Extremely inconsistent 1st Layer

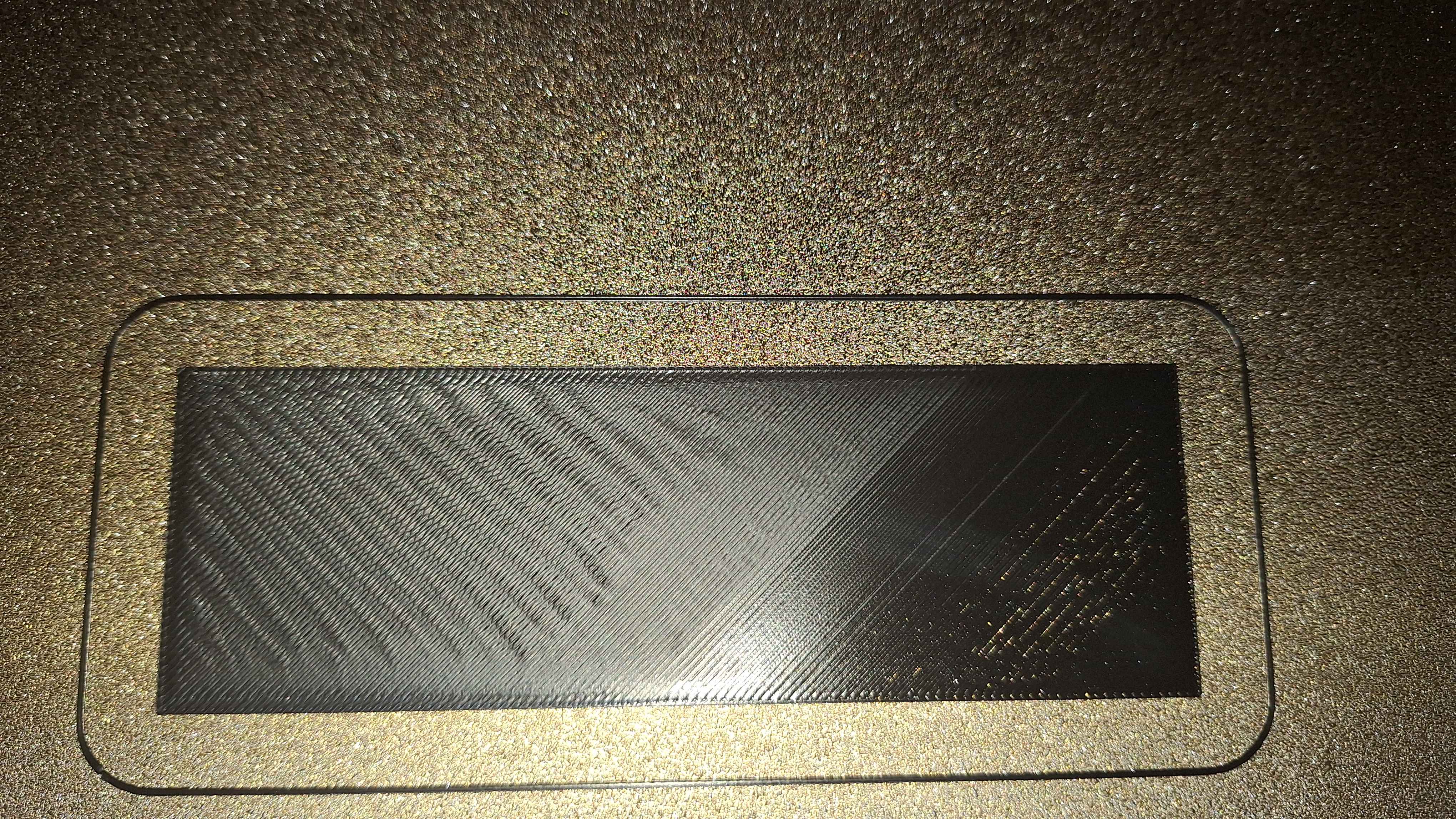

I'm at a loss. My 1st layer is extremely inconsistent. I have to babystep all 1st layers the whole time. It starts good, then falls off a cliff by being way too close to the bed. On this 50x150mm patch printed in the center I started high, got a good looking layer, then the nozzle goes way too close to the bed.

It doesn't matter what material, bed temp or hotend temp, the 1st layer never is right. Usually let the printer heatsoak for 30mims before evem homing just to get all parts nice and hot.

BEACON Calibration shows a 65um gantry twist, so far the best I achieved. Going lower is extremely hard.

Printer is a stock VC4 500 Hybrid built from the official RR kit including their printed parts, except the hotend which is a brand new Rapido 2F UHF with a 0.5mm hardened steel nozzle. Also has an enclosure and aftermarket PEI sheet. The stock one yielded the same results, extremely inconsistent 1st layer.

Stuff tried so far: hot mounting all linear rails, stock bolt pattern with 0.9Nm torque per screw.

Beacon calibration after 1h heatsoak with chamber closed and bed at 80C

New RatOS install

Prusaslicer downgrade to 2.9.0 (currently newest version with 2.9.2)

Old VC4 500 Hybrid slicer profiles and the newest ones.

Different 1st layer heights from 0.2-0.35mm

Different nozzles, E3D brass 0.4mm, Phaetus nickel plated copper 0.4mm, Phaetus hardened steel in 0.5 and 0.6mm

Checked correct nozzle sizes in both the slicer and RatOS

Nozzle and UHF adapter both torqued to Phaetus specs

Many different filaments and temp settings, PLA, PLA SILK, PETG, PETGCF, TPU, differnet brands, all spools dried for many hours

Currently using Prusaslicer 2.9.2 and the newly released RR profiles.

I hope someone smarter than me knows what's up, I can't print like this at all.

It doesn't matter what material, bed temp or hotend temp, the 1st layer never is right. Usually let the printer heatsoak for 30mims before evem homing just to get all parts nice and hot.

BEACON Calibration shows a 65um gantry twist, so far the best I achieved. Going lower is extremely hard.

Printer is a stock VC4 500 Hybrid built from the official RR kit including their printed parts, except the hotend which is a brand new Rapido 2F UHF with a 0.5mm hardened steel nozzle. Also has an enclosure and aftermarket PEI sheet. The stock one yielded the same results, extremely inconsistent 1st layer.

Stuff tried so far: hot mounting all linear rails, stock bolt pattern with 0.9Nm torque per screw.

Beacon calibration after 1h heatsoak with chamber closed and bed at 80C

New RatOS install

Prusaslicer downgrade to 2.9.0 (currently newest version with 2.9.2)

Old VC4 500 Hybrid slicer profiles and the newest ones.

Different 1st layer heights from 0.2-0.35mm

Different nozzles, E3D brass 0.4mm, Phaetus nickel plated copper 0.4mm, Phaetus hardened steel in 0.5 and 0.6mm

Checked correct nozzle sizes in both the slicer and RatOS

Nozzle and UHF adapter both torqued to Phaetus specs

Many different filaments and temp settings, PLA, PLA SILK, PETG, PETGCF, TPU, differnet brands, all spools dried for many hours

Currently using Prusaslicer 2.9.2 and the newly released RR profiles.

I hope someone smarter than me knows what's up, I can't print like this at all.

Solution

Next update after some prints: the Toro3D Ti tube is a MUST HAVE, every 1st layer is a DREAM now! So if anyone has the same issue with very inconsistent 1st layer on the VC4 500 or the VC4 in general, drop in the Ti tube and call it a day.

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)