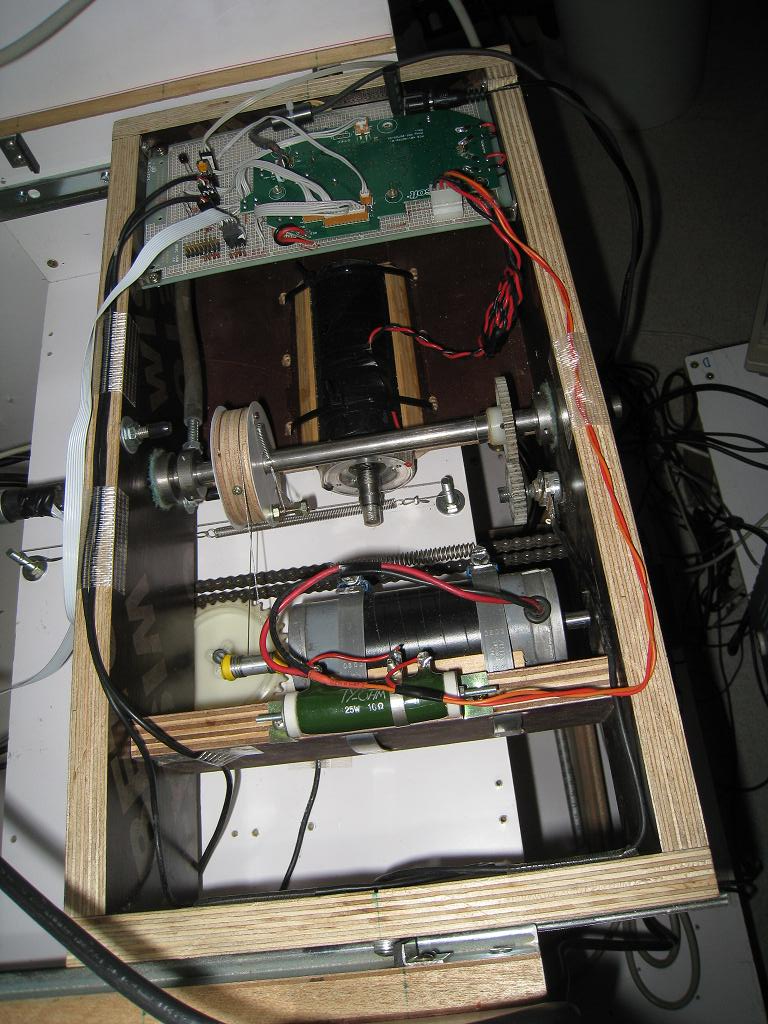

Mate just get a whole plywood board and bolt that to the pedals and bolt the stick to that. Then use

Mate just get a whole plywood board and bolt that to the pedals and bolt the stick to that. Then use the weight of your chair to keep it stable

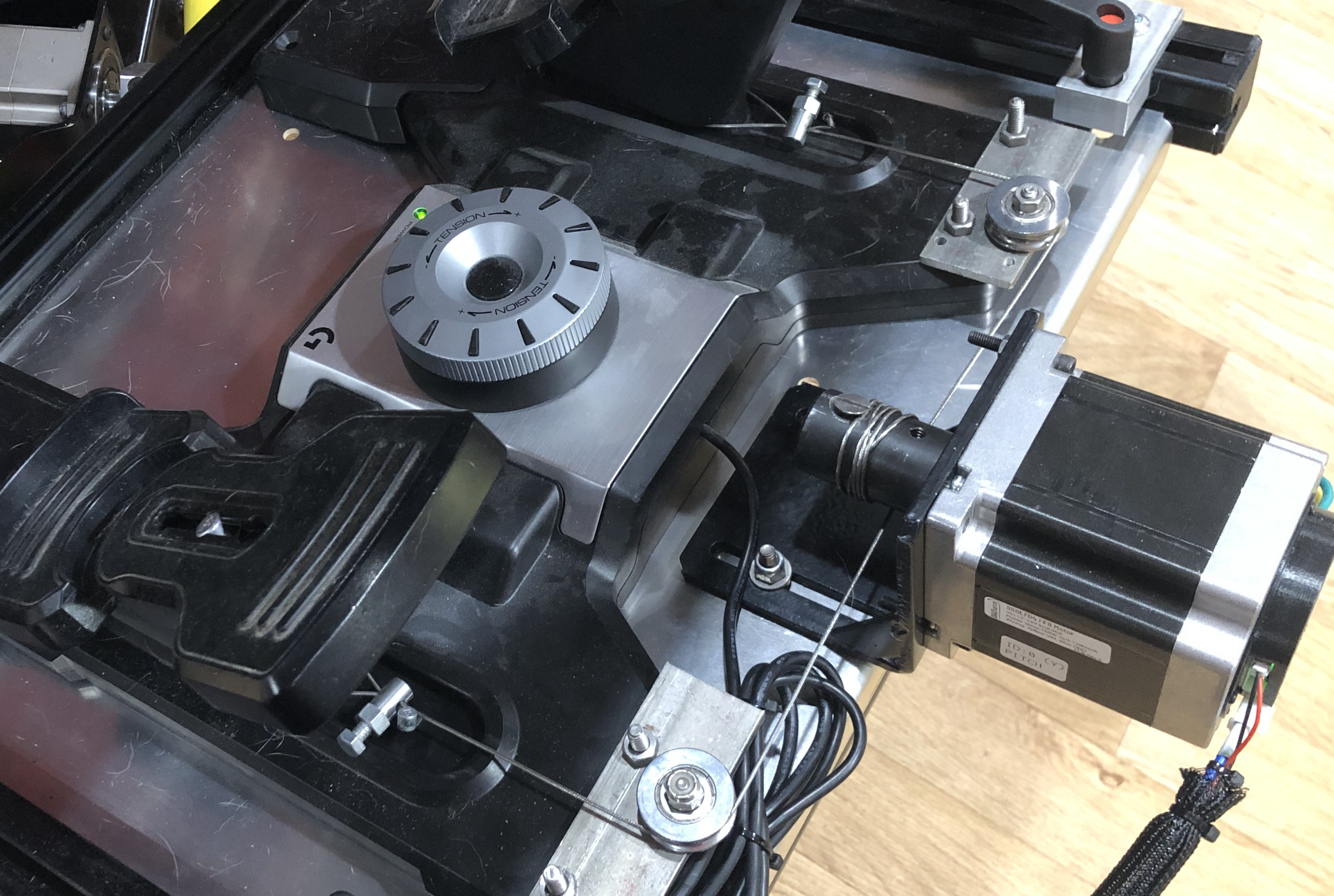

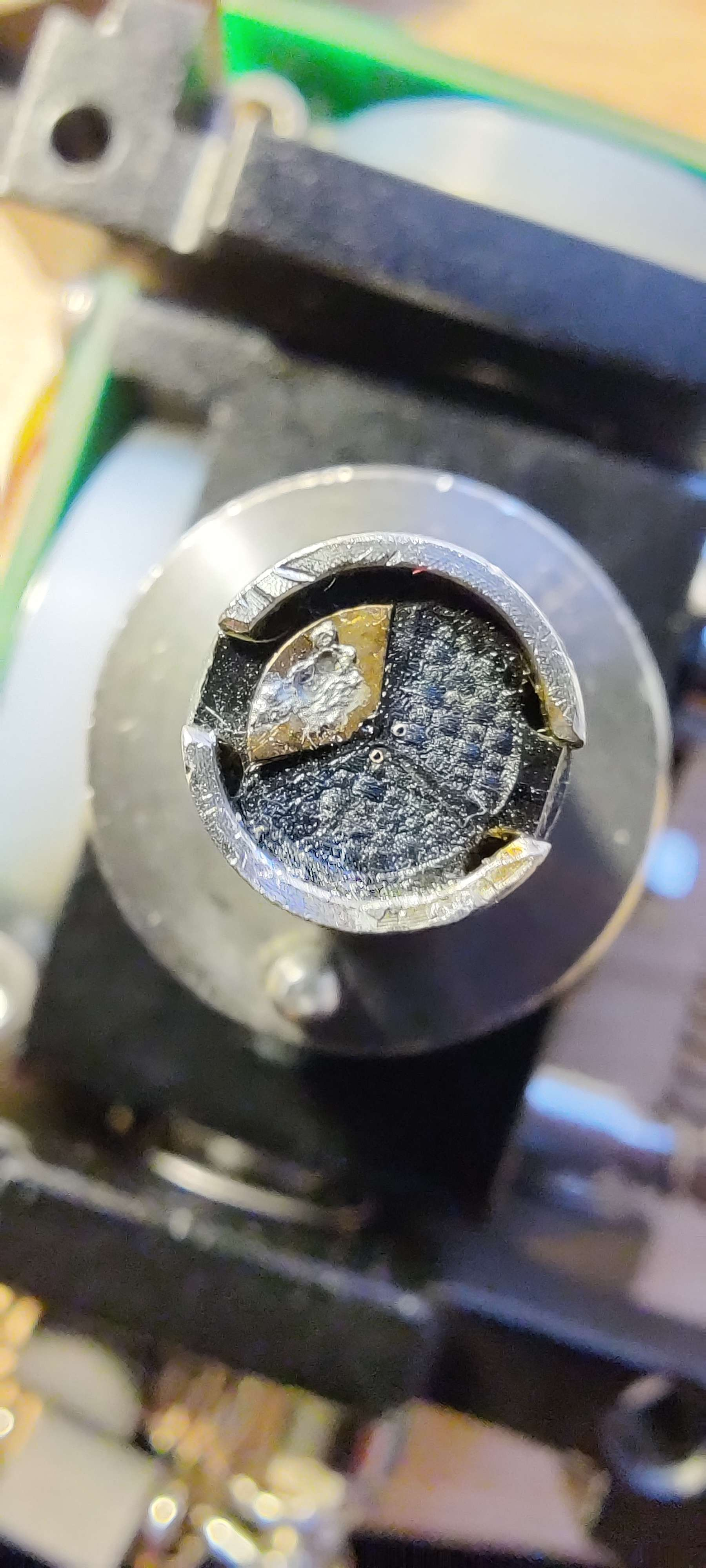

RHINO #0087 Has Shipped!

RHINO #0087 Has Shipped! RHINO #0089 Has Shipped!

RHINO #0089 Has Shipped! RHINO #0090 Has Shipped!

RHINO #0090 Has Shipped! (whilst we wait for the better solution from Walmis for MSFS that is)

(whilst we wait for the better solution from Walmis for MSFS that is)