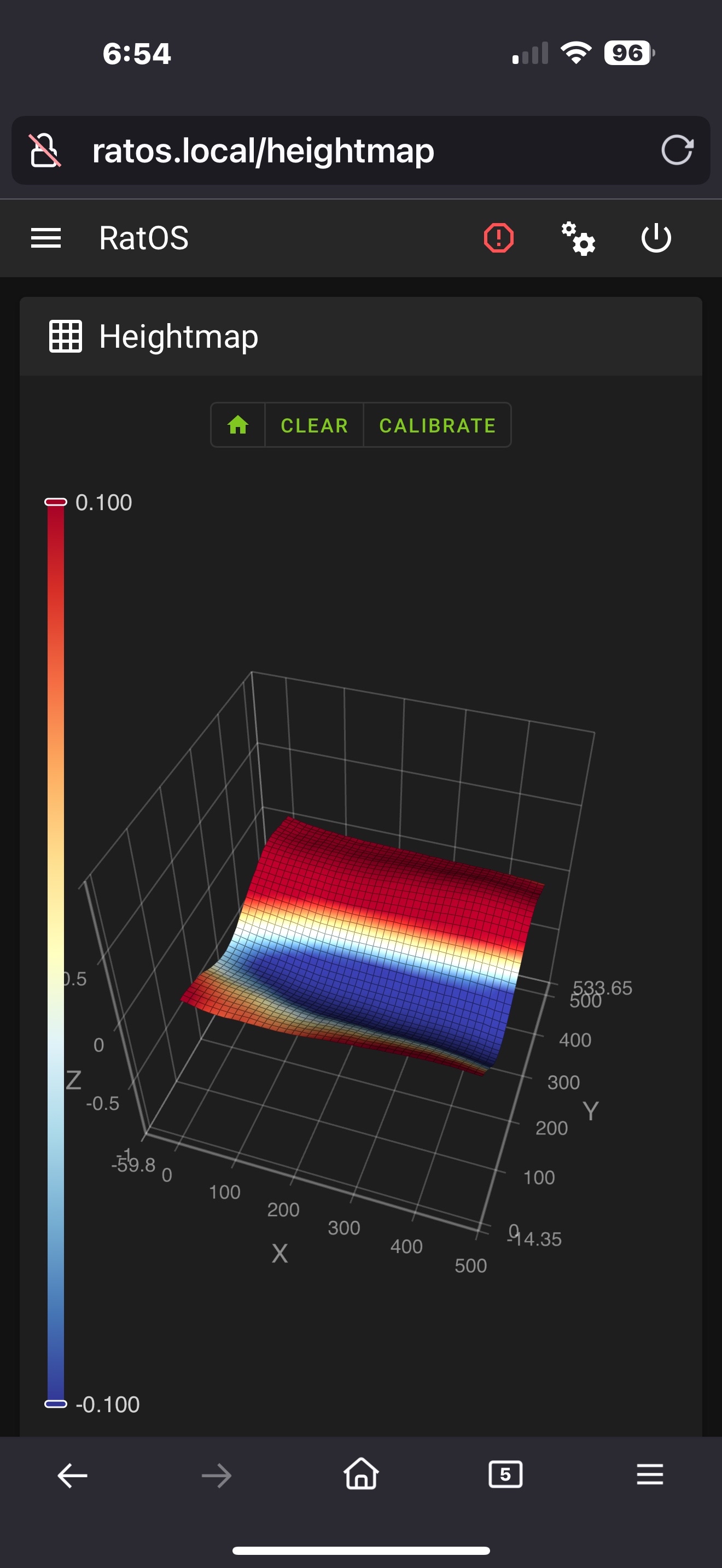

Stock bed shaped like a U

I finally got to the part where I setup the beacon for the first time and create bed mesh. VC4 500 IDEX. The bed has a serious physical dip on the right side. Straight edge confirms the valley on the top and the straight edge is like a see saw on the bottom hump. I have contacted ratrig several times with no answer. What do I do from here? I refuse to stick my heat pad or magnet to this bed as it’s so bad and you can visually see the dip without a straight edge. Here’s my graph.

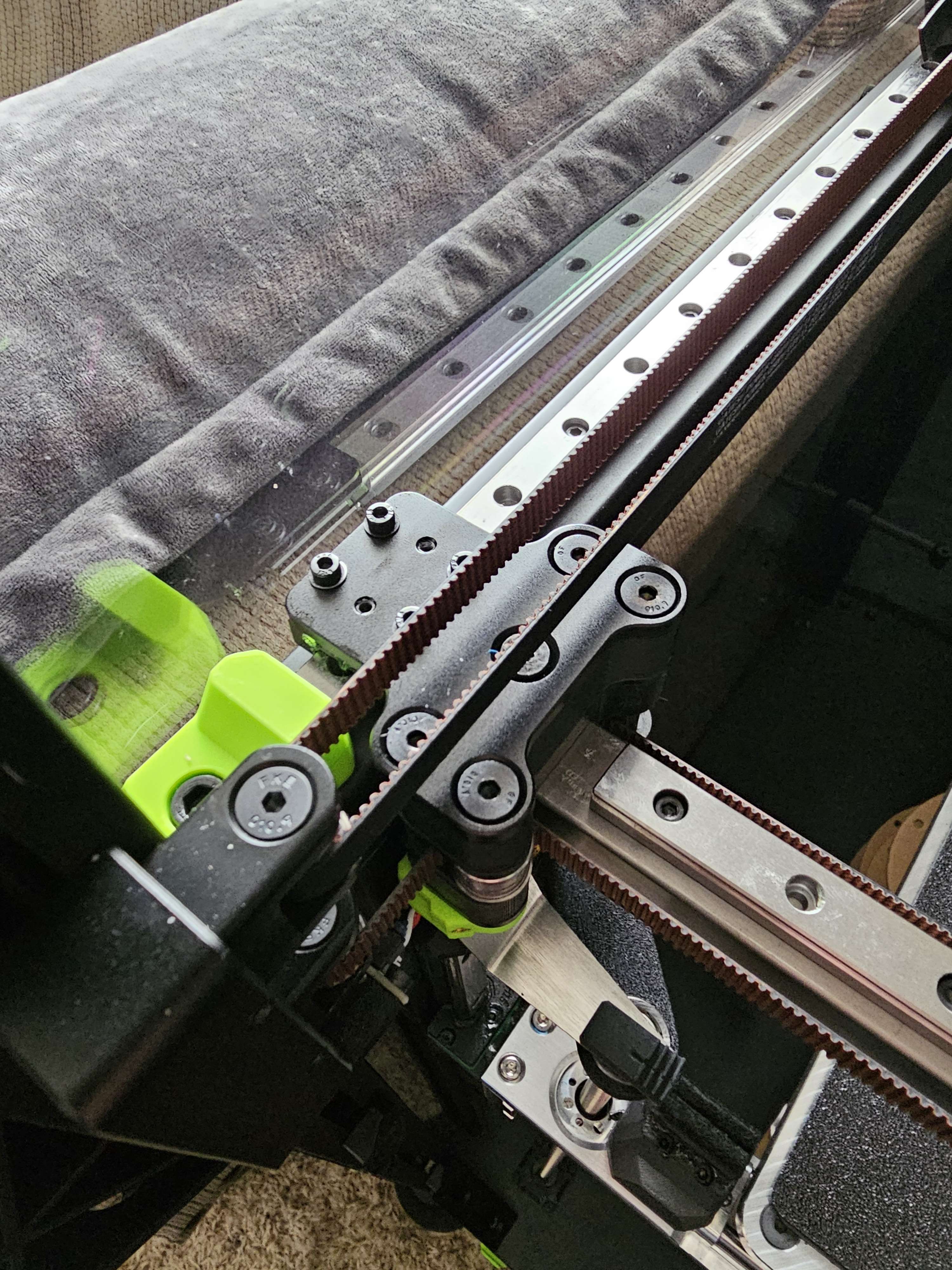

Help with gantry alignment

I recently got the Toro tube, and now every time I tighten the belts the alignment goes off, I used GATS and didnt have this problem with the original x axis, does anyone have a way to fix this?

Stripped screws holding Y rails

Hi everyone, I got a used V3.1 300 some time ago and while looking to fix the Y rails to get better bed meshes I stumbled upon like 4 stripped screws on one rails that won't budge: what would be the wisest option to take those out?

It seems like theyre extremely tight, and I've already tried:

- adding a rubber band to increase friction

- using biger allen keys (they're too big)...

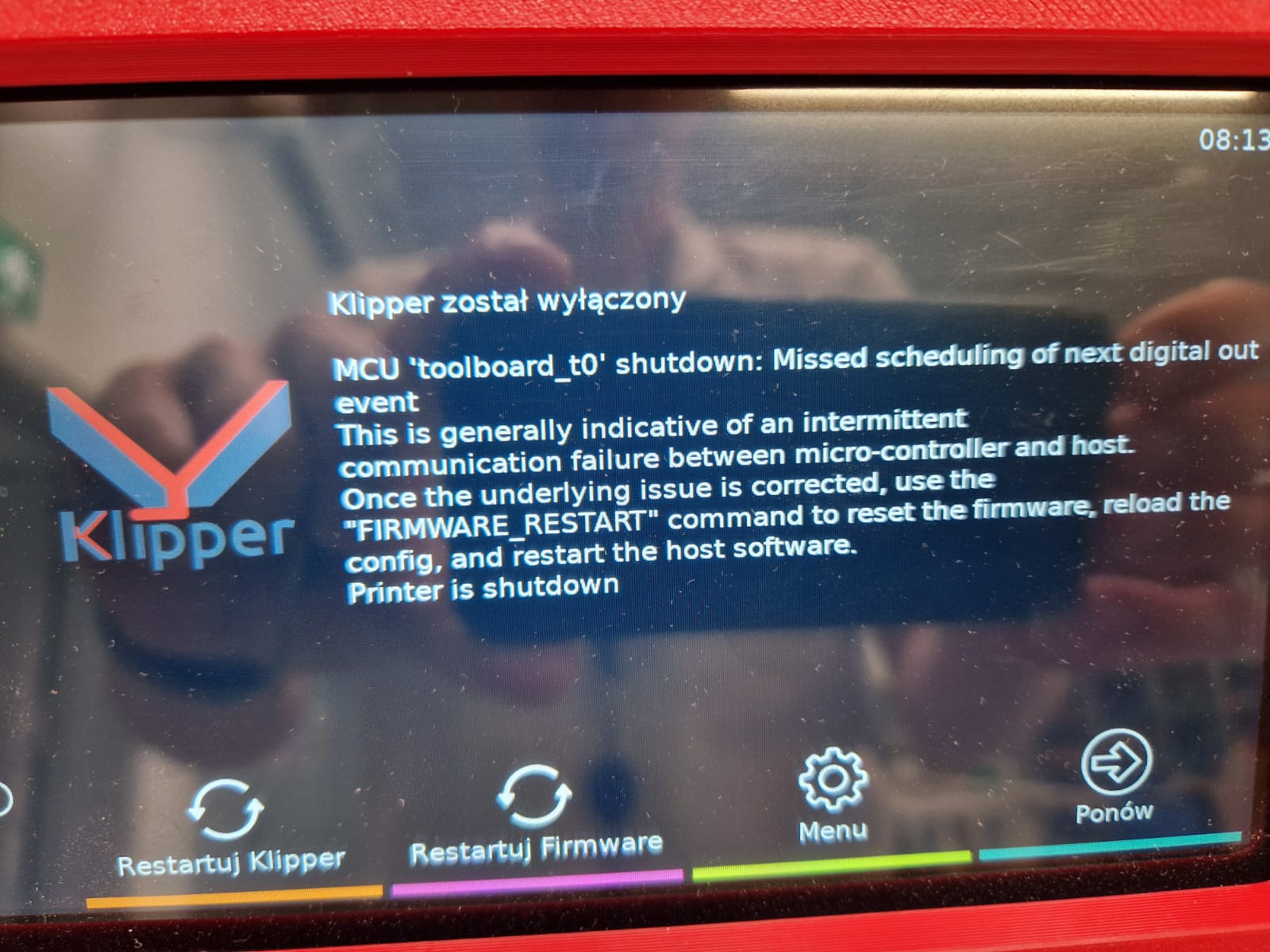

MCU 'mcu' shutdown

I haven't Printed in Months did not change anything and now every time i try to start a Print it says "MCU 'mcu' shutdown: Timer too close

This often indicates the host computer is overloaded. Check

for other processes consuming excessive CPU time, high swap

usage, disk errors, overheating, unstable voltage, or

similar system problems on the host computer....

Defective heat pad

I believe I have a defective heat pad. I tested resistance which was 0. Is there anything else I should test before ordering a replacement? Any experience on whether they would provide a replacement? I took delivery of the printer in December.

How to enable nozzle wipe

I have the two felt nozzle wipe pads on the left and right arm of my machine but they are not being used. I did some searching in the discord and found a few threads and copied "variable_has_front_arm_nozzle_wiper: True" to my "[gcode_macro RatOS]" section. They are still not being used. I do not see any other threads with solutions to this. Could someone please let me know what else I need to enable? Thank you.

Large nozzle extrusion issue

Trying to use a 1.8mm nozzle. Adjusted all the settings I thought I would need, getting this message when the print starts. Can anyone advise what to change to resolve this? Thank you.

Solution:

Anything you add into the printer.cfg will override existing values. So if they’re not in there already then you just need to add them with the desired values.

Another mysterious "Lost communication with MCU 'mcu' and 'mmu' and 'EBB'"

Hello all, I'm running VC3.1 on RPi4B+, Octopus PRO, Fysetc ERB V1 (ERCF), EBB36 and 1080p usb webcam.

All "big" things (servos, RPi etc) are powered off dedicated 24V-5V stepdown.

Recently I added EBB36, fixed problems with shutdowns due to EBB overheating and all was looking great. But I started getting "Lost communication with MCU '....'" error - all three MCUs lose communications at random. Webcam shutdown with "NO SIGNAL" on screen as well. Things I've done:...

Recently I added EBB36, fixed problems with shutdowns due to EBB overheating and all was looking great. But I started getting "Lost communication with MCU '....'" error - all three MCUs lose communications at random. Webcam shutdown with "NO SIGNAL" on screen as well. Things I've done:...

Not able to re-flash my Octopus V1.1 via any RatOS method

I've had consistent errors with RatOS and was advised to reflash everything. After re-flashing the pi, the version of the Octopus wasn't aligned but now I'm stuck in a "DFU not found" state while trying to flash the octopus. When it did happen to detect (not anymore), I remove the boot pin jumper, flash and get taken back to the same prior screen which tells me the versions aren't aligned after a few moments of "Flashing...". Has anyone else experienced this?

Adaptive bed mesh invalid coordinates

Getting this message while my printer is doing the bed mesh before the print.

@jLynx 🇳🇿 - VC3.1 Hybrid - 400

Adding the debug zip and a screenshot

v-core 400 3.1

ratos 2.1...

Vcore - 4 500 - IDEX the pause starts itself

Hi, I created the settings according to ratrig wifi, I didn't change anything anywhere and I have several problems. Sometimes a pause is executed independently, in the console there is no reason why the pause was triggered. When I put resume it goes, but again a piece of the perimeter is skipped. About twice it happened to me that when resuming after a pause it said the print was done, when it had about 10% of the print done. Once I turn off the filament sensors it is ok. Since I communicated wi...

unknown config object 'bed mesh'

VC4 is giving me this error upon booting. I have had it running and printing but start experiencing problems. I have reflashed my os and re did the configuration on hardware. I am now at this point and when trying to ssh into my pi it will refuse connection. Any help would be greatly appreciated, kinda stuck at this point. I came upon other threads with this but no solution was posted.

severe gantry twist and how to solve this...

Hey there...

VC4 300 IDEX.

I have a severe gantry twist. I had bad resonance screens and strange belt tention graphs as well.

So I did a bit of research and found the Gantry twist (Core XY + hybrid) from the commissioning guide.

To tell you in advance, I did purchase the printer used, so I did not built it myself......

How do I stop my printer waiting in the middle once the print starts?

From the video you can see it does its prime blob and then goes to start but sits there while the bed cools from from 61c to 60c but in that time it causes a bunch of oozing. Is there a way I can fix this?

Solution:

Found the issue. In SuperSlicer, I had to uncheck this. Its not needed since our start gcode handles it

Beacon lower than nozzle

Was having first layer issues when I realized my beacon is much lower than my nozzle. There is no way the nozzle will be close enough to the bed without the beacon scraping. Can someone help me understand what I did wrong?

Solution:

I had to redo my mesh after adding the UHF extender, that was the issue. Working now

Beacon is scaning offset

I need som help with my beacon. Since i installed it and reflashed the printer, something is not right with the offset. Heres 2 videos.

This is a stock v-core 3.1 1 is doing z-tilt, u can tell its offset in the x axis to the right...

This is a stock v-core 3.1 1 is doing z-tilt, u can tell its offset in the x axis to the right...

Orca Slicer not uploading to VC4. Error 7. Network unreachable.

I deleted my main 0.4 nozzle preset profile in orca slicer and now orca wont upload to the printer. I have confirmed the ip address rat.os local and it says its connected and working. The device tab also allows me to operate the printer still as well but still cant upload. Any help would be appreciated!

V-Core 4 IDEX Setup shows two T0

The setup shows two T0 toolboards and doesn't allow finishing the setup.

How can I fix this?

I found a post with the solution to run through the configuration again, but where can I restart the complete configuration?

Kind regards Sorkana...