I’m not sure what you mean. It’s doesn’t do this when connected to my Winwing base.

I’m not sure what you mean. It’s doesn’t do this when connected to my Winwing base.

RHINO #0803 Has Shipped!

RHINO #0803 Has Shipped!

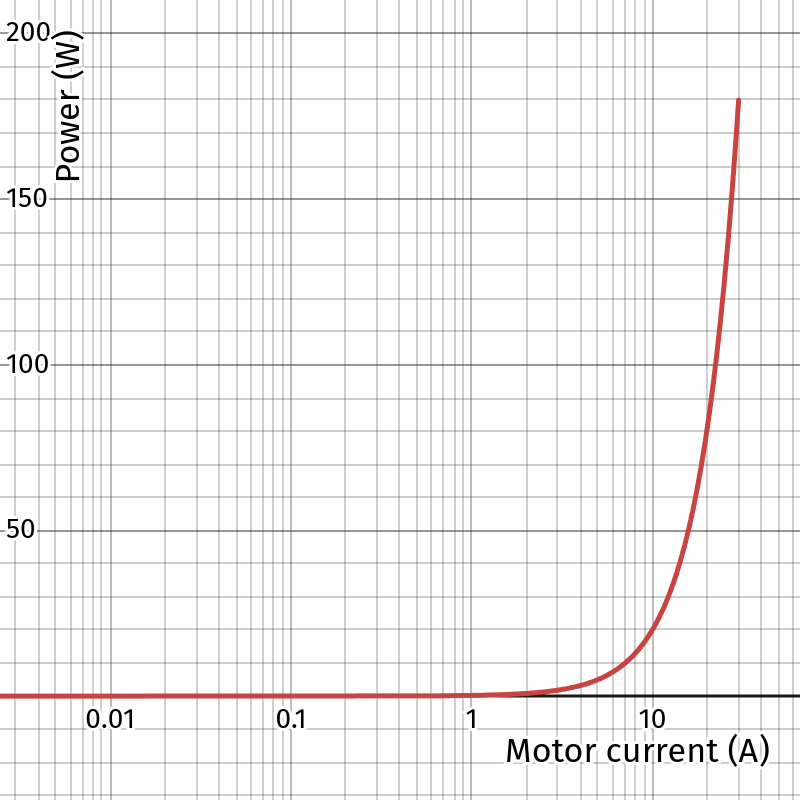

. @walmis What is the current draw of the 86BLF04?

. @walmis What is the current draw of the 86BLF04?

motor amps != PSU amps