Are these belt artifacts?

Struggling to get my VC4 hybrid to print at the quality of my VC3. One major issue I’m seeing are these artifacts. Is this from belt teeth? If so anything to help reduce them?

?Overextrusion? on small surface areas?

Probably someone has a good idea for me.

Seeing this ?overextrusion? on this small filled surfaces.

While wide and flat surfaces are quite good.

Flow and PA are calibrated and checked....

Z wobble only in one corner of the print

This print is getting a z wobble only on one corner of the bed. It could also be related to it being more of a x-move compared to the arc that comes before that corner. The arc portion does not have the same wall artifacts as the corner. Anyone have any thoughts?

Infill failure

I believe it's a retraction problem on my 3.1 500. But even after tinkering with it I still get constant artifacts flying off the print. I've reduced the extrusion to 96%. Printing PETG at 235. I did a calibration cube that came out great but this benchy is giving me problems when I get to the point it starts the infill. Any suggestions?

Elephants Foot

Just got my Vcore4 IDEX 500 running. Test prints at looking good, besides a little bit of elephants foot/first layer extrusion. I tried upping the z-offset in RatOS a little and changing elephants foot compensation in Prusa’s slicer from .15mm to .25 with little to no effect. Any other suggestions? Thanks!

Need help with print quality

Recently have assembled a VC4 500, managed to get it printing a model fully, but the quality needs work. The main issues are -stringing,

-poor ability to build bridges

-and visible layer lines.

Printing with PLA with 0,6 nozzle and using Orca slicer.

Are these issues solvable through slicer settings or could they be mechanical by nature?...

Purge blobs in the middle of a print

Hi, I have a RRVC4 300 hybrid with the stock rapido UHF and diamondback 0.4 nozzle and an orbiter Filament Sensor (without macros only as a Sensor).

I am trying to print with creality high speed PLA.

In the middle of a print, the print head would stop, purge some material and unload then reload that continue printing.

This leaves purge blobs all over the print and I can't figure out what's going on.

I'm using a quite conservative 30mm/s flow rate (in the flow rate test I got to 45 mm no problem) 210 C nozzle temp and 60 C bed....

Solution:

Then you 100% got friction problems with your PTFE ...

It goes more worse....

Hey folks...

I rly don't know what to do..

(RRvc4 hybrid 400)

I redo already the belt span... And measure it correctly......

Solution:

Okay folks... After a bit of research in my config files I found that the two Y motors was running at different amps.... Dunno how it happened...

I reinstalled ratos because I did not get any access to the configuration tool...

So I fixed the main problem with corrected settings on the motors......

Unknown printing Artifact PLS HELP!

I am experiencing this artifact shown in the picture and I have no Idea what is causing this or how to fix it... looks like the nozzle drags through the print... any suggestion on how to fix this? is there something like combing in cura for orca slicer, so the nozzle avoids prints? because only other thing I could imagine is causing this is overextrusion, but I calibrated my flowrate and PA with orca tools / ratrig tools, so it should be fine...

Idex T1 very different print quality

My T1 extruder (orange) produces very different results from T0 (black). Even when swapping filament, the results remain the same. Any suggestions as to where to look would be greatly appreciated.

Thank you...

Perfect First layer, disasterous second

Hello,

My first layer is almost perfect but the second is an absolut mess.

The building plate is preheted to avoid temperatur issues also tried different slicer settings. But it seems ratos shifts the second layer. Does anyone know how to solve this issue?...

Solution:

I fixed it, don't know why but prucasilcer is making weird thigs. Changed to Orca since then it is working flawless. Maybe if have to check all setting if something is different between both.

Bumpy edges on skew calibration

I’m trying to dial in my filament before officially putting in my skew calibration. I did all the calibration tests on orca. Tried a lot of things but can’t get rid of these bumpy edges. If anyone can point me in the right direction that’d be awesome.

If you’d like my filament and printer settings lmk. Otherwise I’m hoping it’s a common issue to fix. Tried google but couldn’t really find anything that matches. It is not z wobble btw. It’s not consistent and doesn’t show up on more organic prints....

IDEX Underextrusion

Anyone else seen this issue? VC4 500 IDEX setup and overall print looks good, except for pretty bad Underextrusion in areas of the print where the amount of filament laid down is relatively small...even with 1.0 extrusion multipliers, dry filament, reasonably fast speeds (300-450), and PA completely disabled. It's as though I'm losing nozzle pressure during the time it's parked and so it takes a little while to recover with proper flow. Thoughts??

Holes in Infill

I am running PA tuning right now with 15% infill and i discovered something that looks like underextrusion in the infill. Anyone has an idea what could be the cause?

I am using PLA for printing and am kinda struggling to get consistent and good results...

Solution:

It was a mixture of overcooling and too high printspeeds. Regular (not High Speed PLA) is hard to dial in. had to lower speeds to 80-100 to get some good results here. Cooling at max is 30% (part cooler is too STRONK! )

v-core 4 dragging nozzle through print

I've built a ratrig v-core 4 IDEX and have mostly completed the commissioning guide. Mostly, the printer appears to be working. Problems arise however, when I start printing.

The first layer goes down a treat and the second one looks OK too. But after that, the printer appears to be dragging the nozzle through the print. I can see the lower layers compress as the nozzle is laying down the next one. After stopping the print, I can see nozzle shaped indents all over the last layer.

I figured maybe something is wrong with a Z axis multiplier of some sort. But when moving the build plate 100mm up or down and measuring with a ruler, the movement distance appears correct....

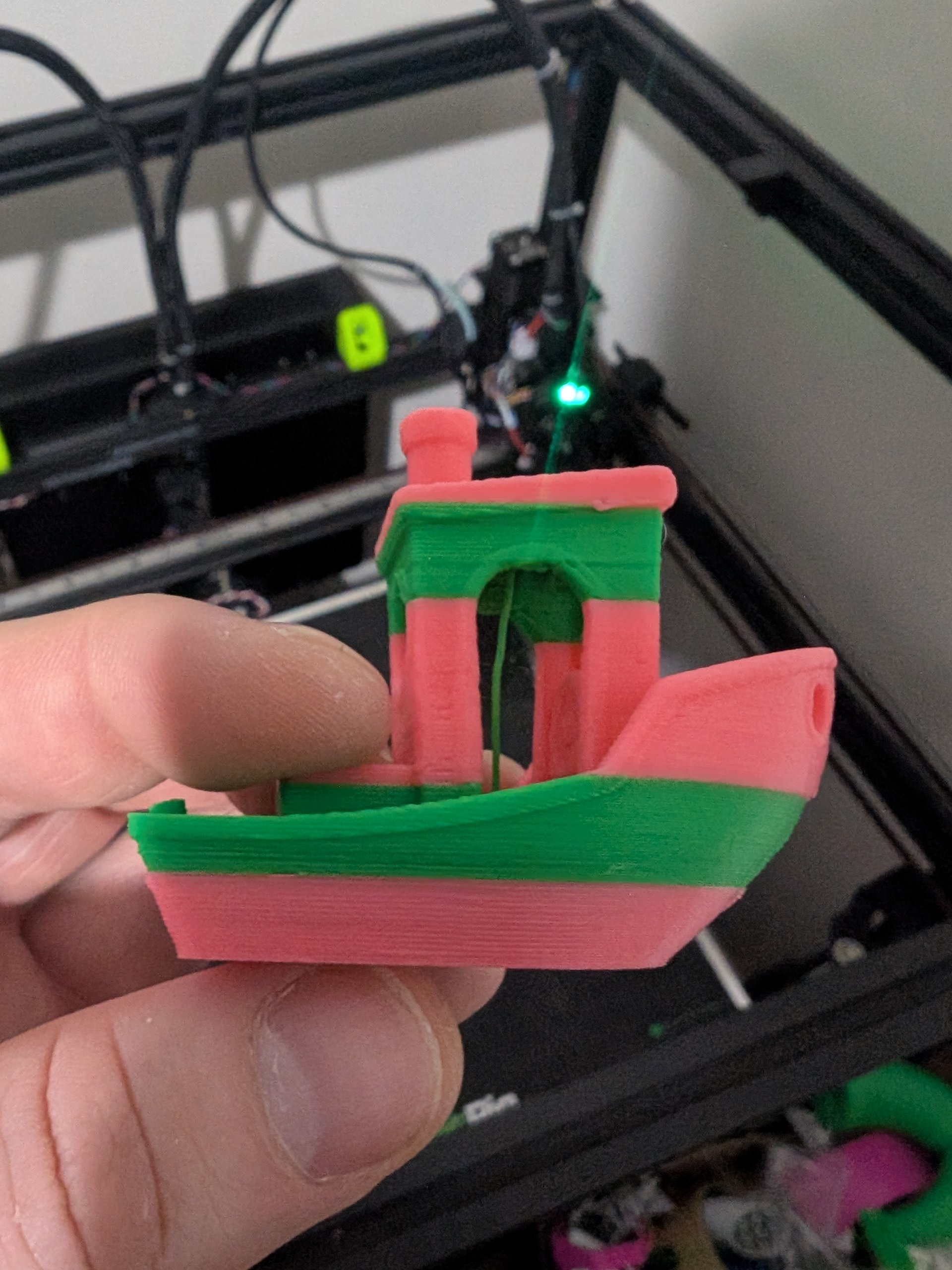

One color printing just slightly smaller on T1

What would cause my green to print just slightly smaller than the pink?

Other than this minor issue the IDEX is printing flawlessly 😀...

Dialing in ABS Settings

Im currently trying to dial in my settings on Hatchbox ABS. My bed temps are at 100C. Nozzle is at 225 for the first layer and 220 for the rest. Im fairly happy with the left side of the benchy but the right side seems rough. Im not sure if this is because of how the benchy is layed out in the slicer. The side that is rough is facing towards the back of the printer. Im not sure if I should continue to crank up the fan speed or lower the nozzle temp. I also attached my fan speed settings.

1mm Nozzle Seam Issues

I decided to try a 1mm nozzle on my VC4 and I'm really happy with how I've been able to get it dialed in, except for the seams. On the outer walls, I'm getting scaring (under extrusion) and on the inner walls I'm getting blobs. This is with Sunlu's High Speed PETG, using OrcaSlicer.

I've played around with retraction settings a bunch, and I've been able to improve the issue by bringing retraction down to 0.05mm (tried a range from .8mm to .05mm) and keeping extra length on restart at 0mm (tried a range from .8mm to 0mm), but I can't seem to solve the outer wall holes without making the inner seams significantly worse.

I have calibrated my flow, temp, and max flow rate using OrcaSlicer's calibrations, and I've disabled pressure advance for the time being....

Seam has consistent blob but not sure how to remove it

Machine: Core v4 500, toro tube and chube, 0.4 nozzle

External walls printed at 150mm/s with scarf

ASA material

What i've noticed is that the printer will sit at the seam for a split second which causes a smidge of oozing. I'm not at all sure what is causing it to sit at the seam but past that all other paramters appear great. the finish is good, layers are smooth. dimensions are within acceptable range for holes....

Non-ringing artifacts - what is it?

I'm getting these weird vertical lines in my prints, both in X and Y. After doing a klipper ringing tower test, I can conclude that they have the same frequency as the machine's ringing effect, but they're still there even after applying resonance compensation.

The first pic attached has resonance compensation turned off, and the second has resonance compensation (MZV) turned on. Ringing gone, vertical lines still there, both in X and Y...

Does anyone have any idea?...