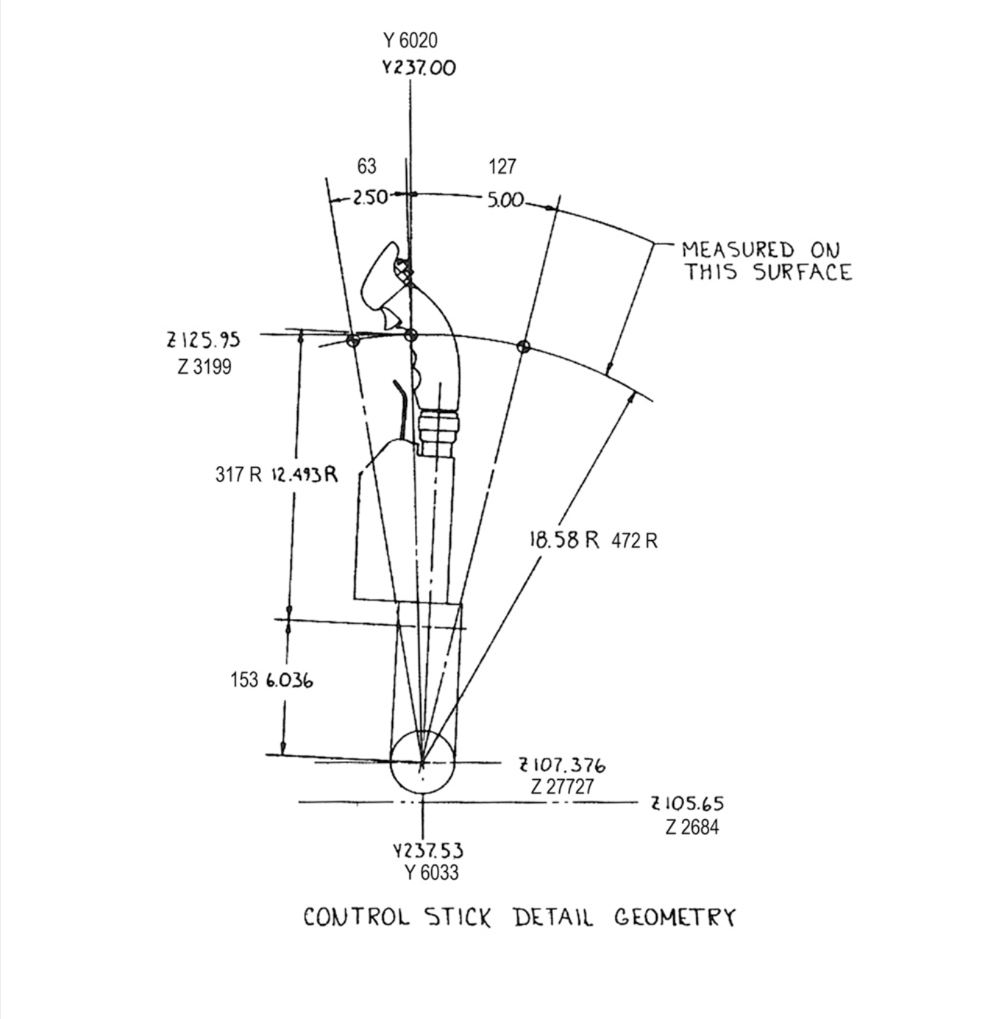

Although having used a 10KG force joystick I've become a huge fan of not having realistic forces hah

Although having used a 10KG force joystick I've become a huge fan of not having realistic forces haha, 4-5KG peak is my sweet spot

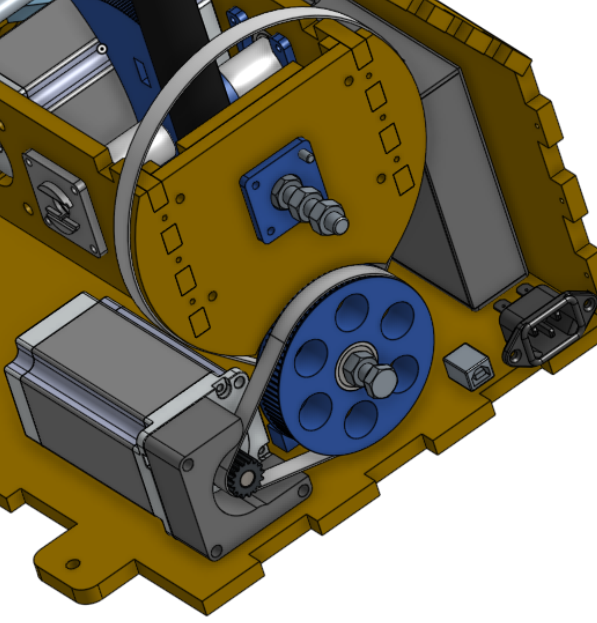

I'll chime in. So yeah there are couple of design decisions and compromises for the Rhino. I wanted to make a more accessible base and to keep the weight down while having decent forces. If it beats a Brunner offering then it's a win for me. And the shipping costs worldwide go exponentially with weight

I'll chime in. So yeah there are couple of design decisions and compromises for the Rhino. I wanted to make a more accessible base and to keep the weight down while having decent forces. If it beats a Brunner offering then it's a win for me. And the shipping costs worldwide go exponentially with weight  So material selection was based on that idea also. So I consider the Rhino as the 'advanced' entry level FFB device and once this project grows, I'll have more resources to start offering more PRO solutions.

So material selection was based on that idea also. So I consider the Rhino as the 'advanced' entry level FFB device and once this project grows, I'll have more resources to start offering more PRO solutions. Even the 57BLF did provide 5-6kg at the stick (=20-30Nm)

Even the 57BLF did provide 5-6kg at the stick (=20-30Nm)