Hey, I'll research this, but in the meantime you can do something like this: Let's say you're buildi

Hey, I'll research this, but in the meantime you can do something like this:

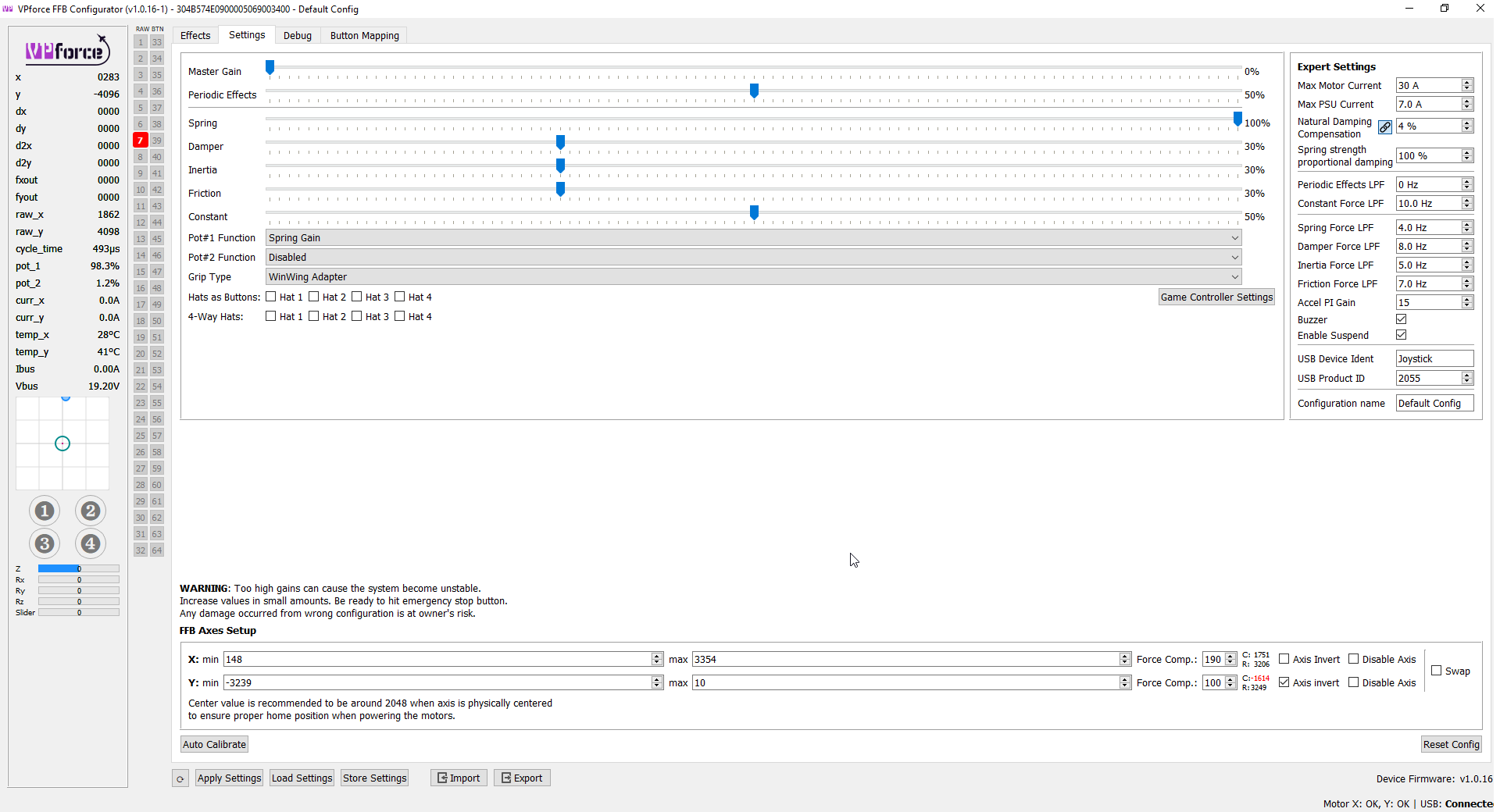

Let's say you're building a yoke and when powering it you need it to startup in the correct calibration. Now, let's say the simplest the position to startup is the fully forward one (for a stick it would be centered).

Then what you would do is to push it fully forward, reset the motors and check what the "raw" angle is. Adjust the belt/pulley so it's roughly 2000(+-500).

Next do the full auto calibration and store it.

After that, before powering on, move the yoke fully forward and it should start in the correct calibration every time.

Let's say you're building a yoke and when powering it you need it to startup in the correct calibration. Now, let's say the simplest the position to startup is the fully forward one (for a stick it would be centered).

Then what you would do is to push it fully forward, reset the motors and check what the "raw" angle is. Adjust the belt/pulley so it's roughly 2000(+-500).

Next do the full auto calibration and store it.

After that, before powering on, move the yoke fully forward and it should start in the correct calibration every time.