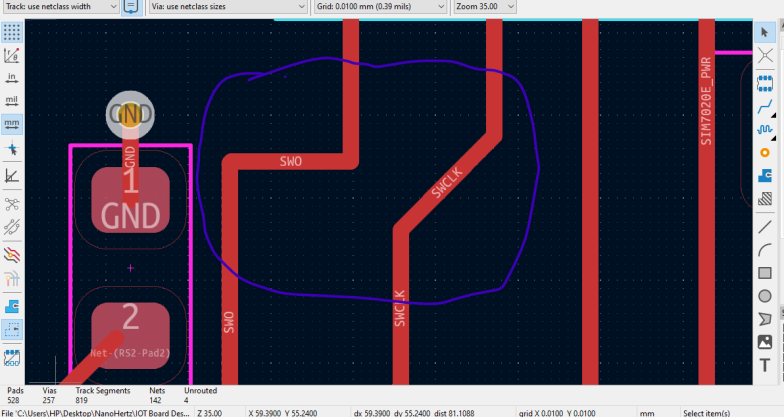

Minimized Signal Integrity Issues: Sharp corners in high-speed digital signals can lead to signal integrity challenges, such as reflections and impedance mismatches. Using 90-degree traces can help mitigate these issues, reducing the need for additional signal conditioning components or design iterations.

Ease of Design: Designing with 90-degree traces is often simpler and more straightforward. It can reduce the complexity of the layout process, making it easier for designers to achieve their goals without sacrificing performance.

It's essential to consider the specific requirements of your design and manufacturing processes to determine the most cost-effective approach. While 90-degree traces can offer advantages, the overall impact on cost may vary based on the complexity of the PCB and the capabilities of the manufacturer.