I guess you'd install FFB on your pedals so you wouldnt have to remove the spring between fixed wing

I guess you'd install FFB on your pedals so you wouldnt have to remove the spring between fixed wing and rotary every (bloody!) time?

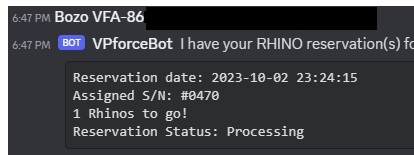

RHINO #0470 Has Shipped!

RHINO #0470 Has Shipped! RHINO #0471 Has Shipped!

RHINO #0471 Has Shipped!