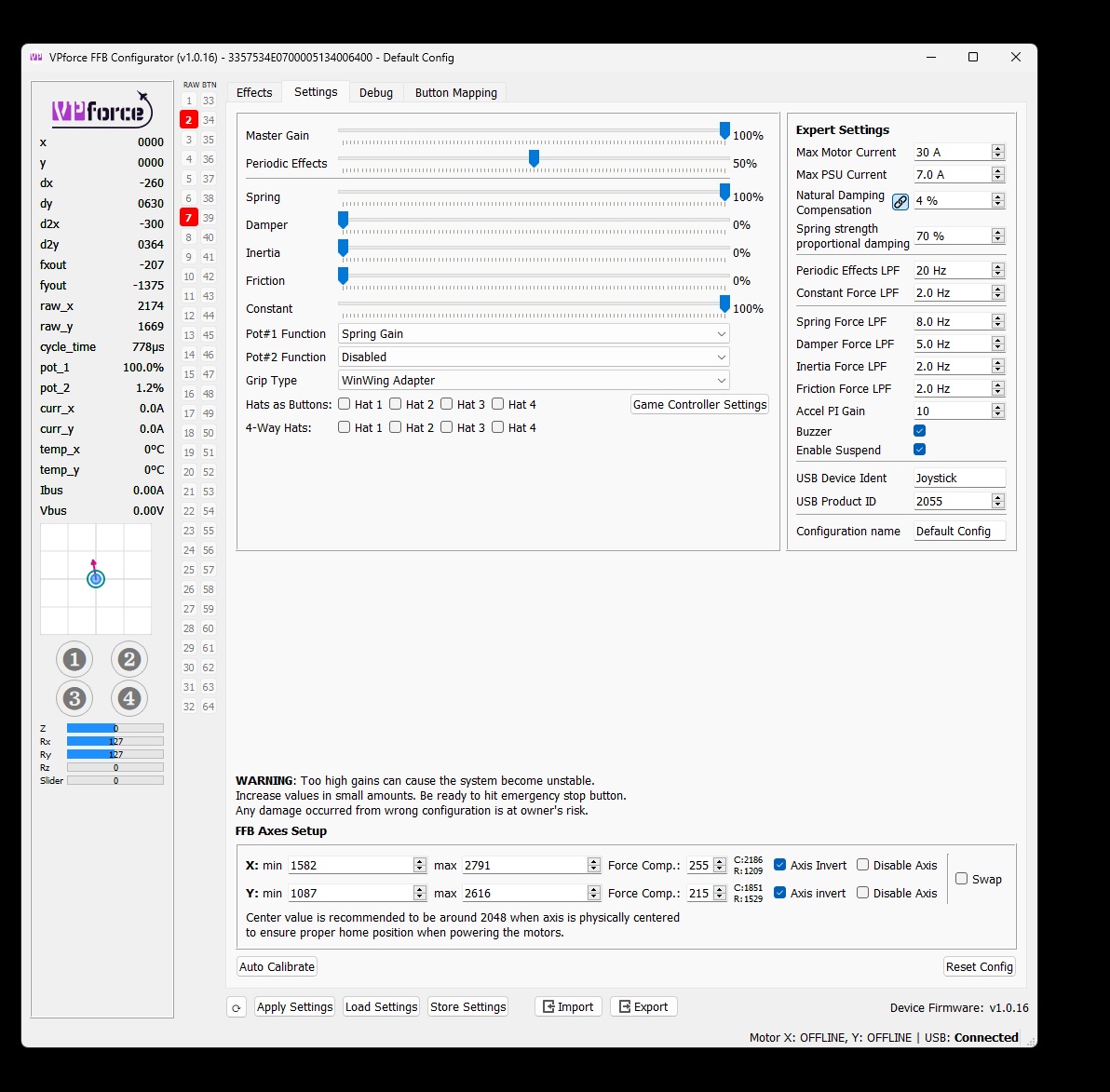

Walmis, this issue is back after updating firmware from .14 to .16, any idea what changed? Following your advice i was able to stop the crazy oscillations but they are back and its very violent if it accidentally happens.

Can you show your current settings?

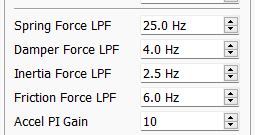

You can try increasing spring strength proportional damper to 100%-150%, Spring LPF can be reduced to 2-4Hz, and Damper LPF increased to 8-10Hz

Hmm does not turn off for me. Will check again tomorrow.

It should make the shutdown beeps once it detects a USB suspended state and stick will go limp

So no anti cog, just plain dead?

The older motor firmware did not have sleep mode, so it will still anticog.

Oh OK, then I seem to have a older one

But the saving is very minimal: 20mA vs 50mA

Good info about the oszillation above. Got pretty wild after update.

Yeah I was afraid that might happen, since previously math was a bit wrong, but the new settings should allow for better tuning

Will check tomorrow. Whole bunch of profiles to re tune

okay, spring strength porportional damper 100%, spring force LPF 3.0hz, Damper Force LPF 10 hz is working pretty good for me, not sure it was as good as before but its damn close. Increasing spring strength proportional damping to 150% caused the rhino to shutdown after a long beep after I rapidly moved the stick on the X axis. I think it just shut off the x axis motor after tripping a saftey of some kind?

Yeah, damper LPF is a bit too high in this case and it enters a high-frequenncy resonance during faster movements. Try reducing to 8Hz

There's a

Reset Motors button in the Debug tab to quickly reset the motors back to operational state anyone?

I promise, I searched. lol

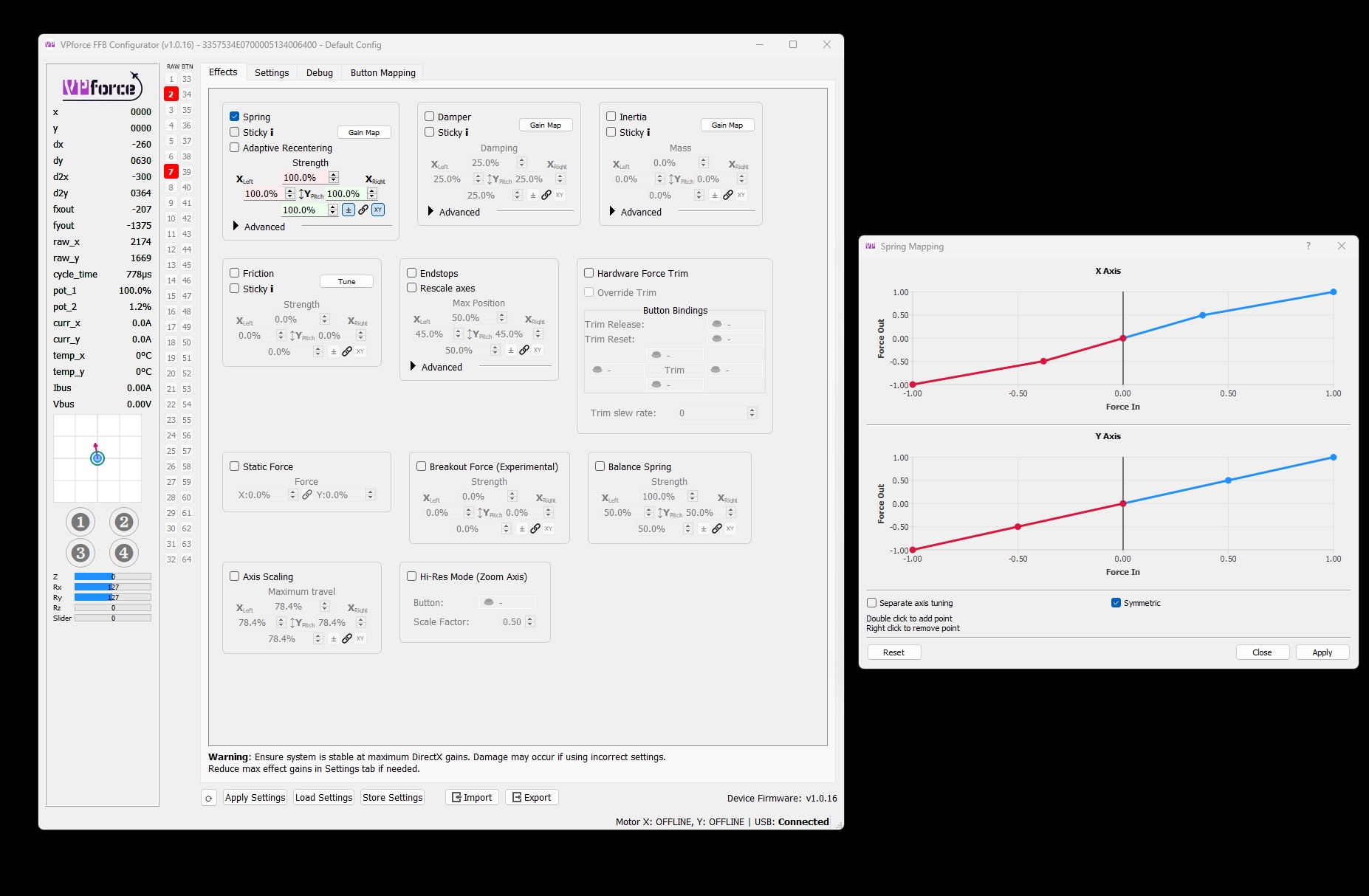

Breakout force. I was using this to help find and stay at center. But it doesn't work with trim. I know, experimental. But, seems like it was help hold center or trim center position really well.

Is there somewhere some documentation about the "Expert Settings" tab?

I'm by no means an Expert, but I figured out that I need to fiddle with these settings to stabilize my Rhino in certain profiles. I do this via trial and error, because I have no idea what I'm doing. The first 4 have like "tool tips" the rest doesn't.

I'm by no means an Expert, but I figured out that I need to fiddle with these settings to stabilize my Rhino in certain profiles. I do this via trial and error, because I have no idea what I'm doing. The first 4 have like "tool tips" the rest doesn't.

the LPFs are filters that reduce the bandwidth from respective controllers (Spring, damper, etc) signal going to the motors. The motor coils don't energize instantly, hence it's required to reduce the bandwidth to keep it stable.

Spring strength proportional damper is essentially damper force that you can adjust manually in Effect tab, but it's strength is automatically modulated related to the spring force gain, configured throw length, etc. i.e. the stiffer the spring the more the damper force is added.

So in short:

The damper LPF should be as high as possible, but too high will cause high frequency oscillations because the motors can't keep up with high frequency high amplitude torque requests and they will fail-safe.

The spring LPF + spring strength prop. damping - best be tuned to specific moment of inertia i.e. grip weight and extension length.

Spring strength proportional damper is essentially damper force that you can adjust manually in Effect tab, but it's strength is automatically modulated related to the spring force gain, configured throw length, etc. i.e. the stiffer the spring the more the damper force is added.

So in short:

The damper LPF should be as high as possible, but too high will cause high frequency oscillations because the motors can't keep up with high frequency high amplitude torque requests and they will fail-safe.

The spring LPF + spring strength prop. damping - best be tuned to specific moment of inertia i.e. grip weight and extension length.

Thank you. Reason I asked is, I have in some profiles a slight oszillation around center. If I stop it by holding the stick, and release it again, its fine but a slight touch will bring the vibration back. Wonder which would be the best parameter to conquer that.

That's the way to tune it, it should be resistant to such nudges. In any case try the defaults: 4Hz Spring, 8Hz damper, 100% Spring strength prop. damping

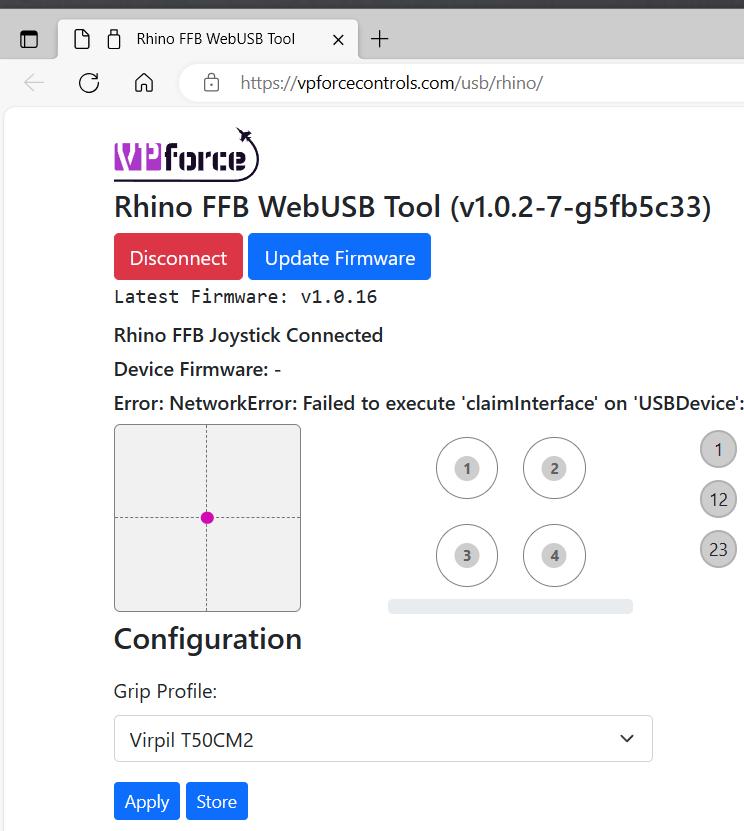

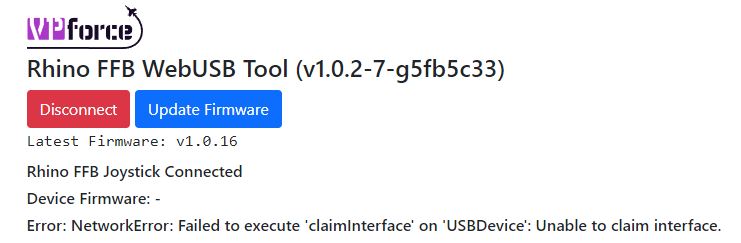

I can't seem to update my firmware. The stick works, shows in Win10, etc, but I get this:

Using Edge.

Disconnect/reconnect does not help. Power managent for USB disabled.

No Joy

Btw, you haven't changed this in the configurator?

Willdo. No.

Does it matter, whitch DIR to open the power shell?

No, just open as an administrator

Ok. I’ll try rebooting.

Great success!

Sorry if I am being dumb....see the new 1016 configurator software is out, but where do you get the firmware?

That same website where you download the configurator, acts as a firmware updater

thank you

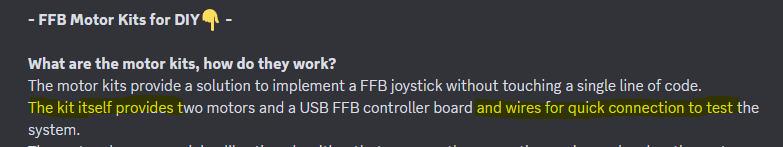

in the showcase there are only the Board and the motors at the pictures, but at the FAQ it's mentioned "and wires for quick connection to test" so I would think all necessary connectors and wires are included but I'm not shure, even less after your answer

biggest problem would be the 5pin mini-din cable to connect the Warthog grip, because I could only find 4,6 and 9 pin to buy

biggest problem would be the 5pin mini-din cable to connect the Warthog grip, because I could only find 4,6 and 9 pin to buy

There you go.....

These two together and a soldering iron....you are good to go.

https://www.digikey.com/en/products/detail/cui-devices/MD-50PL100/500828

https://www.amazon.com/gp/product/B09SX5LBRG/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

These two together and a soldering iron....you are good to go.

https://www.digikey.com/en/products/detail/cui-devices/MD-50PL100/500828

https://www.amazon.com/gp/product/B09SX5LBRG/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Keszoox XH 2.54mm Male & Female JST Connector Kit with 22AWG Pre-Crimped Cables Wire,(Total 90Pcs) 2/3/4/5/6/7/8/9/10 Pin Housing JST Adapter Cable Connector(5 Colors 150mm)

here's an additional source where I got mine... https://www.showmecables.com/by-category/connectors-adapters/din/5-pin-din

ShowMeCables

5 Pin DIN Connectors. Standard DIN and Mini DIN both available. Straight and panel-mount connector options. Available in 180°, 240°, 270°, and 360° styles in both male and female. Plastic and metal shell casing options. Same Day Shipping. Hassle-Free Returns. Lifetime Warranty. Live Support.

I'm getting this error trying to update the firmware

Any idea ?

Any idea ?

Ah, I just saw the same problem was already mentioned above, I'll try the given solution tomorrow.

with the firmware/software update, are these the new recommended settings for LPF?

or are there some new defaults that would be recommended

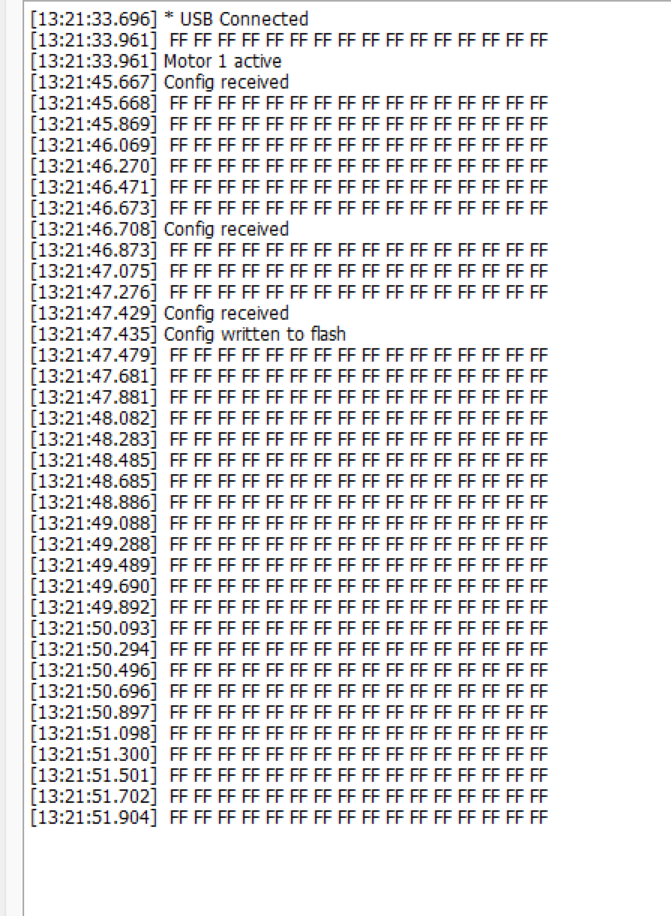

Hi, I just received the winwing adapter. But the button presses are not detected. I checked multiple times and the connection with the base seems good to me.

however i tested putting the debug grip.

And i see FFs only

however i tested putting the debug grip.

And i see FFs only

as seen in this image

I think i solved it...I had to unscrew the little spacer below the base of the adapter, maybe with it the pins didn't enter their holes.