Its not hard to find someone who can print. I am sure someone here can help.

Guys are out there any lefthanded players who use righthanded grips for flying simulation like VKB MCG ?

Thank you!

Thank you!

All of them.

think He meant left handed

think He meant left handedouncan use any and all vkb grips with the rhino. Hiwever Not natively. oull need a Blackbox and the VPForce VKB adapter

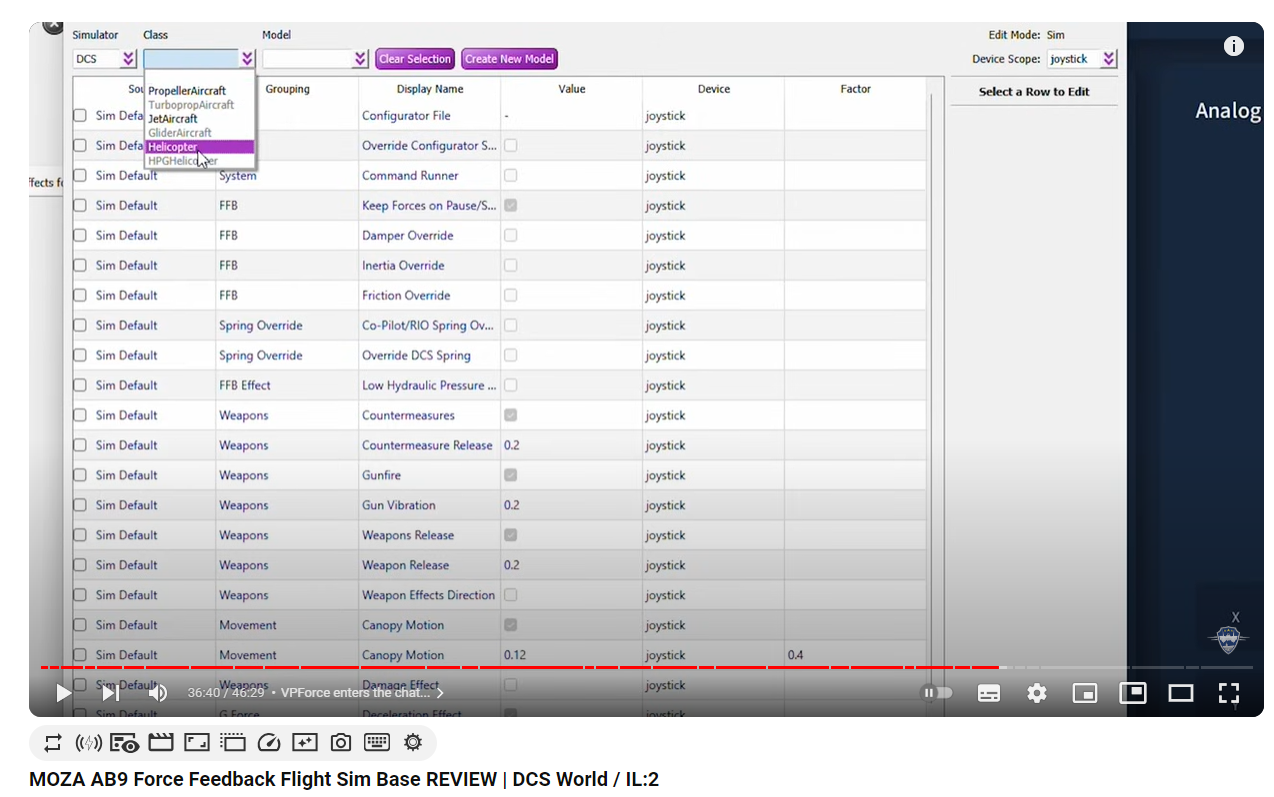

hello guys I was away for quite some time - few months - do we have new software for the rhino just saw the review from jabber for the monza FFB base and he featured a short piece for the rhino and he featured a software I haven't saw before ... is that something new?

telemFFB was completely overhauled at the beginning of the year. no more editing text files! https://github.com/walmis/VPforce-TelemFFB/releases/

GitHub

DCS FFB Telemetry Effects (for VPforce FFB). Contribute to walmis/VPforce-TelemFFB development by creating an account on GitHub.

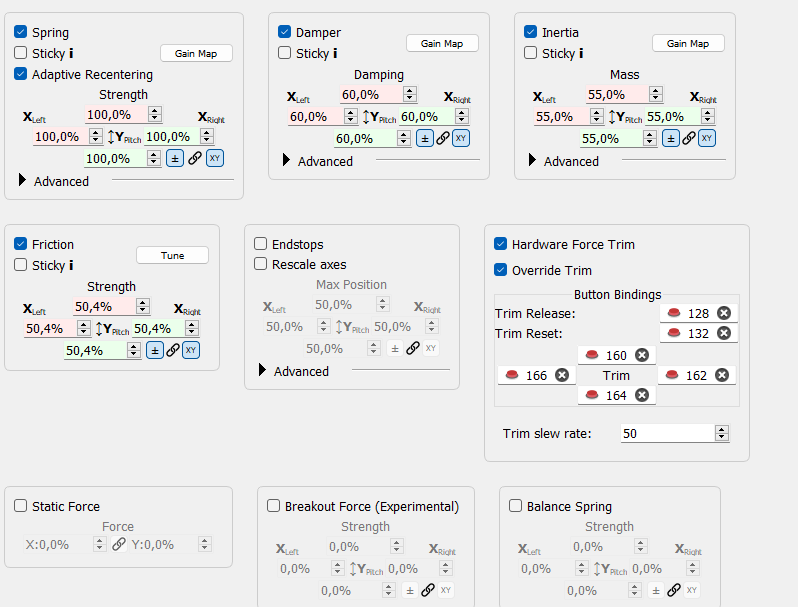

well its great flying this stick in a helicopter. I read and watched some stuff but I clearly am to stupid to find out how program the trim function to work. I have the trim release and the trim reset bound to up and down on lets say 4-waybutton A. That's enough vor my helicopters. But i also have bound my 4 buttons below the trim reset in de configurator on a 4-waybuttons say B vor when i fly aircraft. But its either both activated of non at all. I have hardware force trim ticked and override trim. I tried different combination together with buttons in the sim bound to trim of not. I cant understand how it works. In override trim, you don't bind any keys in DCS to the trim. You only use the hardware trim of the Rhino i believe. but the other trim buttons are active to on the mentioned button b (trim up,dw,lft,rgt). So i loose a button. How do i set this up so that button A up and down is trim release en trim reset when i fly helicopter. But NO function on button B (trim up/wn/lft/rght), and how do i engage the trim on button 2 for an aircraft but then no trim release of reset on button A). I tried videos,etc... guess I am no digital guy. But... anyway, Rhino is fantastic as is. Thx for the patient person to answer me.

so button A would be 128+132 and button B 160/162/164/166. Thx

And atm I have no buttons bound in DCS.

What you have set there is the hardware trim feature in configurator. As soon as you start DCS, all of that gets overridden by the DCS native spring effect.

You could enable the "sticky" option in the spring settings in upper left, but what you should do is set up your trim release/reset bindings in DCS. Since DCS has native FFB support, you don't need to use the hardware trim features in configurator.

The "override trim" option sort of acts as a "sticky" for those hat trim bindings, but here, too, you should bind them in DCS (but not many helis in DCS have hat/beep trims.. The MI-24 is the only one I know that does...)

You could enable the "sticky" option in the spring settings in upper left, but what you should do is set up your trim release/reset bindings in DCS. Since DCS has native FFB support, you don't need to use the hardware trim features in configurator.

The "override trim" option sort of acts as a "sticky" for those hat trim bindings, but here, too, you should bind them in DCS (but not many helis in DCS have hat/beep trims.. The MI-24 is the only one I know that does...)

thx, it works. (i had written it didnt, but i am a moron who switched the up and down button....)

It probably doesn't help dcs modules can vary between defining trim from a stick to nose perspective.

So depending on this the nomenclature for trim up/down become inverted.

So depending on this the nomenclature for trim up/down become inverted.

I have a large motor waiting for the MFG STL file to make the motor support. Even if @walmis is not ready or able to make the kit could he consider to release the STL for the motor support and pulley so the DIY people can use it. I don’t like my large motor kit sitting around waiting for the 3D print parts and unfortunately I don’t have the design skills to do that myself.

SimFab and OpenWheeler Officialmanager

Stick base mounts on SimFab seat frame center tube. Bracket replaces and deletes the standard “centered stick lower mount bracket”.

that's really neat

:package:  RHINO #0669 Has Shipped!

RHINO #0669 Has Shipped!

RHINO #0669 Has Shipped!

RHINO #0669 Has Shipped!I stared at it too long and pulled the trigger, oops

And the DCS rig kit it goes to

Guess my nearly decade-long era of relying on fold-out tables and chairs is going to be behind me

Is this just the plate or does it include other stuff. I’m wanting to use the plate to connect to some 4040 extruded aluminum

Any owner of the DCS FC24 module able to shed some light to it's ffb support? Mainly curious for the sabre, mig15, f5 and f15c.

Just the bracket. It connects to the seat frame they make

I can trial the older FC stuff, I guess I'll do that first.

I suppose the newer FC24 planes should have the same ffb support as their full fidelity counter parts, can anyone confirm?

For clarity, or at least my interpretation, the square frame that it's pictured with, it does not come with it. Despite being included in all the photos

If you want to buy a complete kit with that, get the Flight Sim Cockpit - DCS Edition. The $599 one. It's expensive but it has everything you need, including 3 different kind of universal adapter plates to mount other sticks/throttles. Except for the VPForce, they had to make a separate individual plate for that

I tried to buy the parts individually to see if I could scrub some unneccessary stuff and save money (essentially instead of buying the cockpit kit, I buy the rudder kit, seat, frame, extentions etc and do it separately that way) but even without a right side mount, it still comes out more expensive than the big bulk cockpit kit.

Better to just roll with the $599 item and then tack on the VP adapter

Making your own rig from aluminium profiles can be a lot cheaper, but you’ll have to make a design of your own.

You can also just 1:1 rip existing aluminum profile design from places like Monster Tech or TrakRacer etc. Super easy by referencing their manuals. Even easier with a part list that gives dimensions.

Honestly the hard part is sourcing all the important parts like connectors etc.

Getting aluminum profiling in correct dimensions isn't hard, but figuring out the other stuff can be annoying if you are unfamiliar with it all. I still feel super lost trying to navigate the big supplier sites trying to find everything I'd need to DIY on my existing rig.

Honestly the hard part is sourcing all the important parts like connectors etc.

Getting aluminum profiling in correct dimensions isn't hard, but figuring out the other stuff can be annoying if you are unfamiliar with it all. I still feel super lost trying to navigate the big supplier sites trying to find everything I'd need to DIY on my existing rig.

If you can't find a suitable supplier who does uni connector bores (/can do them yourself), it's also an option to go with external corner brackets for everything instead.

Those are generally easier to find, and more flexible in slot dimension requirements etc.

Of course, like uni connectors, they have their own considerations.

The main thing is to find a suitable profile series, and to stick with that as much as possible.

(For example: 40-series metric, i-type slot-8).

Makes your life a lot easier.

Those are generally easier to find, and more flexible in slot dimension requirements etc.

Of course, like uni connectors, they have their own considerations.

The main thing is to find a suitable profile series, and to stick with that as much as possible.

(For example: 40-series metric, i-type slot-8).

Makes your life a lot easier.

I built mine all from extruded aluminum 4040. It had been too bad to find components that work and match my 4040 aluminum is from the UK so I have to buy most everything online to be compatible. It’s really solid though.

Yeah, I just need the plate. I bought the one made by monster Tech, but I don’t like that. It only uses one side to secure the rhino.

Yeah there's various suppliers and most of the ones do cut stuff to your request including special things like threadings in various diameters, or to do cutouts for internal brackets (like what Monster Tech uses)

Does VP have software for bass shakers that could complement the base?

No. The way the motors generate haptic effects and the way a bass shaker work have almost zero in common. One is programmatically starting/stopping one or more periodic effects with a few frequency/intensity parameters... the other is essentially engineering a library of sound waves that will excite a speaker transducer.

Thanks!

I’ll tell you though, that my vpforce powered collective hard mounted to my chair does a pretty damn good job. I haven’t bothered to reconnect my buttkicker

I think I said this in support the other day

But one of the coolest things I noticed with the VPF was that it creates its own haptic effects

The frequency that the motors can achieve is surprising. Like with engine vibration

Its so fast but so small, I can't see it looking at the stick. But grab onto it, and I can really feel it shaking in my hand

It doesn't need some spinning unbalanced motor, or transducer. It creates vibration the good old fashioned way

just shaking the shit out of itself

I was surprised when I started writing effects for TelemFFB at how well it can even handle multiple simultaneous effects. Rotor whirl + jet engine + cannons? No problem.

It's also what makes it seem like blackmagic, and why at least to me Rhino will always be king. The only thing that could be better is if Walmis makes a new and improved Rhino v2.0. Which is in no way necessary, but who knows what the future holds.

Regardless, what has been cooked up by Walmis, and huge contributors from the community such as your self, is something truly special nowhere else can come close to touching.