Beacon angle off…

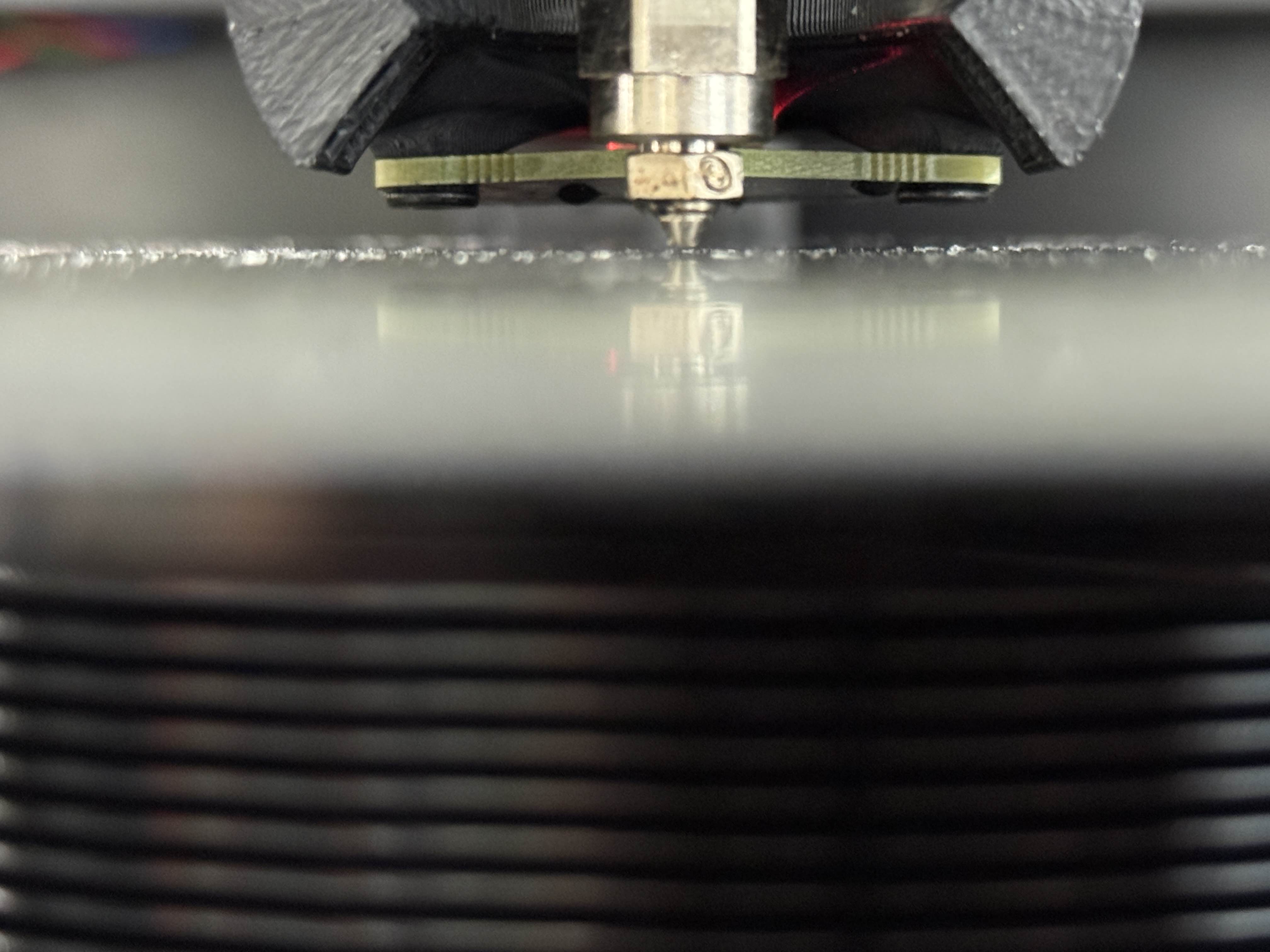

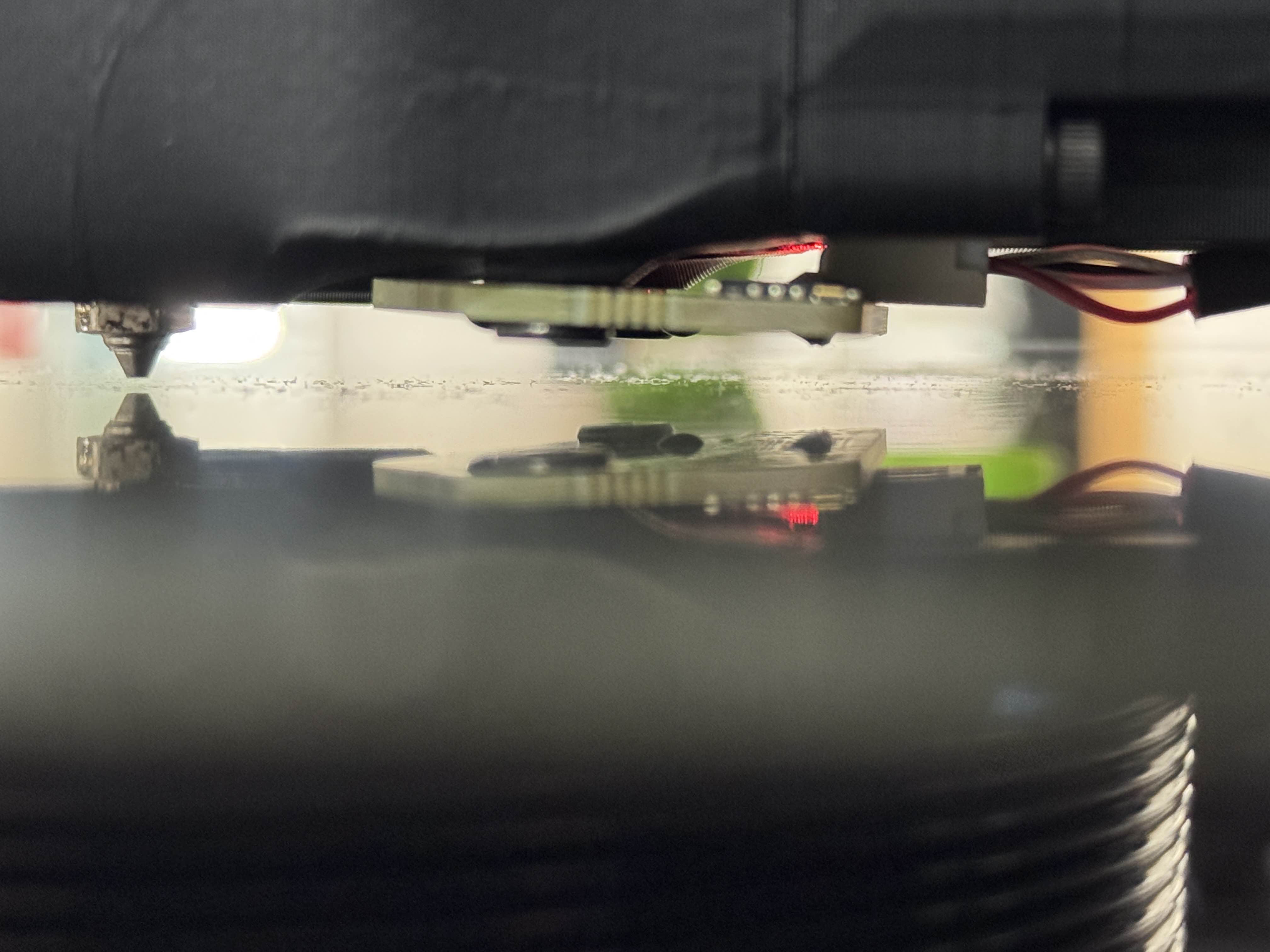

So I have a major issue getting my V-core 4 to put down any first layer I would call consistent or even mediocre. For months, I have been troubleshooting everything I have read that could cause issues with the first layer. By a fluke, when I was taking measurements, I noticed the Beacon PCB was anything but straight.

It slopes due to the printed part is badly printed, and the inserts are not put in straight.

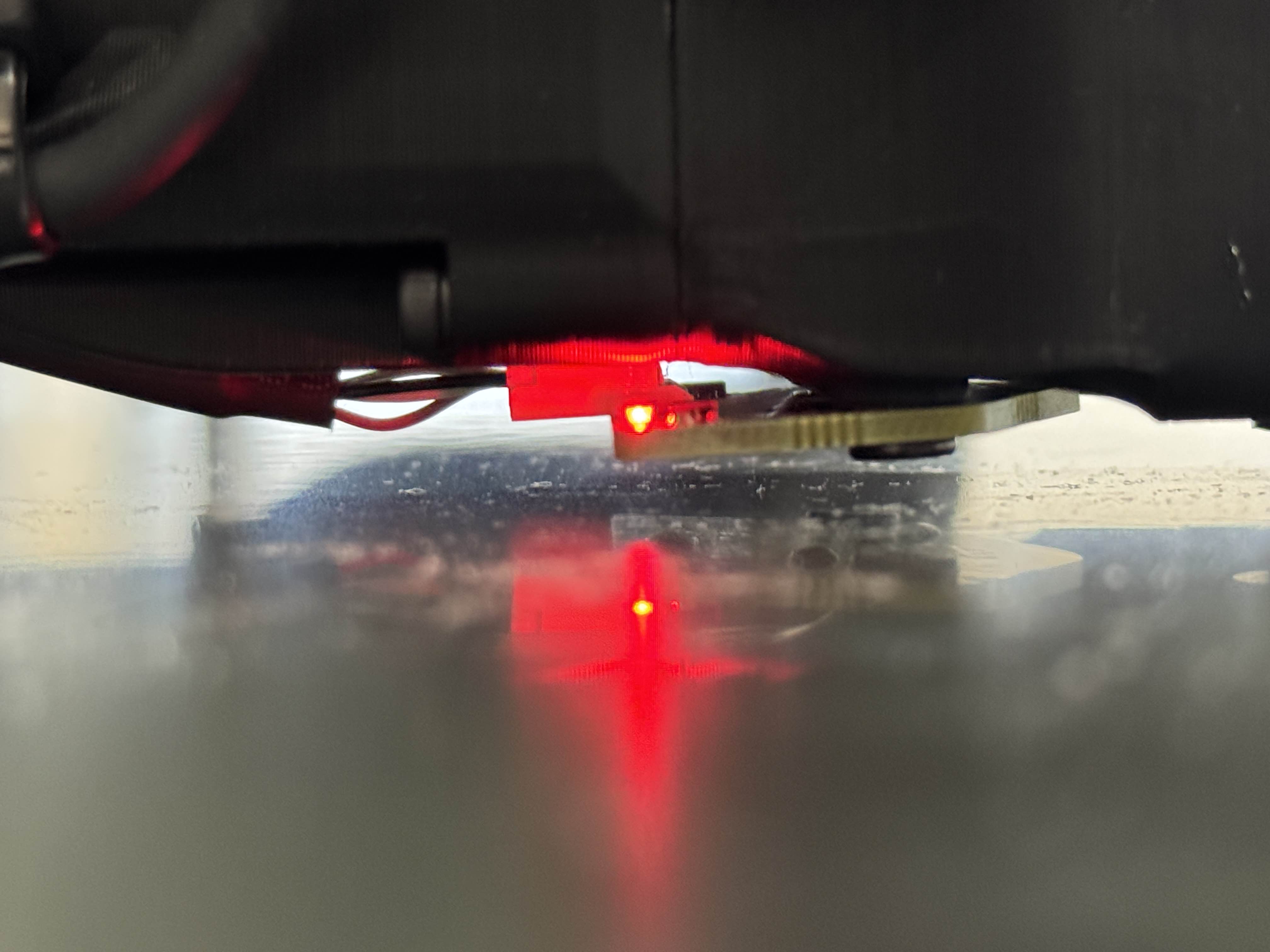

The distance from the nozzle to the bed in the photo is 0.5mm.

The distance from the back of the beacon PCB to the plate is 3.2-3.4mm.

The distance from the front of the beacon PCB to the plate is 4.4-4.7mm.

After checking the beacon documentation, I learned the difference between beacon contact, where the nozzle physically touches the bed plate to collect data, and beacon proximity, which probes the bed about 2mm above the bed surface. The latter is the default setting for doing z-alignment of the bed on the V-core 4 if I have understood everything correctly.

Could this be the cause of all my issues?

What kind of problems could this cause? According to the beacon documentation i could find that the offset from the tip of the nozzle to the bottom of the plate should be c:a 2.6 to 3mm. V-core 4 standard at least according to their CAD file is 2.89mm.

All thoughts or information are welcome! Hopeing to be able to print something with this machine before I lose my mind....

Thank you!

It slopes due to the printed part is badly printed, and the inserts are not put in straight.

The distance from the nozzle to the bed in the photo is 0.5mm.

The distance from the back of the beacon PCB to the plate is 3.2-3.4mm.

The distance from the front of the beacon PCB to the plate is 4.4-4.7mm.

After checking the beacon documentation, I learned the difference between beacon contact, where the nozzle physically touches the bed plate to collect data, and beacon proximity, which probes the bed about 2mm above the bed surface. The latter is the default setting for doing z-alignment of the bed on the V-core 4 if I have understood everything correctly.

Could this be the cause of all my issues?

What kind of problems could this cause? According to the beacon documentation i could find that the offset from the tip of the nozzle to the bottom of the plate should be c:a 2.6 to 3mm. V-core 4 standard at least according to their CAD file is 2.89mm.

All thoughts or information are welcome! Hopeing to be able to print something with this machine before I lose my mind....

Thank you!

![Rat Rig Community [Unofficial] banner](https://cdn.discordapp.com/banners/582187371529764864/4ee3e42e227d6aac26f048a3e69d5924.webp?size=480)