V4 500 IDEX shitload of small crums

Overtightened my primary extruder and now molten filament is streaming down from the direction of the heatsink. IDEX and Remap toolheads to the rescue... so I thought.

A small print approx. 20min prints flawless, but as soon as I print a large model little wisps and strands appear several layers in and the situation gradually grows worse and worse. In the end I end up with an unusable print and a build plate literally filled with broken off and tossed around crums.

Included pictures:

01 Small RJ45 cap which printed flawless

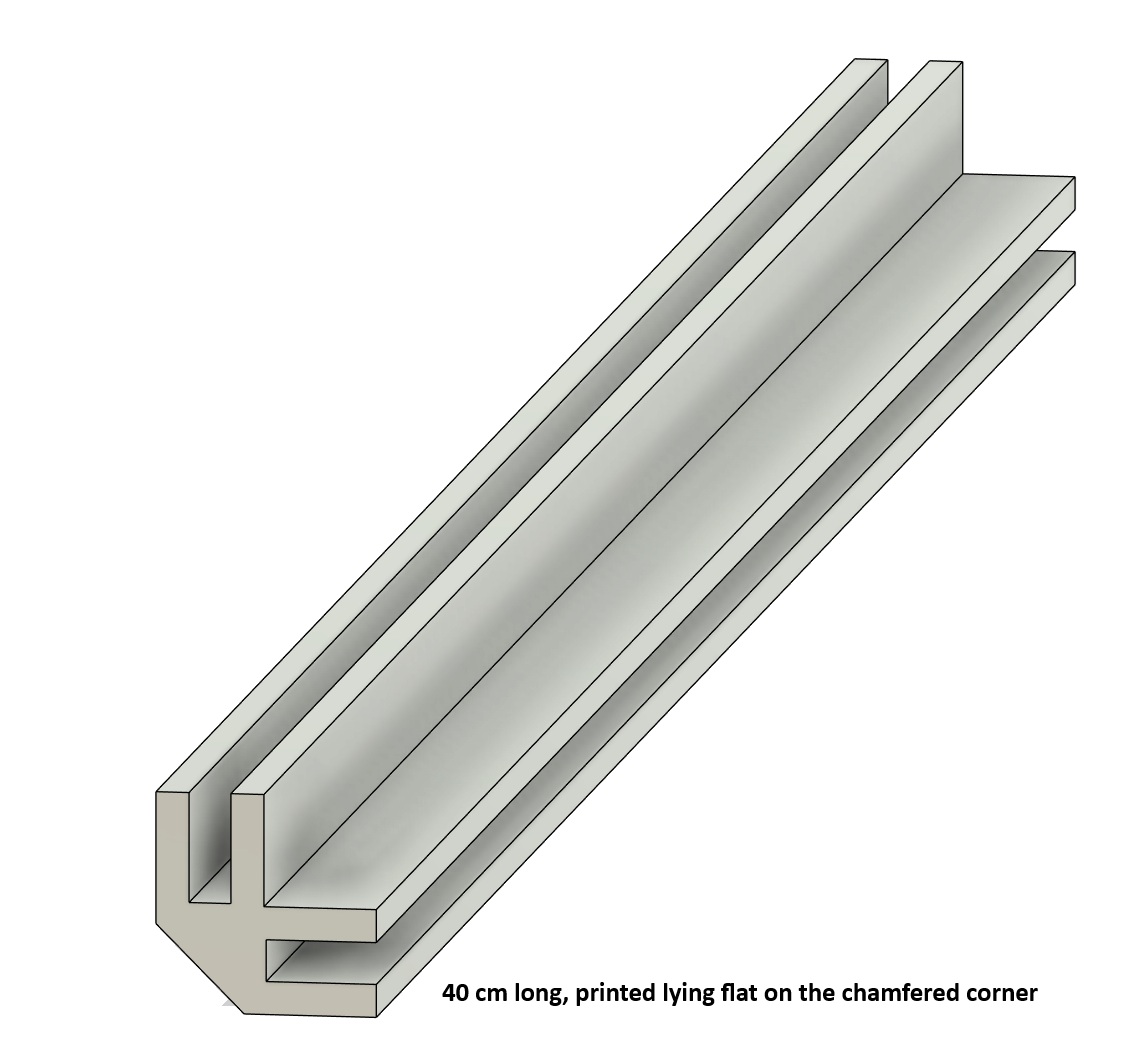

02 Large model to be printed (4 on a plate)

03 Resulting print halfway through

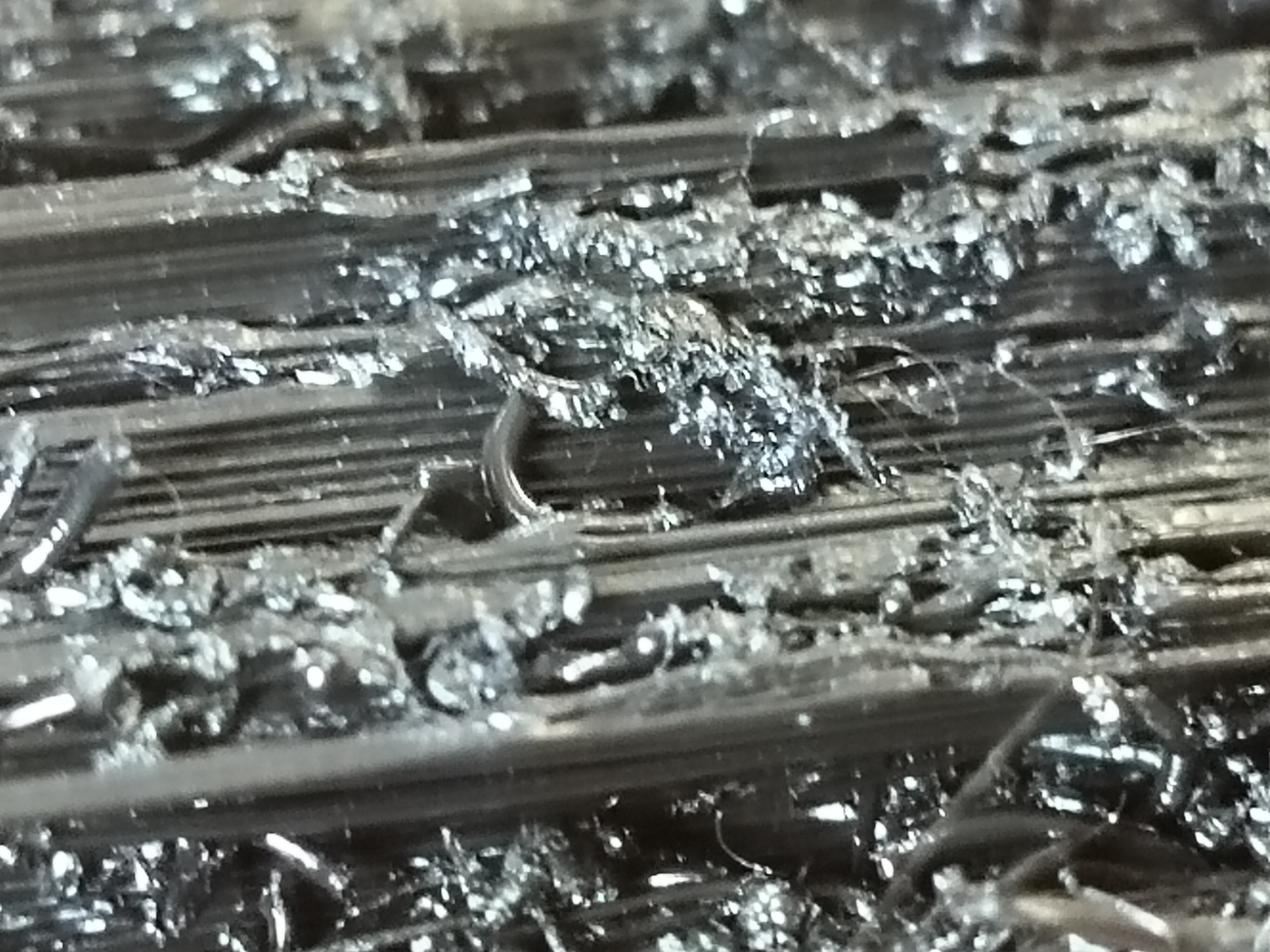

04 Some of the crums (microscope)

RatRig performed flawless for over 680 hours on the primary nozzle and having no clue what's causing this mess.

A small print approx. 20min prints flawless, but as soon as I print a large model little wisps and strands appear several layers in and the situation gradually grows worse and worse. In the end I end up with an unusable print and a build plate literally filled with broken off and tossed around crums.

Included pictures:

01 Small RJ45 cap which printed flawless

02 Large model to be printed (4 on a plate)

03 Resulting print halfway through

04 Some of the crums (microscope)

RatRig performed flawless for over 680 hours on the primary nozzle and having no clue what's causing this mess.

Solution

Ok, after printing a temp tower for the second hotend I upped the temperature from 210°C (best for first hotend) to 240°C (I'm printing PETG).

Now everything prints fine on the second hotend.

Which begs a new and different question...

Now everything prints fine on the second hotend.

Which begs a new and different question...

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)