Remember to flick the force trim ingame switch from the cockpit. It works for UH-1 and makes a huge

Remember to flick the force trim ingame switch from the cockpit. It works for UH-1 and makes a huge difference.

faq and doing some very light googling. The motors you ordered appear to be the same ones that came in the base (per the notes in the #

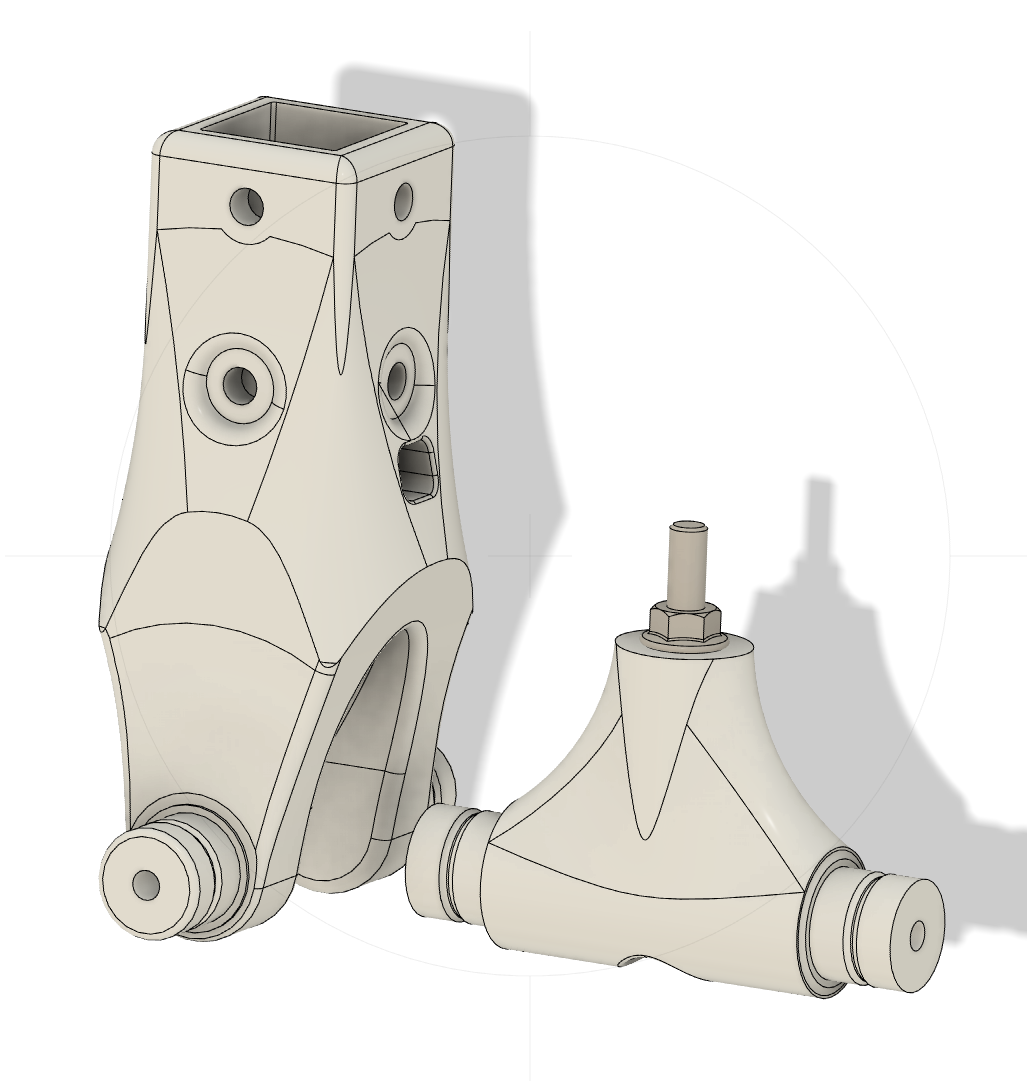

faq and doing some very light googling. The motors you ordered appear to be the same ones that came in the base (per the notes in the # faq). The stock power brick shipped with the bases is 180W. I've personally asked a similar question in here when I ordered stuff for my pedals (I want a single power supply, not two) and I bought a 350W. For you, I humbly believe a 240W would be fine.

faq). The stock power brick shipped with the bases is 180W. I've personally asked a similar question in here when I ordered stuff for my pedals (I want a single power supply, not two) and I bought a 350W. For you, I humbly believe a 240W would be fine.