The shaft winding technique req a cross-hole in the drive shaft, and 3-4 full wrapps of cable either

The shaft winding technique req a cross-hole in the drive shaft, and 3-4 full wrapps of cable either side of the hole before going to the final pully. The advantage of this type of system is it allows extremely small drive 'gear', allowing high ratios in compact form factor. Also eliminates the need for matching belts/pulleys. You just need to figure out a way to tension the cable in situ, which there are several ways to accomplish.

Kevlar rope is ideal for this because it has almost zero stretch where steel cable is rellatively springy. Kevlar stretch like 1-2% @ 50% break strength, steel is like 20% iirc.

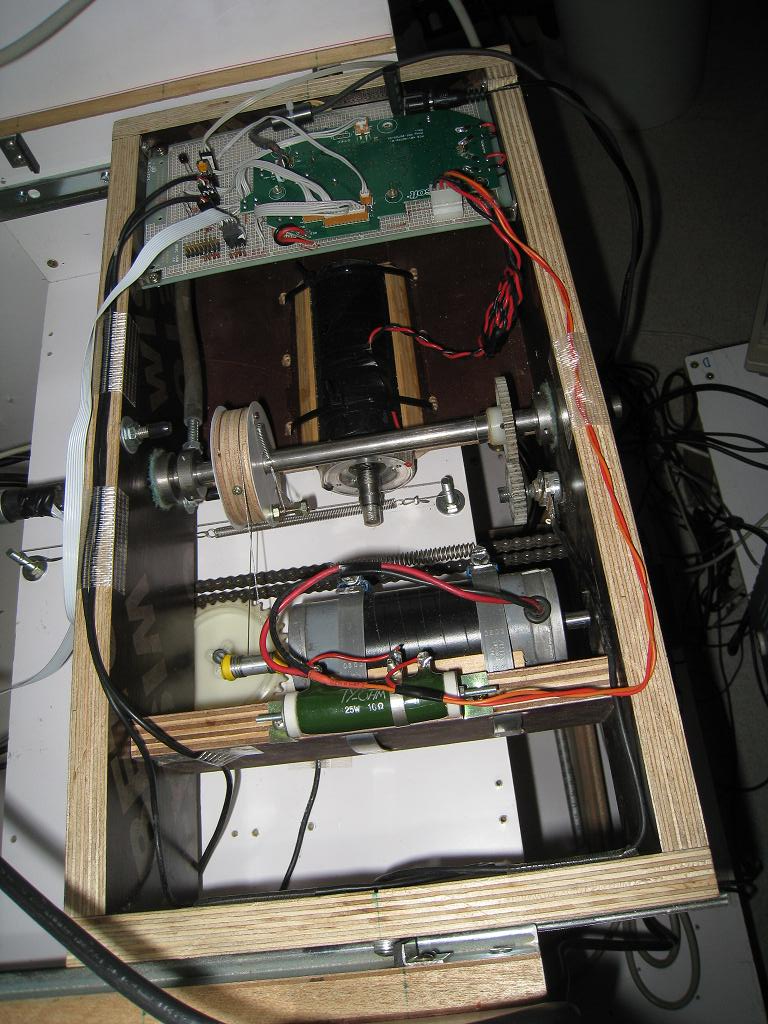

Here's an example of shaft winding, using steel cable in this case.

Kevlar rope is ideal for this because it has almost zero stretch where steel cable is rellatively springy. Kevlar stretch like 1-2% @ 50% break strength, steel is like 20% iirc.

Here's an example of shaft winding, using steel cable in this case.