Has anyone ever brake it like me?I have a 40cm extension and i broke it with the F4E

Has anyone ever brake it like me?I have a 40cm extension and i broke it with the F4E

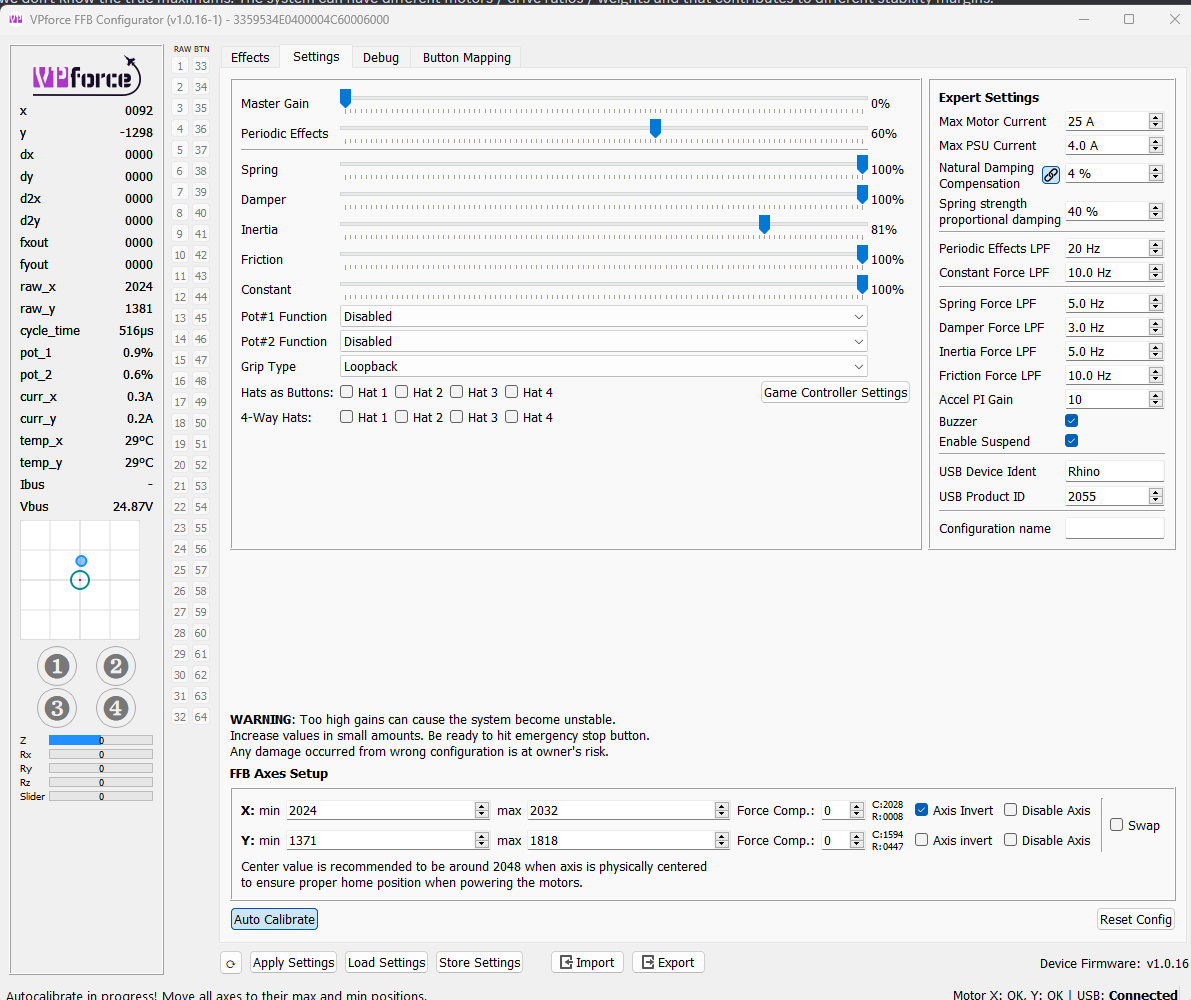

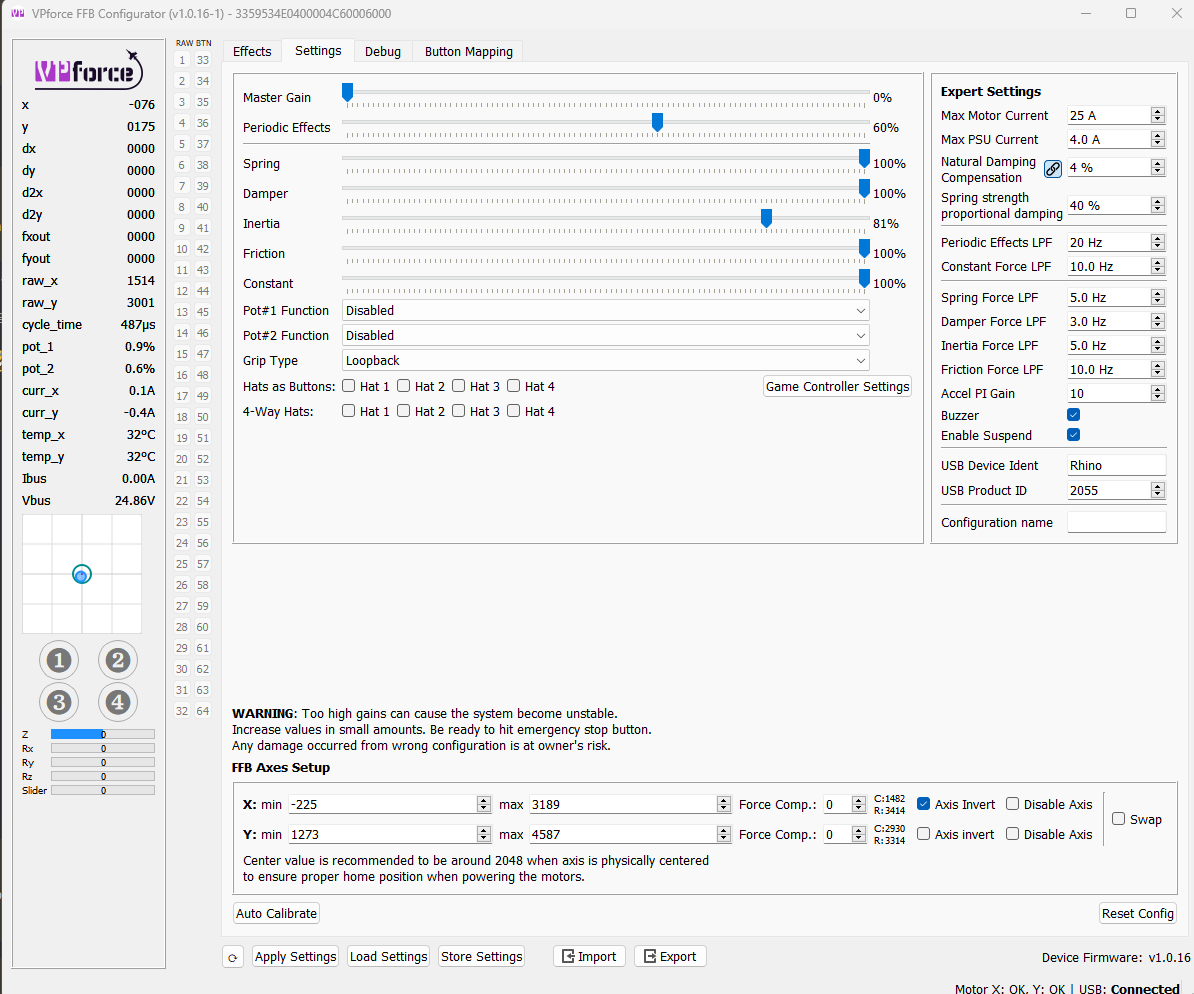

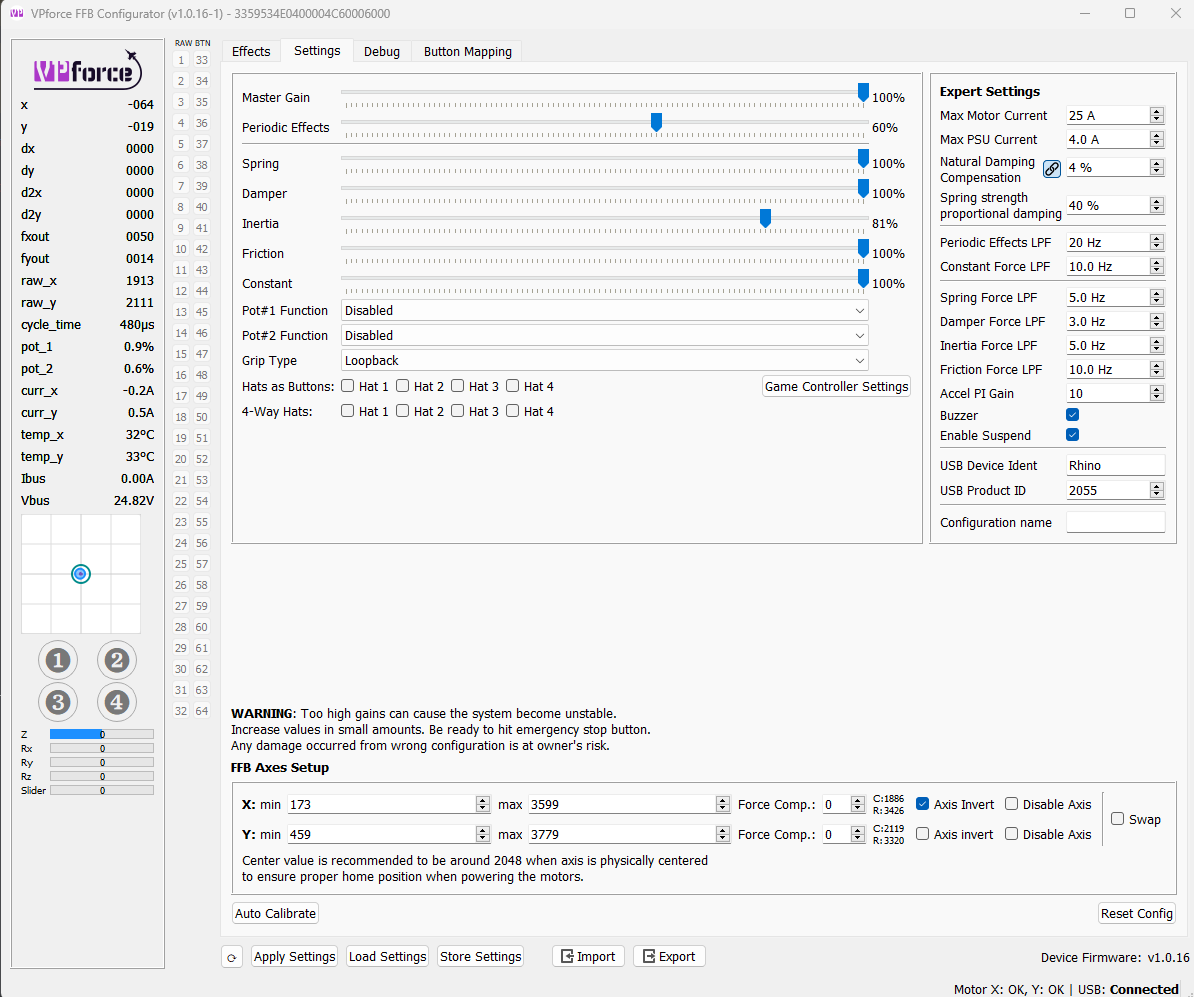

configs/RHINO-defaults.vpconf,

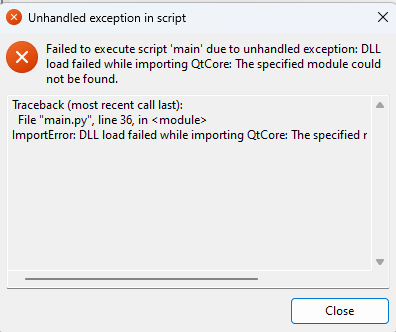

lol I was trying to run inside the folder but it works now

lol I was trying to run inside the folder but it works now

configs/RHINO-defaults.vpconf