Yes, I may. But I just wanted to see if anyone knew of a good online shop.

Yes, I may. But I just wanted to see if anyone knew of a good online shop.

faq .. probably answers a lot of questions you have.

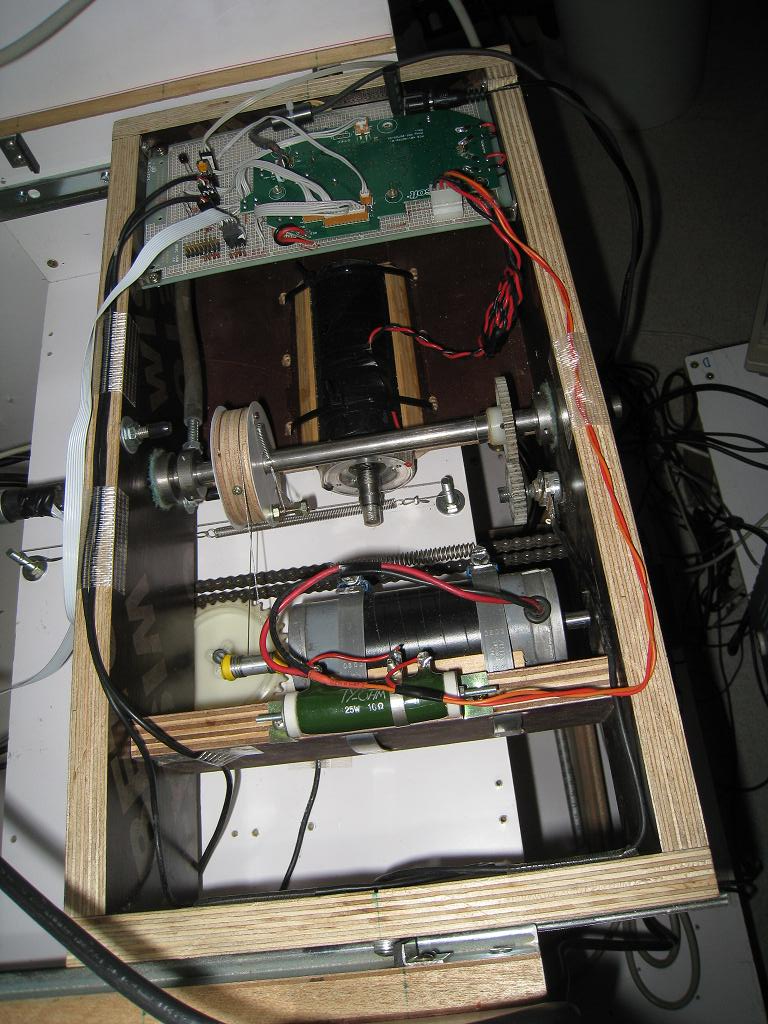

faq .. probably answers a lot of questions you have. I couldn't model the cable in CAD, but it is anchored and tensioned around the back side of one of the edge pulleys (you cant see it but there is a hole where the tensioning bolt will be right behind the top edge pulley. The other side of the cable is wrapped around another edge pulley and fixed in place. This gives 50 degrees of rotation so I'm still limited by the gimbal arms.

I couldn't model the cable in CAD, but it is anchored and tensioned around the back side of one of the edge pulleys (you cant see it but there is a hole where the tensioning bolt will be right behind the top edge pulley. The other side of the cable is wrapped around another edge pulley and fixed in place. This gives 50 degrees of rotation so I'm still limited by the gimbal arms.