For any YTer asking for a review, Walmis should randomly pick 1 guy from the queue and send it to hi

For any YTer asking for a review, Walmis should randomly pick 1 guy from the queue and send it to him

.

.

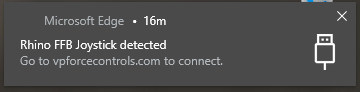

If I get it pretty quickly I can make it disappear. If I wait too long it'll get stuck on the screen until I reboot (even if I disconnect the rhino.)

If I get it pretty quickly I can make it disappear. If I wait too long it'll get stuck on the screen until I reboot (even if I disconnect the rhino.)