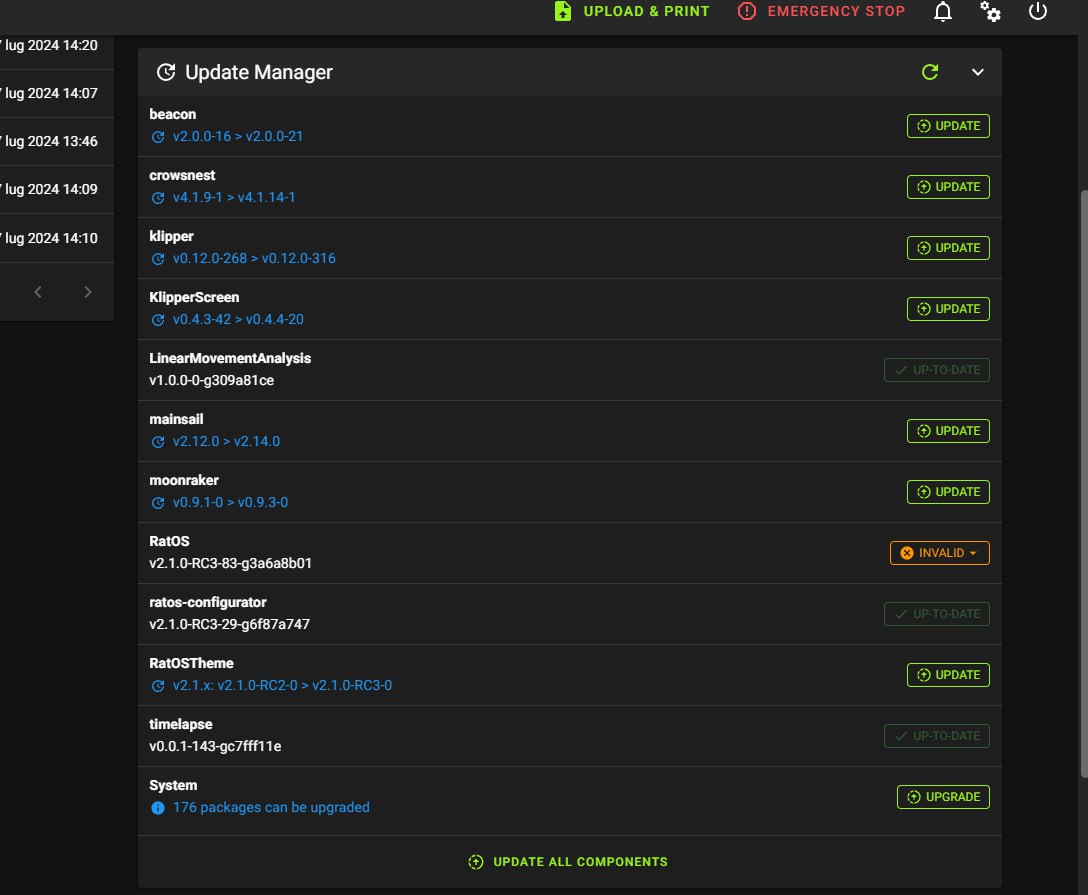

RatOS-invalid

Have tried the version of RatOS 2.1 and followed the guide but still ended up having problems.

Used Rufus to flash the sd with the image we downloaded from github at the link in the guide. Attached you find the folder used.

Then we proceed by upgrading the software packages:

Since I found both ratos and ratos-configurator in the list (RatOS prior to V2.1.0-RC4), we started by updating ratos first, then ratos-configurator. Ended up stuck with the upgrade of the configurator....

Beacon is not triggering on new build

I'm just finishing my vcore 4 idex build. I'm to the point of calibrating the beacon probe but it doesn't trigger. I have to emergency stop before it crashes.

It is connected to the Pi via the included USB cable in the kit. The red light illuminates as the build plate gets close. I have "beacon" selected under the probe drop down in configurator.

If i query_beacon, it returns unknown command. It seems like it isn't enabled in the firmware and I'm not sure how to fix it....

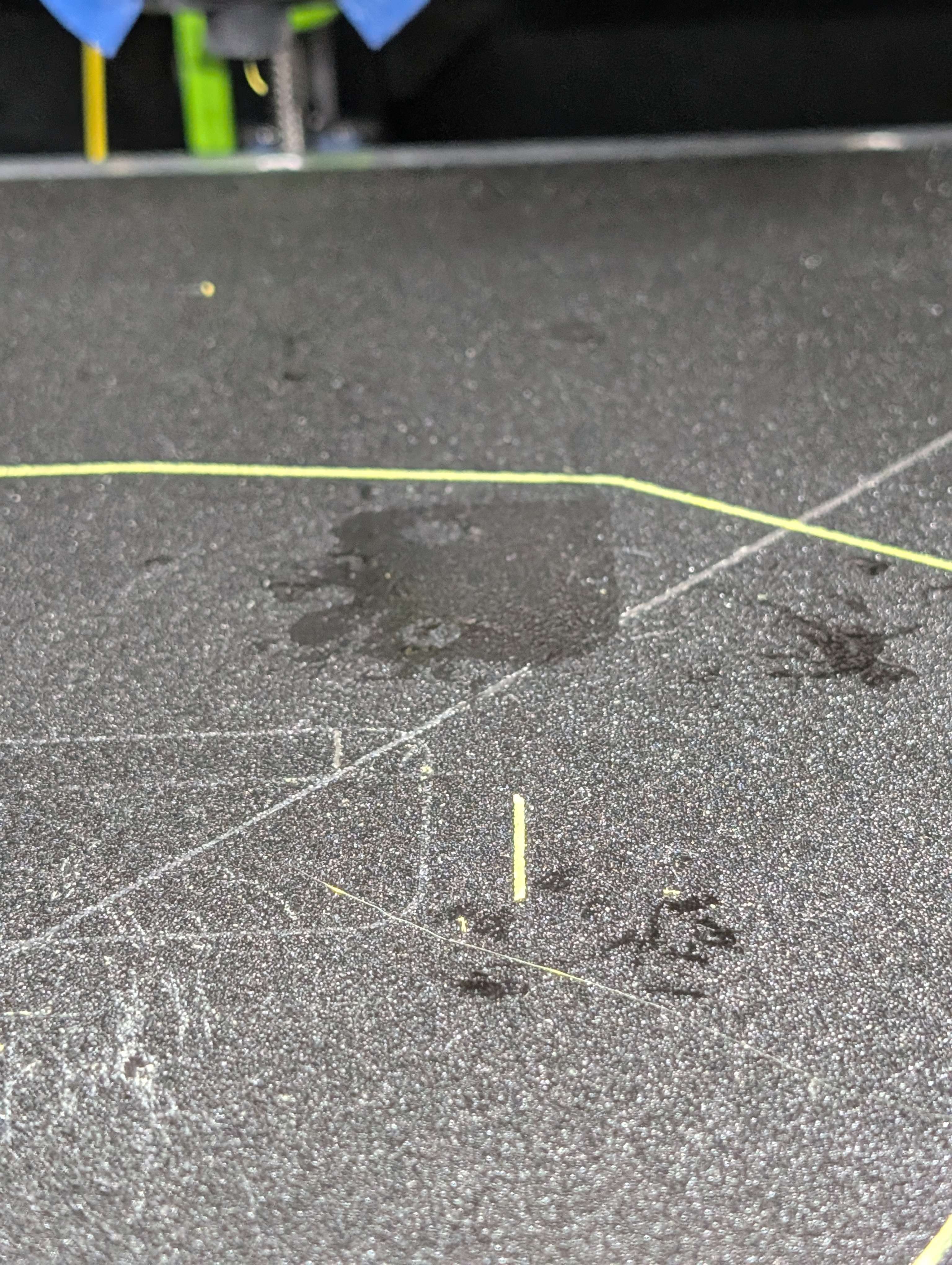

Pei sheet sweating weird sticky/glue like texture

I wanted to Print asa so I heated the bed to 110C and the sheet started sweating this weird sticky glue like texture

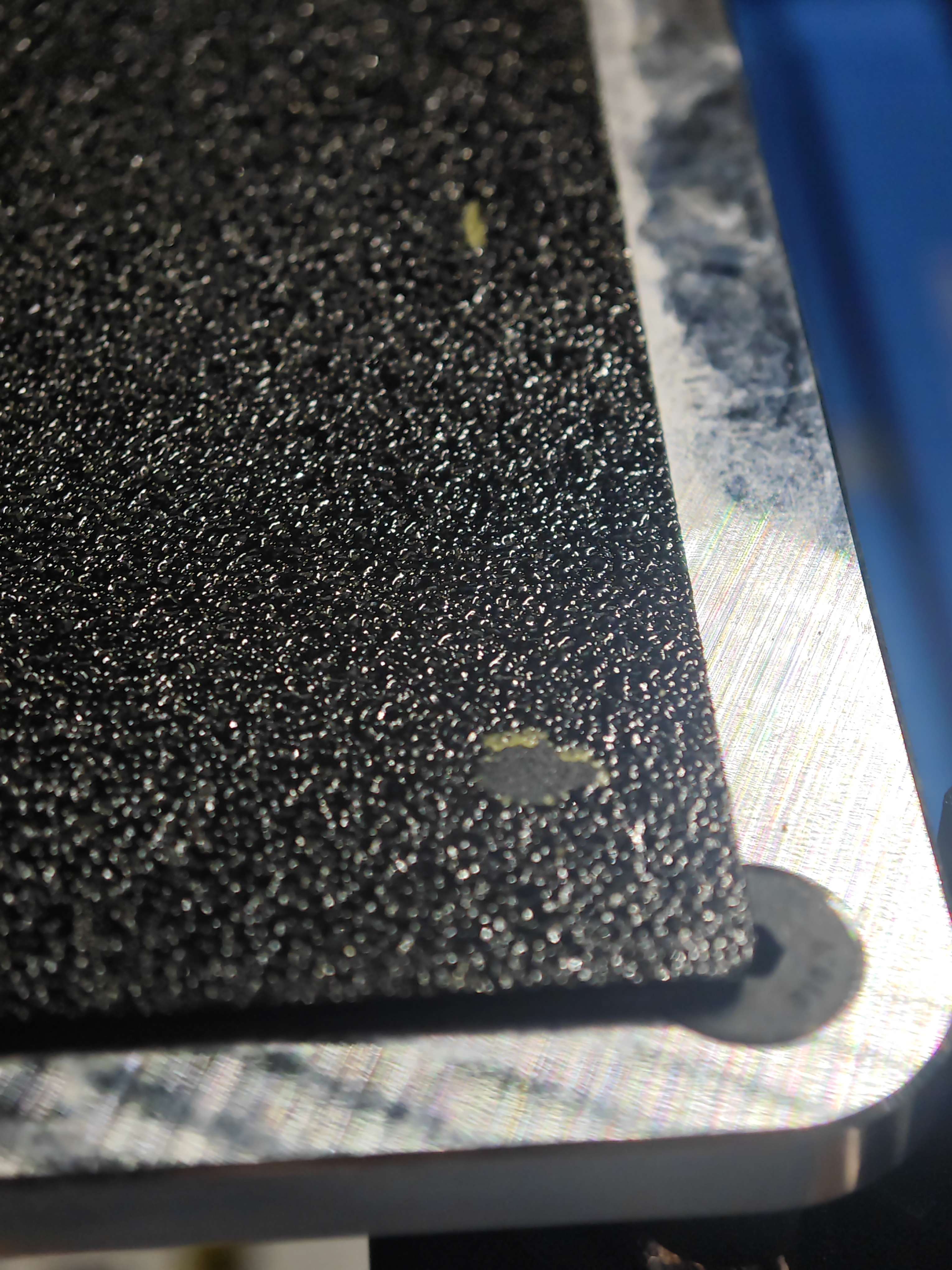

Peeling pei on prime blob

Hey. Do you guys have the same with v-core 4? My pei is peeling of with prime blobs

Vcore4 IDEX - Part fan cooling stopped working

I have been printing alot of high temp filaments where part cooling wasnt relevant but recently tried to print PLA and had to find out that the part cooling fan on both toolheads wont turn on no matter what.

Now smart as I am I reset the whole printer and tried debugging everything only to realize that I did not make a backup.

I know the fans worked previously (hard to overhear when they spin up).

The voltage supply works and I have checked with my multimeter that both fans get a 12 V supply.

The white PWM cable however does not seem to do much i.e. looking at it with my oszilloscope i can see a 50 Hz signal but not in any way shape or form the PWM cycle....

Solution:

Apparantly many moons and many more coffees ago I had decided to wire the Ground wires of the two fans into HE2 and HE3 respectively. This worked quite well for all this time but apparently somewhere along the way (maybe a firmware update of the octopus board) the board changed its behavior to output -24V on the - pin ~ Or this was something i set in my config file and forgot about.

Resonance in X and Y (VFA‘s ?)

Hello I don’t know what I can do to get off this pattern. I already have installed the toothed pulleys but it isn’t getting better.

Tested various speeds but nearly the same result.

I have an Ratrig VC4 300 and have installed the kraken motors (hybrid)...

Commissioning RR500 IDEX T1 error.

When moving direction of the X and Y all is working correctly. When I do BEACON_INITIAL_CALIBRATION X-Y and Z move correctly including T0. However, T1 will just stay at his location and just make noise (brrrrr) like it one to move but nothing happen. I have added a video that shows what happen. Any help is appreciated.

Cant start sliced files with 2 extruder

Hola,

when I slice and upload a file to my vcore 4 idex it shows this error message :

Error evaluating 'gcode_macro START_PRINT:gcode': jinja2.exceptions.UndefinedError: list object has no element 1 (attached the klippy log)

This only happens when the slicer uses the second toolhead. With only one Toolhead sliced, it works just fine....

Vc4 keeps crashing

My core 4 keeps crashing many hours in to a print. It gets a significant way through a 2 day print and keeps just becoming non functional. Klippy log doesn’t show any klipper errors. I have to restart the printer to gain connection as I can’t ssh or browse the mainsail interface when this happens. Does anyone have any suggestions on what to check as I’ve currently wasted 5 kg of filament trying to solve this

Head moves in X and Y instead of just X

Greetings.

As the headline already says. The Toolhead moves not just in X but also is pulled in Y when I tell it only to move along X.

I am trying to figure out why but so far I could not.

I attached a short clip, as I do not know how describe it better....

Help with BTT Microprobe

i have been trying to get this damn probe to work and for the life of me nothing i do works. i though it was supposed to be as simple as :[include microprobe.cfg]

and that would do it but clearly i have done something wrong again lol. i have tried so many different combinations that now i don't know which way is up or down any help would be greatly appreciated...

Probe samples exceed sample_tolerance

Got the new beacon revision , I am trying to recalibrate my system and during the auto calibrate it kept failing. After many hours and physically checking the printer, verifying that their are nothing in the way of the nozzle I started calibrating it manually step by step.

During the thermal expansion is when it always fails. I PID my nozzle 2x and when it checks the nozle is withing 1.5+_ degrees of the target 150/250 but still fails. Initial and other calibrations work. Its just during thermal expansion that its too large...

Error Cannot translate accelerometer id to Klipper accel sensor name

Upgraded my beacon and wanted to use the configurator to add the accelerometer feature but i get this error. Wont show my current config vs my old one. Im thinking this is the new config that has the issue?

Vcore 500

RATOS 2.1 R3-29(newest)...

Solution:

FYI backedup my working printer.config , and i just went ahead and accepted the changes anyways. Went back to the configuration and my printer.cfg was left alone and only the 2nd time did it want to update it. So its safe to just accept it FYI. Will mark solved.

Loss of connection on long prints

In long prints of more than 20 hours or in pauses of more than 3 or 4 hours, when I try to access mainsail I get a connection error, I have been experiencing the problem for some time, I have tried to increase the idle time out and to install sonar to keep the connection active, but nothing solves the problem. I have also noticed that when I get this error the raspberry pi does not appear in the list of devices connected to the router.

vaoc Questions/Issues

I have a VC4 500 IDEX. My VAOC seems to be working and loading fine. When I try and calibrate the nozzles using VOAC, i have to go back and forth between T0 and T1 and whenever i switch back to the last one, it doesn't line up ever. I go back and forth and back and forth and they are never lined up. They are close sometimes but never lined up. Then I hit the square to finish. Am I only supposed to go to each nozzle once and line each one up once then hit the square? Or should they eventually lin...

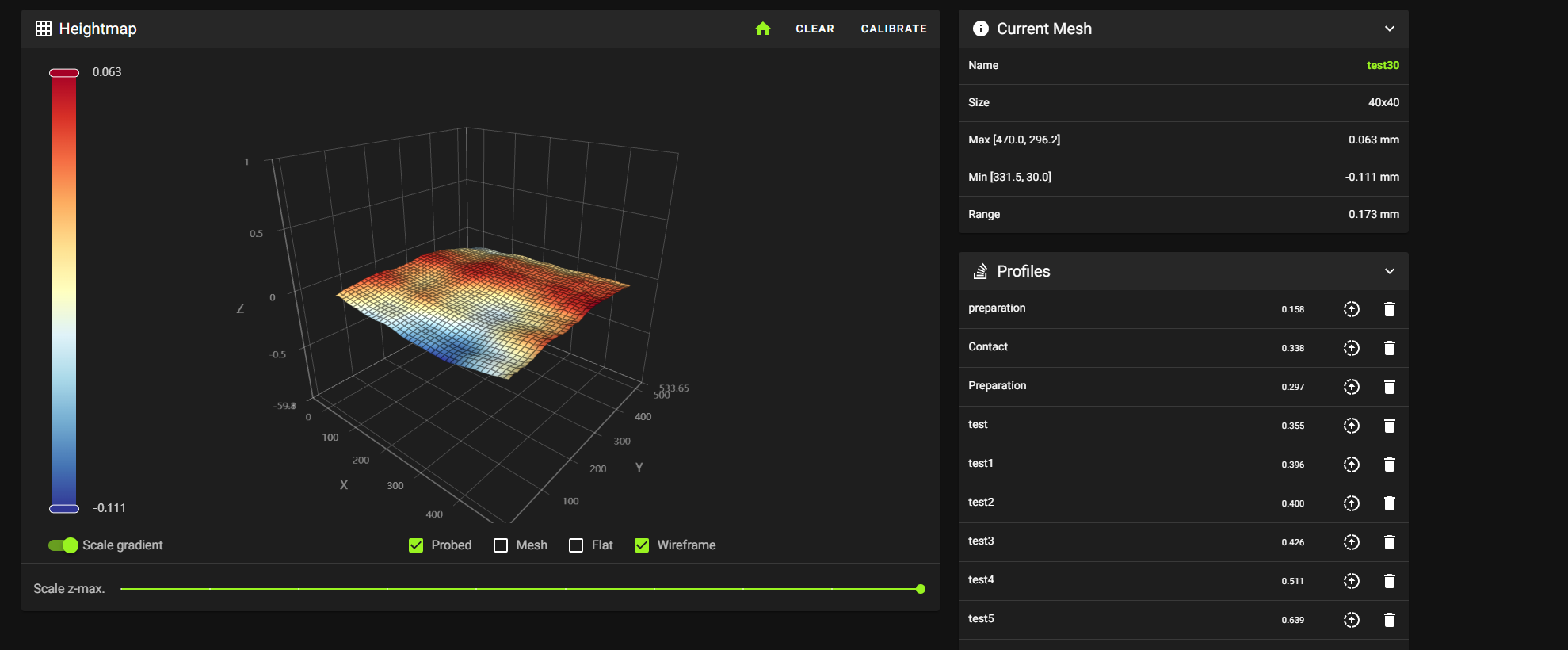

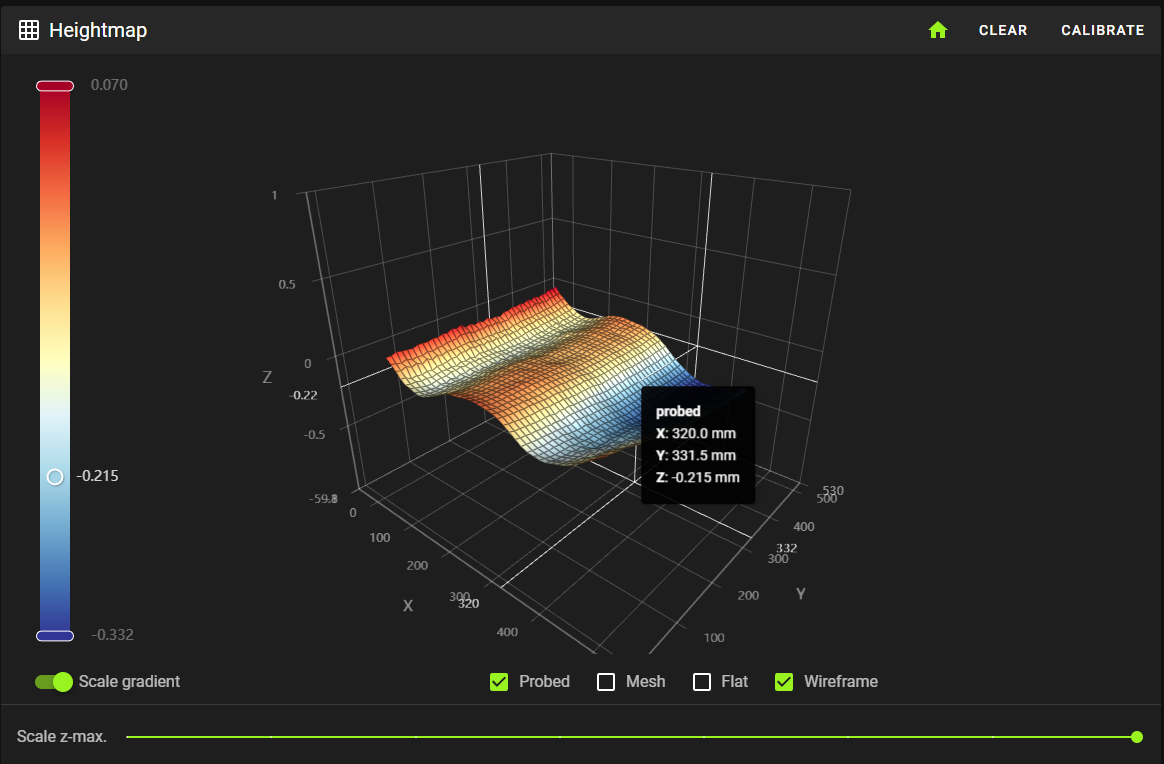

Toro Tube generating wavy heightmap - fix?

I'm terribly spatially dysfunctional (I have trouble visualizing things in space).

I did major rebuilds of my Vcore4 500, including adding Mandala Rose Works joiners with a Toro tube. Pretty sure the Toro tube is bowed / U shaped.

I'm now seeing wavy heightmaps. And struggling to understand what this translates too - Kapton tape on the gantry on the low sections? High? Or other?...

help after calibrating beacon, printer seems to be reading all Z axis values incorrectl

Seeing some stange behaviour with my printer, curious if this may be something easy. I've had a very difficult time getting my beacon sensor to finish the

When the

BEACON_RATOS_CALIBRATE command successfully. It ended up being the z1 gantry was not straight and once I fixed this, everything worked perfect. Now though what IM seeing is that the scans in HEIGHTMAP appear that they are reading off by 0.5mm or so. Basicallly if I have the Flat option checked in the display, I will see what looks like I'd expect with the PEI sheet on, but it's all showing everything .5mm off from the flat section. not a corner, or 2 corners, but I mean the whole thing is registering like it's offset .5mm. The little lip at the top is just the PEI sheet and Im not concerned with or trying to fix that, it's the fact that it's reading what appears to be everything offset from the bed. I took the PEI sheet off and I get the same results with the range I'd expect., but iwth this strange .5mm (or so) offset. I really noticed this because I ran BEACON_MEASURE_GANTRY_TWIST and it gave me this message:

removed this because it was too large, going to put in a reply

removed this because it was too large, going to put in a reply

BEACON_RATOS_CALIBRATE ran successfully, it did not report this at all. Though the range from min to max was about the same, it was relative to 0 and it reported it as a Low gantry twist. Because those numebrs don't have anything close to 0, or even any negative numbers is why Im thinking there is some kind of offset happening. I'd note this all happened after I did the VAOC calibration. After the BEACON_RATOS_CALIBRATION succeeded,. I moved to complete the VAOC calibration and it failed with some out of range errors, and then all this has measurements with some kind of offset started to being.

Any help / guidance would bew appreciated....Parking and Load position calibration

im following the 15. IDEX Accessories and the commissioning guide and got to the VAOC tab and visual calibration. I got webcam stream not found. what do i need to do now?

Help with idex vcore4

Hello, Finished my idex build yesterday. All the ratos setup seemed to have worked. Flashed all boards successfully.

The problem I have is, I get no camera feed from the vaoc on the printer or pc. My pc can see the camera but no video. I can also control the vaoc led.

The only endstop that's working correctly is the Y estop. The others say they are engaged all the time. Cant control the hotend fans. Also only have a red ring on one of the runout sensors....

Very High Gantry Twist

I can't seem to remove my gantry twist. I have taken the belts off and made sure the gantry strikes both sides at the same time. loosened the xy-joiners to while lined up at the back to make sure they are aligned. Loosened an retorques the y-rails making sure they are straight. A billion heightmaps. Shimmed my x-rail. Adjusted frame. Lowered and raised feet. Checked Beacon. It seems flat to me. I'm not sure what else to look for.

V4 500mm

Toro Ti Tube

MandalaRoseWorks aluminum everything...

Solution:

Only change was my build plate. Seem crazy to me but I'll take it!