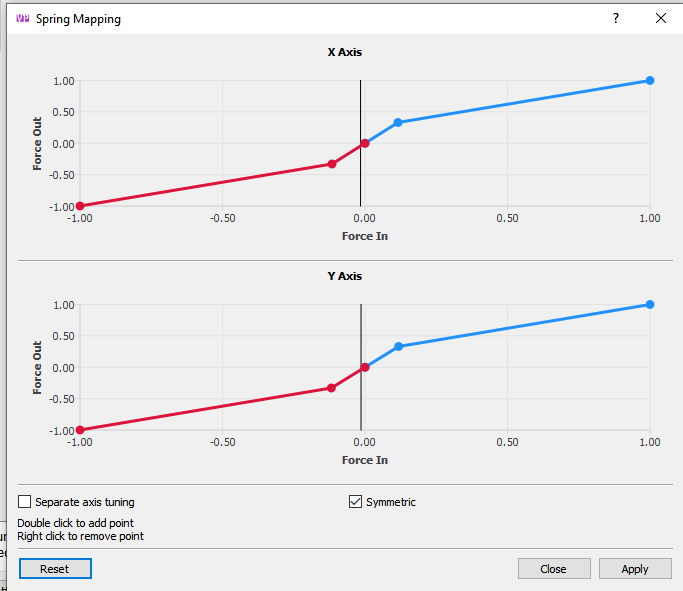

The only way is to tune the spring mapping, something like:

The only way is to tune the spring mapping, something like:

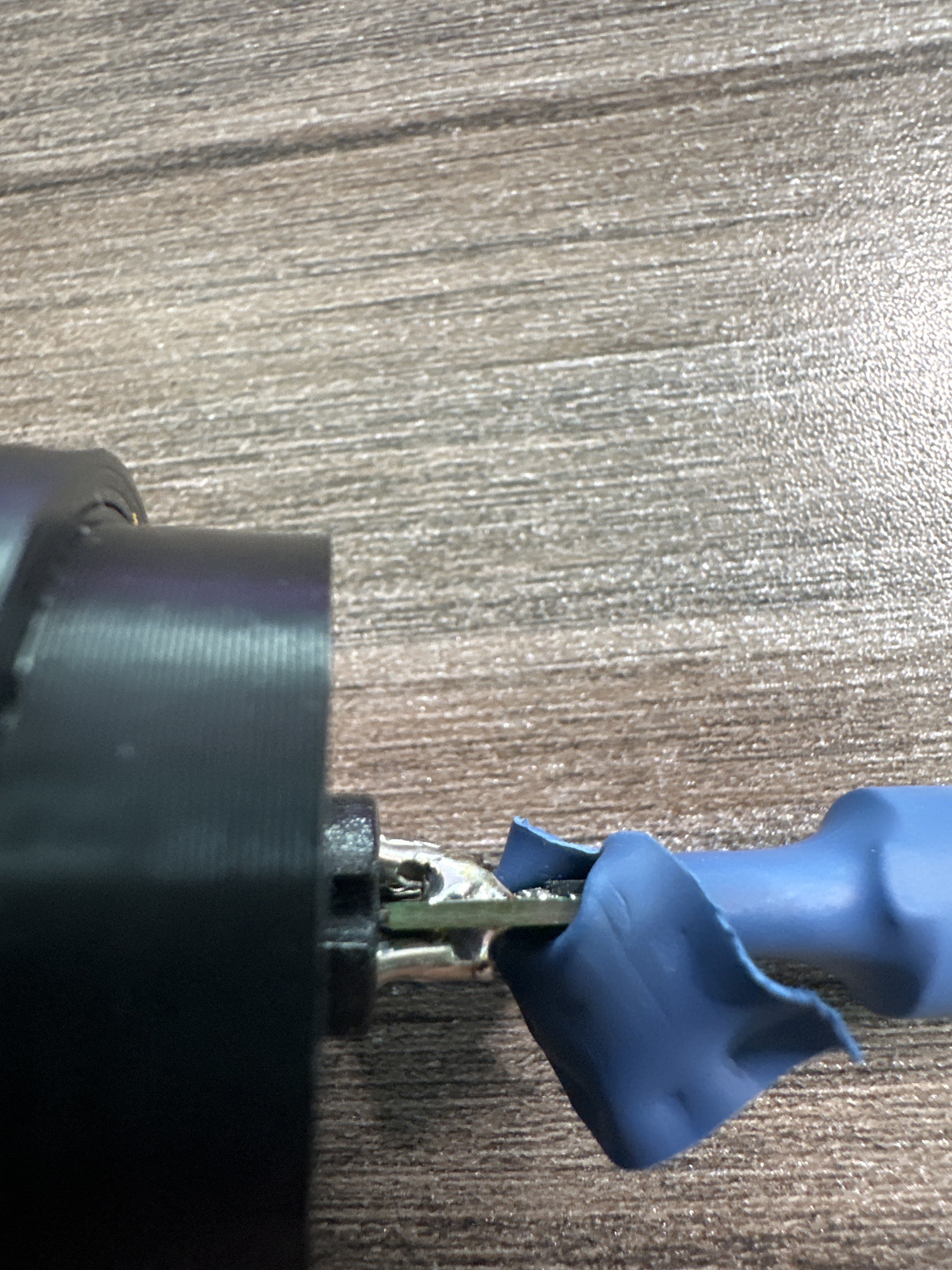

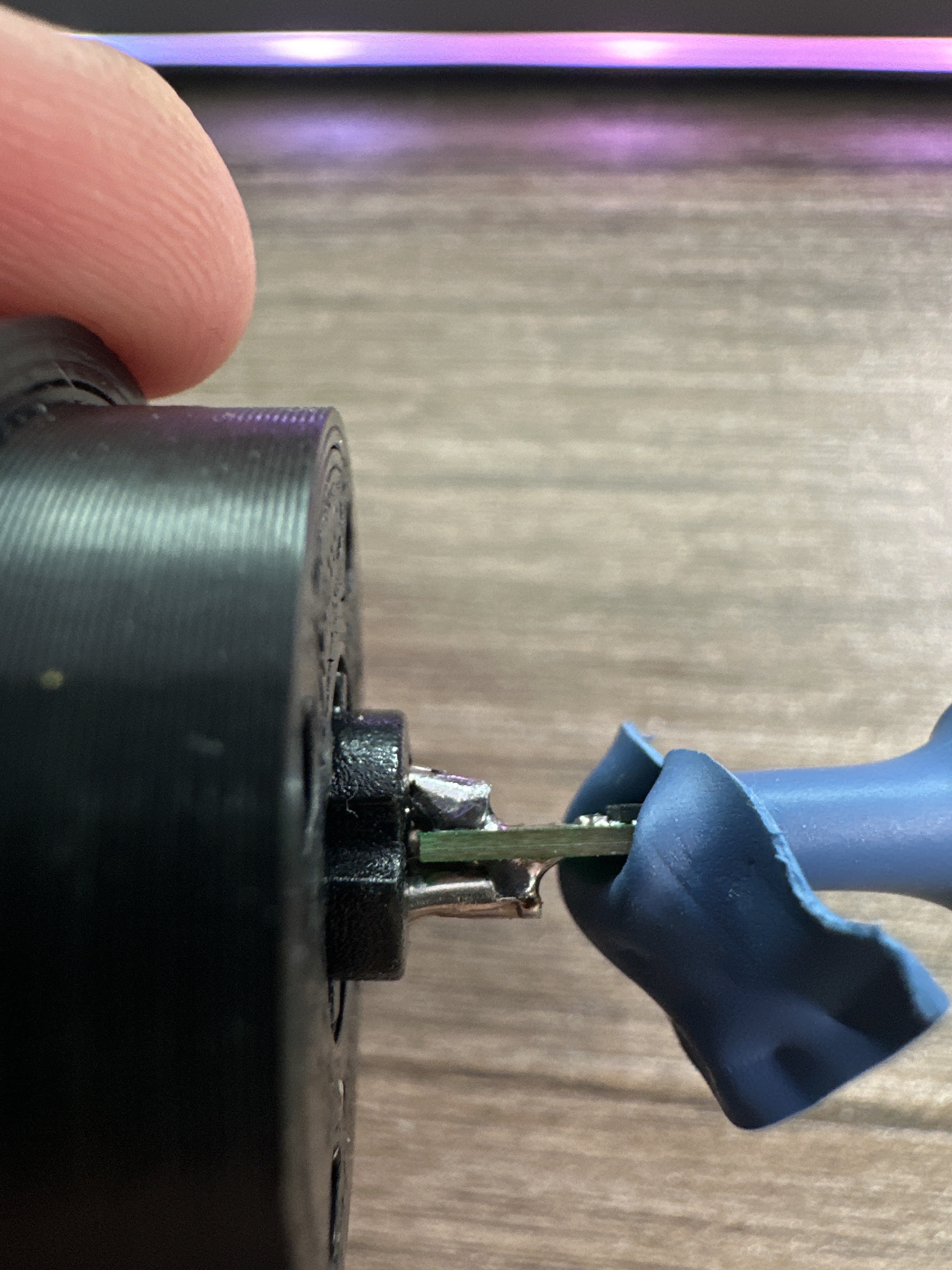

Rhino -> Thrustmaster WH Joystick Grip

Rhino -> Thrustmaster WH Joystick Grip Rhino -> Virpil Z-Extension -> Thrustmaster WH Joystick Grip

Rhino -> Virpil Z-Extension -> Thrustmaster WH Joystick Grip WW Orion 2 Base -> WW F16EX Grip

WW Orion 2 Base -> WW F16EX Grip Rhino -> Virpil Z-Extension -> WW Adapter -> F16EX Grip

Rhino -> Virpil Z-Extension -> WW Adapter -> F16EX Grip Rhino -> WW Adapter -> F16EX Grip

Rhino -> WW Adapter -> F16EX Grip

Let me know if you want to try.

Let me know if you want to try.

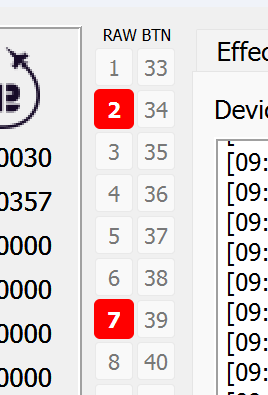

FF FF FF FF FF FF FF 00 00 08 00 08 00 08 00 08[10:18:21.030] FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF